Sunshade plate mirror cover sliding fatigue test machine

A technology of fatigue testing machine and sun visor, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problem of mirror cover not being able to pull back and forth normally, cost, time and resource waste, mirror cover, and cylinder air pipe freezing To achieve the effect of improving test ability and test efficiency, saving test time, and adapting to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

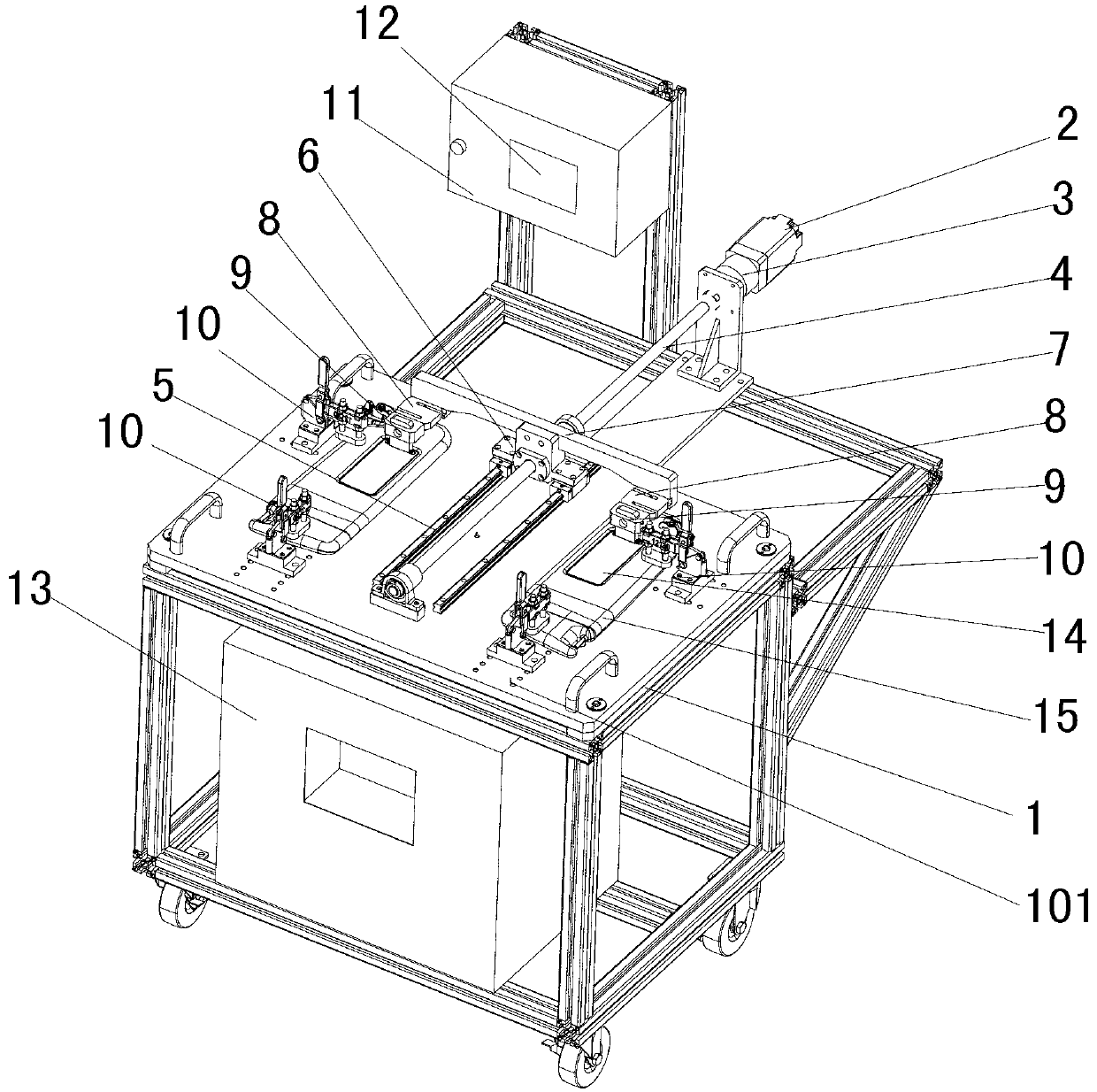

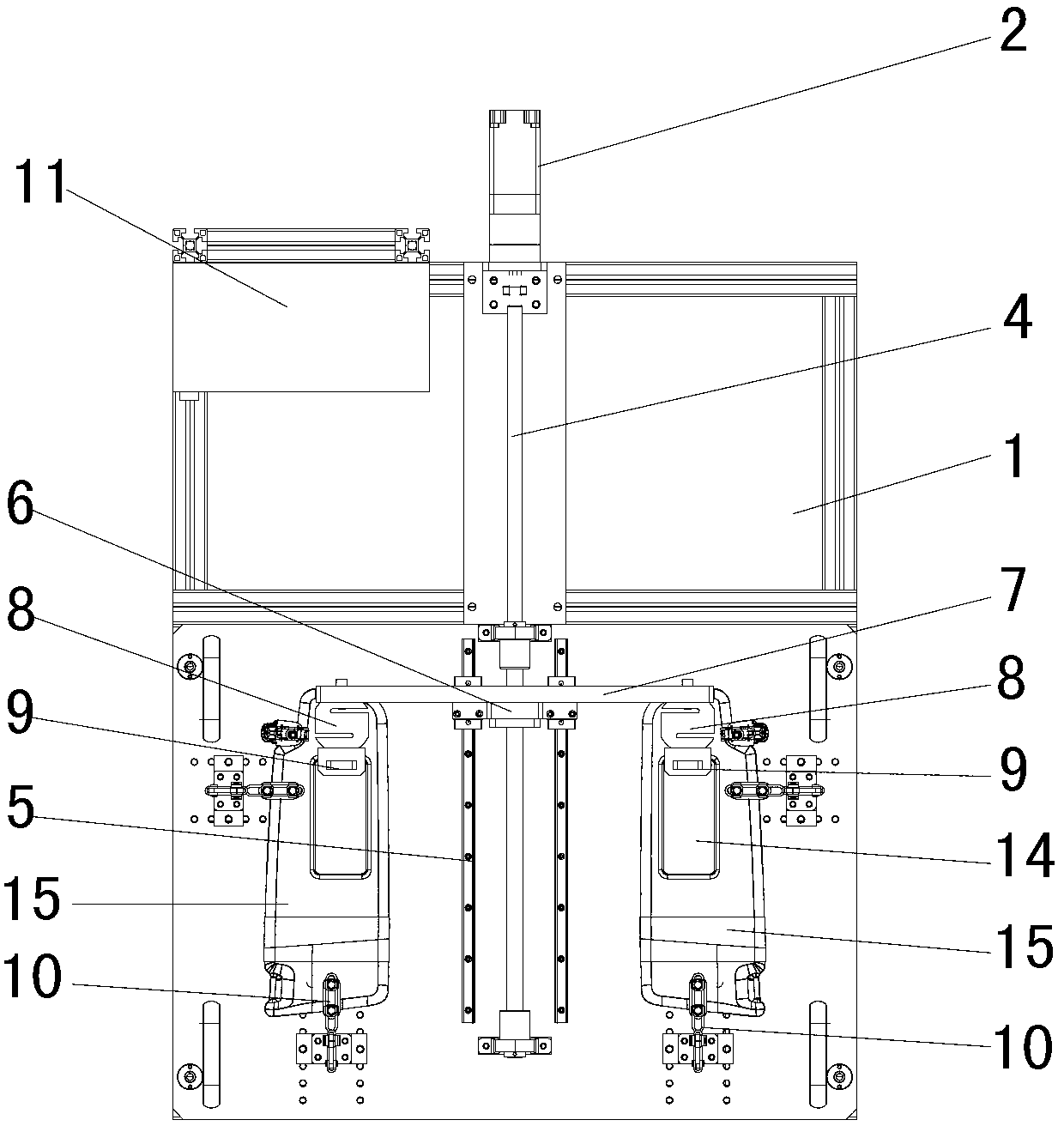

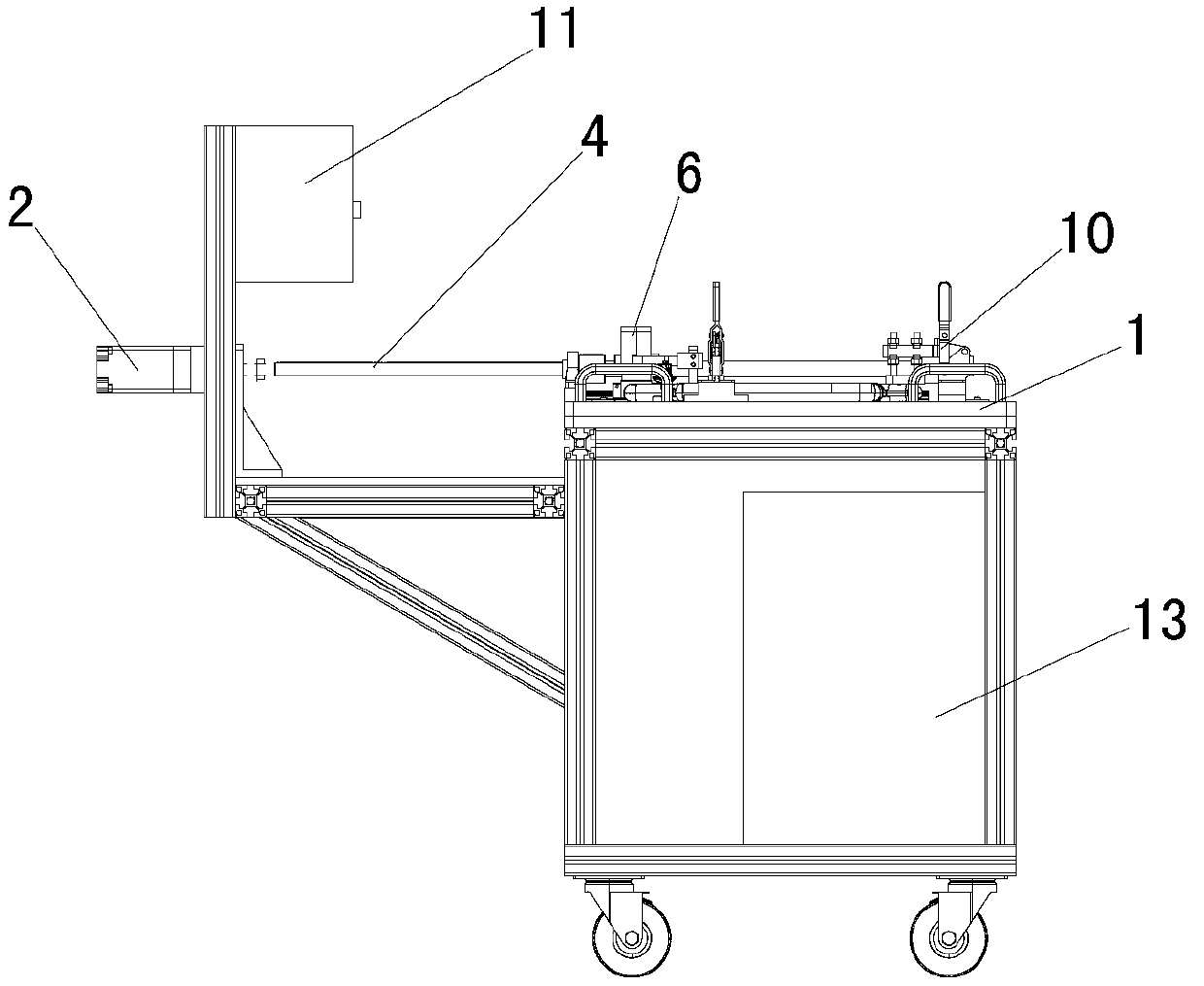

[0025] see figure 1 , figure 2 , image 3 , the sun visor mirror cover sliding fatigue testing machine of the present invention comprises a machine platform 1 and an electric mechanism arranged on the machine platform, a transmission mechanism connected to the transmission of the electric mechanism, a mirror cover sliding mechanism with sensors, a sun visor pressing mechanism, a PLC , touch screen and industrial computer.

[0026] The electric mechanism includes a servo motor 2 and a reducer 3, and its power output shaft is connected with a ball screw 4 as a whole.

[0027] The transmission mechanism includes a ball screw 4, a linear guide 5 and a slider 6. The ball screw 4 is connected to the electric mechanism for transmission. The linear guide 5 is installed on the machine 1. The slider 6 is erected on the linear guide 5 and is set on the ball screw. On the rod 4, the positive and negative rotation of the ball screw 4 drives the slider 6 to move forward and backward alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com