Method for manufacturing plastic basket

A manufacturing method, a basket-and-basket technology, applied in the direction of sustainable manufacturing/processing, containers, bio-packaging, etc., can solve problems such as not found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

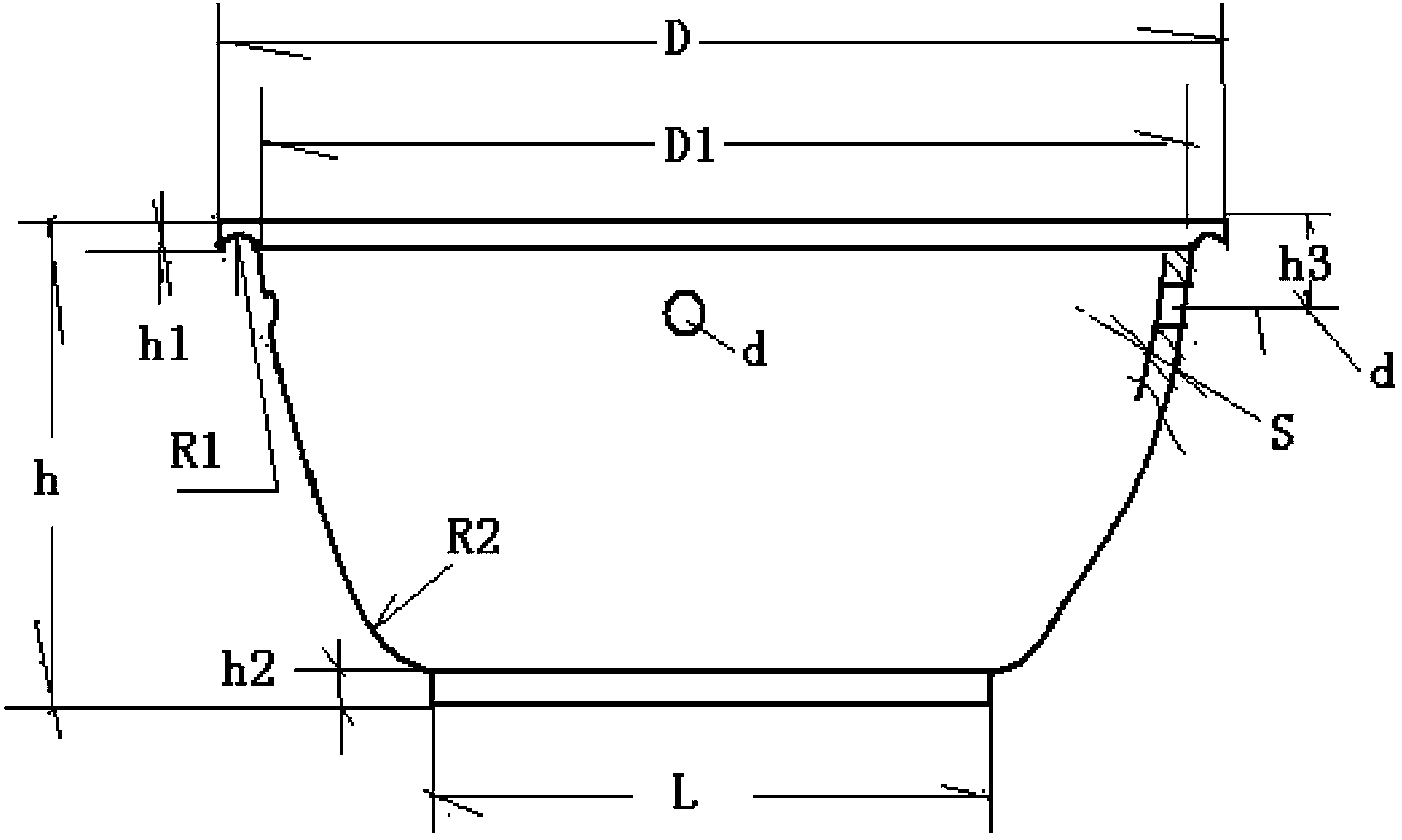

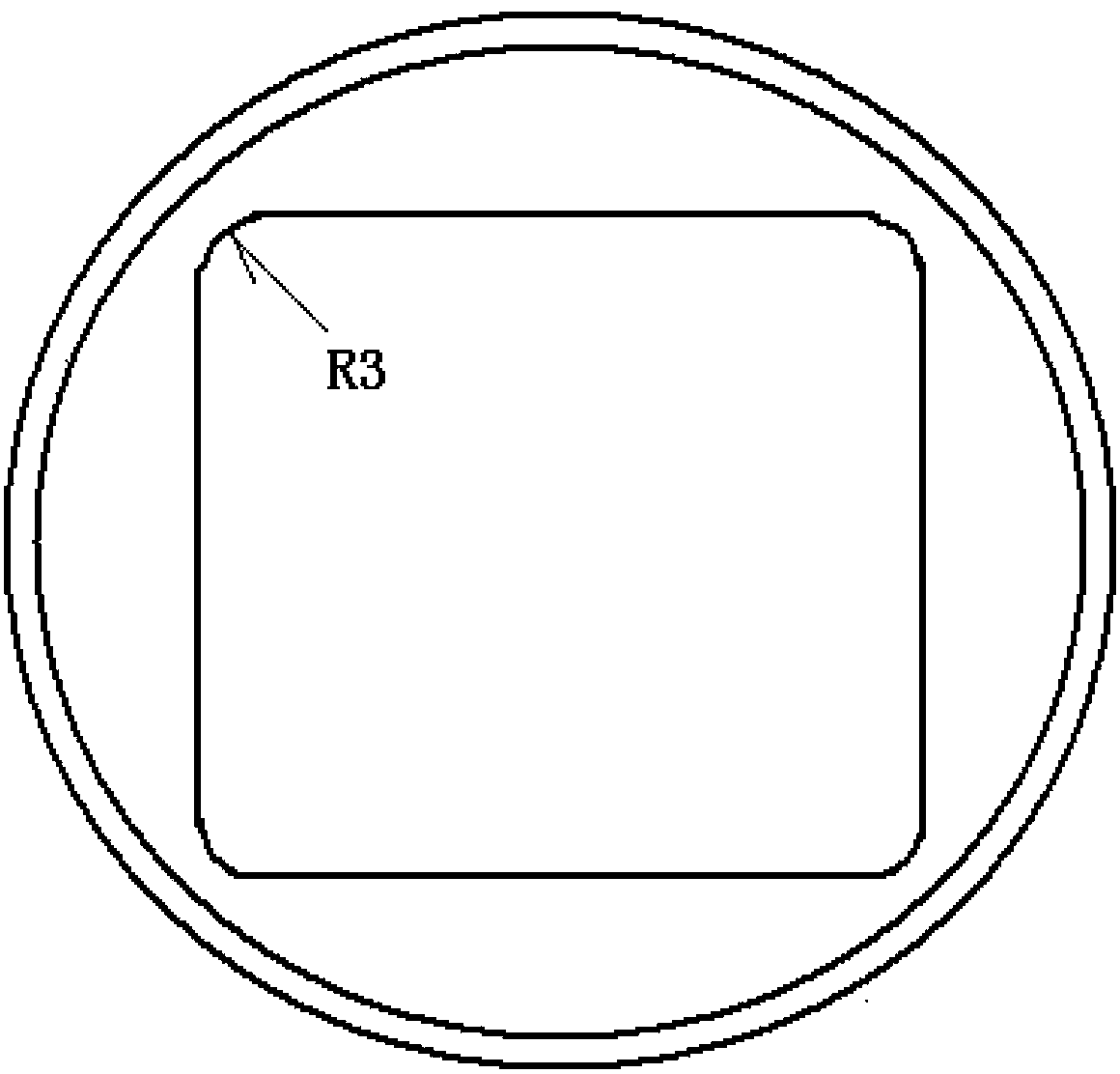

[0011] Such as figure 1 , 2 As shown, the manufacturing method of the plastic basket of the present invention, the inner diameter of the barrel mouth (D1), the straight diameter of the barrel edge (D), the height of the barrel body (h), the thickness of the barrel body (S), the thickness of the barrel edge (h1), the barrel foot Outer side length (L), bucket foot height (h2), rope groove semi-diameter (R1), bucket body cylinder and square tube bottom transition arc connection semi-diameter (R2), bucket foot side semi-diameter (R3), rope hole (d), rope hole distance (h3).

[0012] In the manufacturing method of the plastic basket of the present invention, the basket is a hollow barrel-shaped structure with an upper circle and a lower portion. The outside of the bottom is provided with a bucket foot formed by a raised square side, the circular bucket mouth is provided with a bucket edge, and on the cylindrical part of the bucket body, there are 4 rope holes (d) evenly distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com