Multi-needle-bar sewing machine

A technology for sewing machines and multi-needle bars, which is applied to sewing machine components, needle holders for sewing machines, sewing equipment, etc., can solve the problems of high manufacturing cost, high machining accuracy, complex structure of double-needle bars, etc., and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

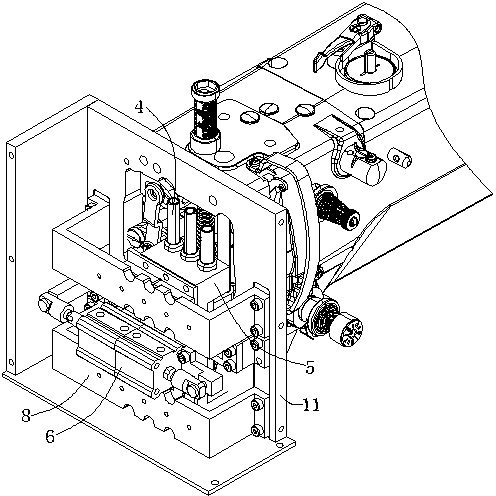

Image

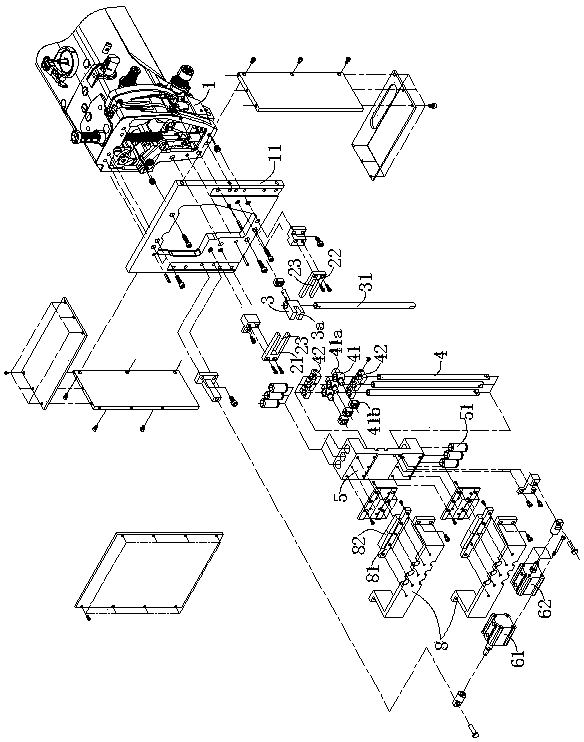

Examples

Embodiment 2

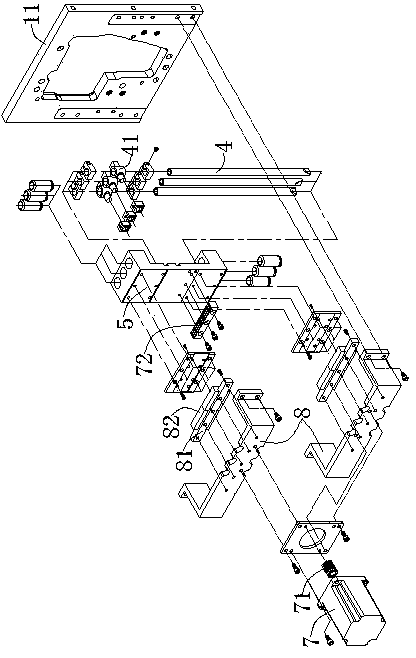

[0038] This embodiment is based on Embodiment 1, and the driving mechanism has been improved. Such as image 3 As shown, the driving mechanism of this embodiment includes a motor 7 , a gear 71 connected to the motor 7 , and a rack 72 arranged on the needle bar mounting frame 5 and meshed with the gear 71 . By controlling the rotation angle of the motor 7, the needle bar installation frame 5 can be controlled to move among the three travel positions, so as to select the corresponding needle bar 4 to snap into the slot 3a. For the driving mechanism in this embodiment, the needle bar installation frame 5 can also be moved between two or more travel positions, so as to adapt to needle bar groups with different numbers of needle bars.

Embodiment 3

[0040] In this embodiment, on the basis of Embodiment 1, the number of needle bars in the needle bar group is reduced to two. The driving mechanism adopts an air cylinder to control the movement of the needle bar installation frame 5 between two stroke positions.

Embodiment 4

[0042] In this embodiment, on the basis of Embodiment 1, the number of needle bars in the needle bar group is increased to four. The driving mechanism adopts a structure in which three cylinders are connected in a straight line, so that the needle bar installation frame 5 can be controlled to move between four stroke positions. Each cylinder of the drive mechanism can also guide its movement through the guide rail and slider structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com