A protective sleeve for high voltage cables

A technology for protecting bushings and high-voltage cables, which is applied in the field of power equipment, can solve problems such as power loss, insufficient strength, and potential safety hazards, and achieve the effects of reducing heat generation, improving safety performance, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

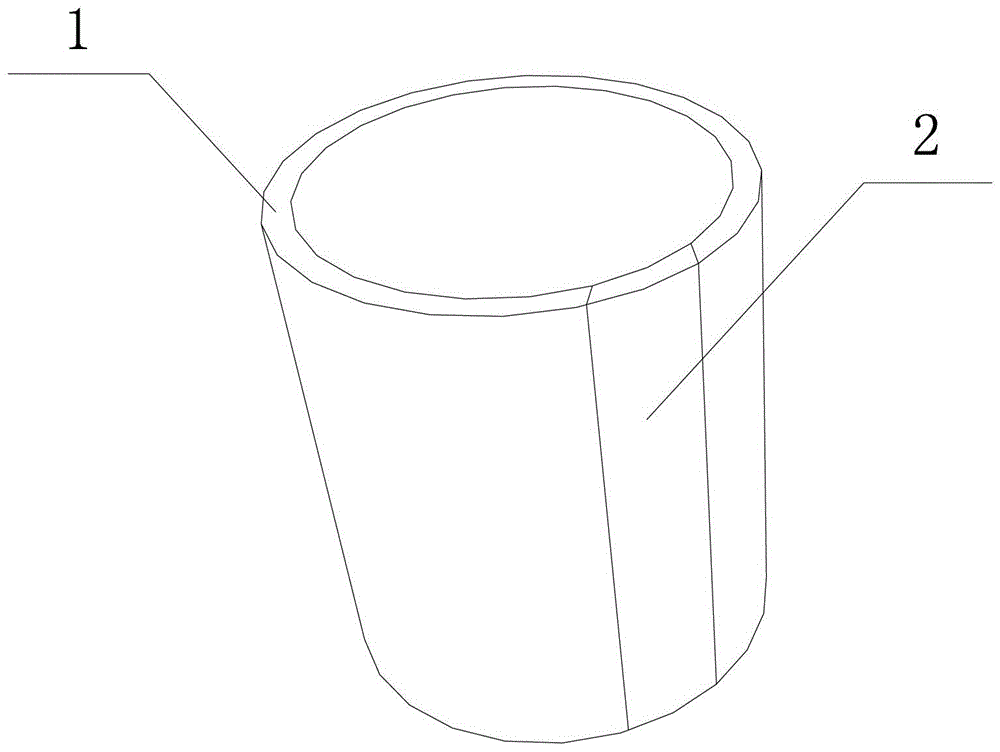

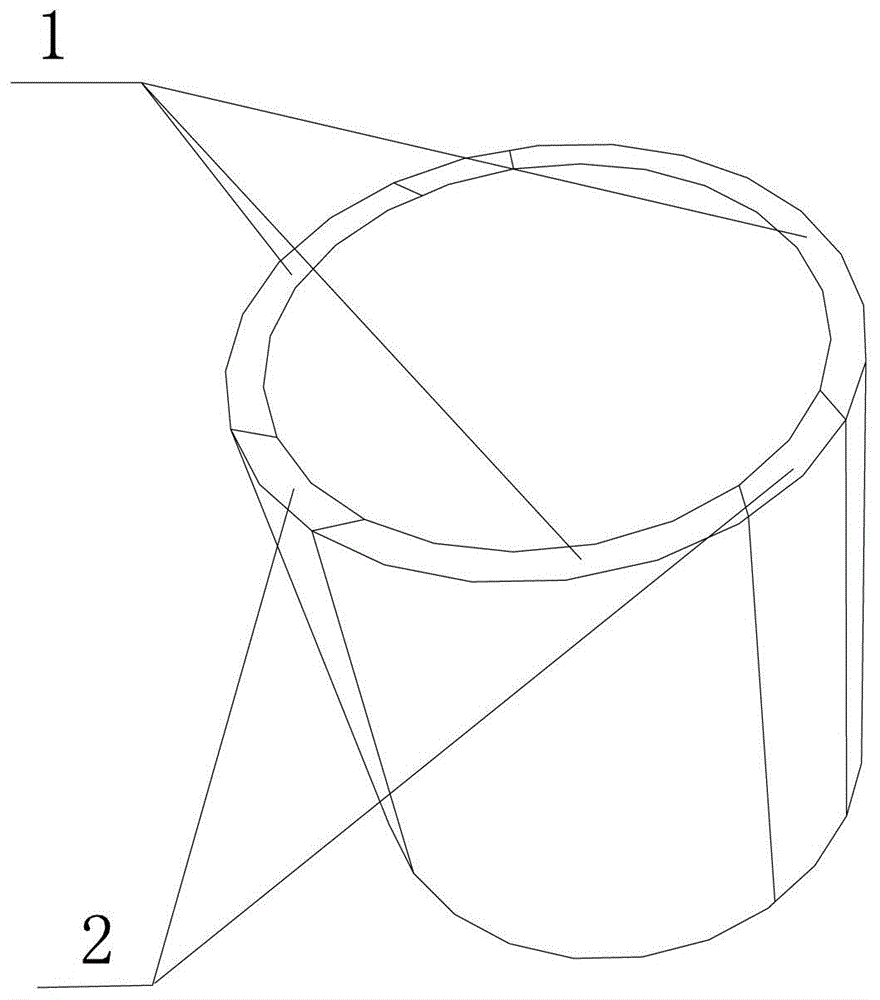

[0014] see figure 1 , figure 2 , a protective sleeve for high-voltage cables, including a metal sleeve 1 and a welded pipe 2; wherein: the side wall of the metal sleeve 1 is provided with a broken seam, the welded pipe 2 is arranged in the broken seam, the welded pipe 2 and the welded pipe 2 The metal sleeves 1 are welded together. One or more broken seams can be set on a metal casing 1, such as figure 1 As mentioned above, a broken seam is provided on a metal casing 1, and there are two schemes during use. The first scheme is to place the welded pipe 2 in an underground groove, and then place the welded pipe 2 in the broken seam After the welding is completed, put the high-voltage cable into the metal casing 1; plan two, first place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com