Xanthan gum non-crosslinking fracturing fluid as well as preparation method and application thereof

A xanthan gum and non-cross-linking technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of fracture conductivity damage, high cost of water-based guar gum fracturing fluid, formation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

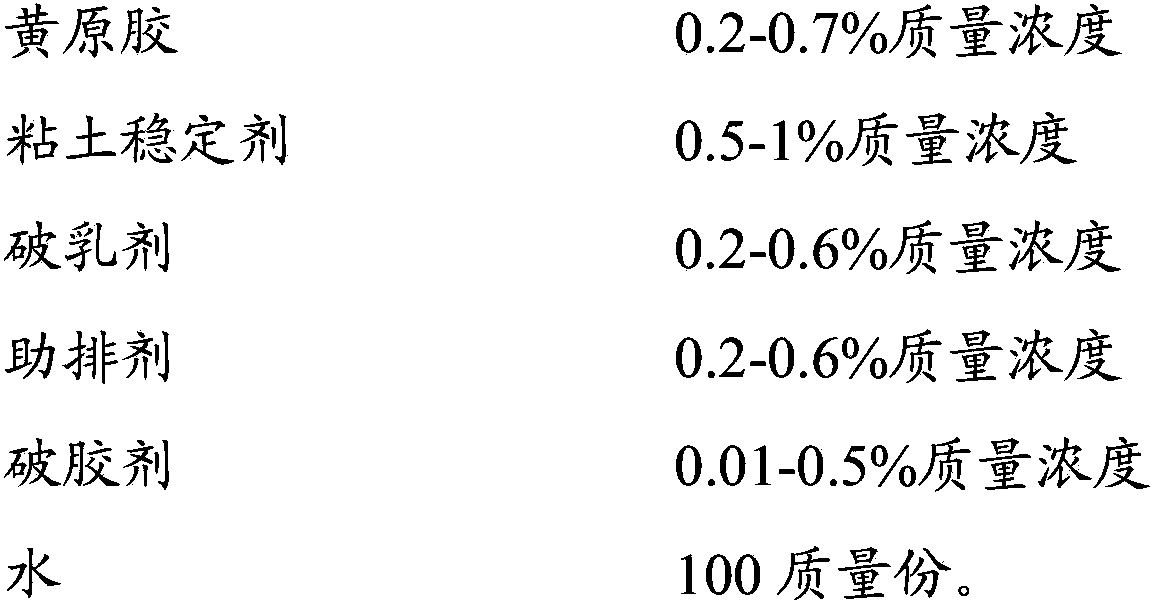

[0034] formula:

[0035]

[0036] Among them, the bactericide is paraformaldehyde; the clay stabilizer is potassium chloride; the demulsifier is OP-10; the drainage aid is a fluorosurfactant compound; the gel breaker is ammonium persulfate; For ferric chloride. Among them, OP-10 is a mixture that is a compound of alkylphenol polyoxyethylene ether.

[0037] Preparation:

[0038] (1) Add xanthan gum, gel breaker and clay stabilizer solid powder of formula quantity in 20 kilowatts dry powder mixing equipment, obtain uniform powder after mixing 8 hours;

[0039] (2) The above powder is formulated into an aqueous solution according to the designed capacity to obtain the first solution;

[0040] (3) The bactericide is prepared as a bactericide solution with a mass concentration of 0.05%, stirred at 900 rpm for 3 hours, and the bactericide solution is added to the solution obtained in step (2) at a speed of 13 milliliters / second In, obtain the second solution;

[0041] (4) Th...

Embodiment 2

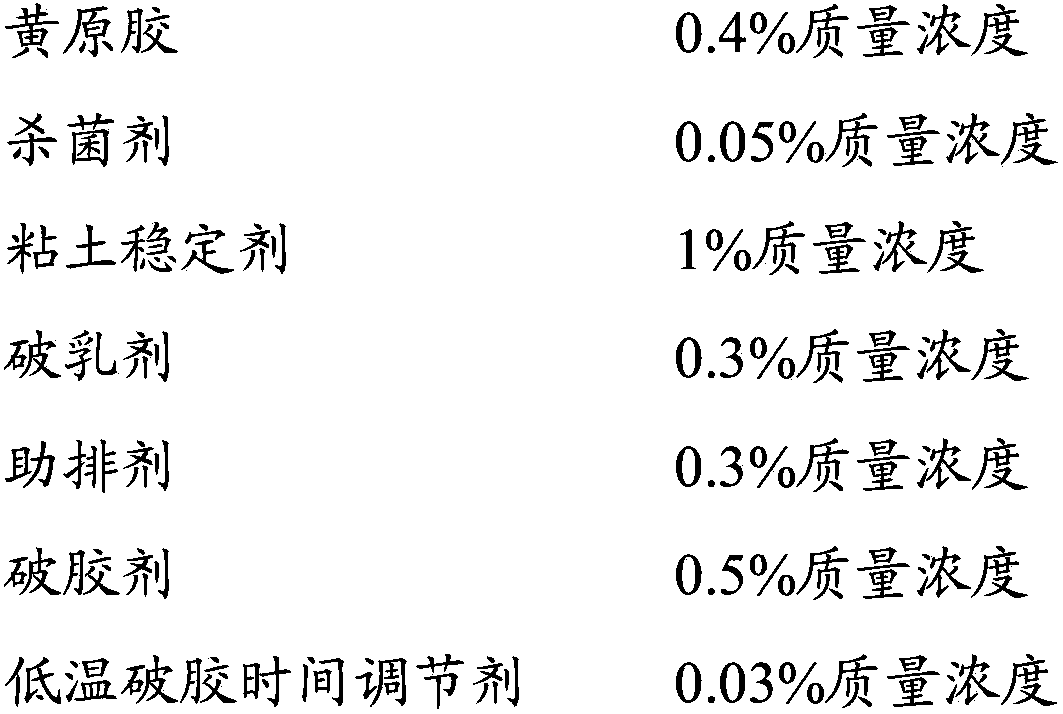

[0047] formula:

[0048]

[0049] Among them, the bactericide is paraformaldehyde; the clay stabilizer is potassium chloride; the demulsifier is OP-10, the drainage aid is a fluorosurfactant compound, and the gel breaker is ammonium persulfate;

[0050] Preparation:

[0051] (1) Add xanthan gum, gel breaker and clay stabilizer solid powder of formula quantity in 20 kilowatts dry powder mixing equipment, obtain uniform powder after mixing 8 hours;

[0052] (2) The above powder is formulated into an aqueous solution according to the designed capacity to obtain the first solution;

[0053] (3) The bactericide is prepared as a 0.1% bactericide solution with a mass concentration, stirred at 900 rpm for 3 hours, and the bactericide solution is added to the solution obtained in step (2) with a speed flow of 13 milliliters / second In, obtain the second solution;

[0054] (4) The demulsifier is prepared as a solution with a mass concentration of 0.5%, and the demulsifier solution is...

Embodiment 3

[0059] formula:

[0060]

[0061] Among them, the bactericide is paraformaldehyde; the clay stabilizer is potassium chloride; the demulsifier is OP-10, the drainage aid is a fluorosurfactant compound, and the gel breaker is ammonium persulfate;

[0062] Preparation:

[0063] (1) Add xanthan gum and gel breaker of formula quantity in 20 kilowatt dry powder mixing equipment, obtain uniform powder after mixing for 8 hours;

[0064] (2) The above powder is formulated into an aqueous solution according to the designed capacity to obtain the first solution;

[0065] (3) The bactericide is prepared as a bactericide solution with a mass concentration of 0.05%, stirred at 900 rpm for 3 hours, and the bactericide solution is added to the solution obtained in step (2) with a speed of 13 milliliters / second In, obtain the second solution;

[0066] (4) The demulsifier is prepared as a solution with a mass concentration of 0.5%, and the demulsifier solution is added to the second solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com