Sterilization method for pet food raw materials

A pet food and raw material technology, applied in the direction of chemistry, can solve the problems of wasting energy, increasing costs, destroying the taste of pet food, etc., and achieving the effect of reducing costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

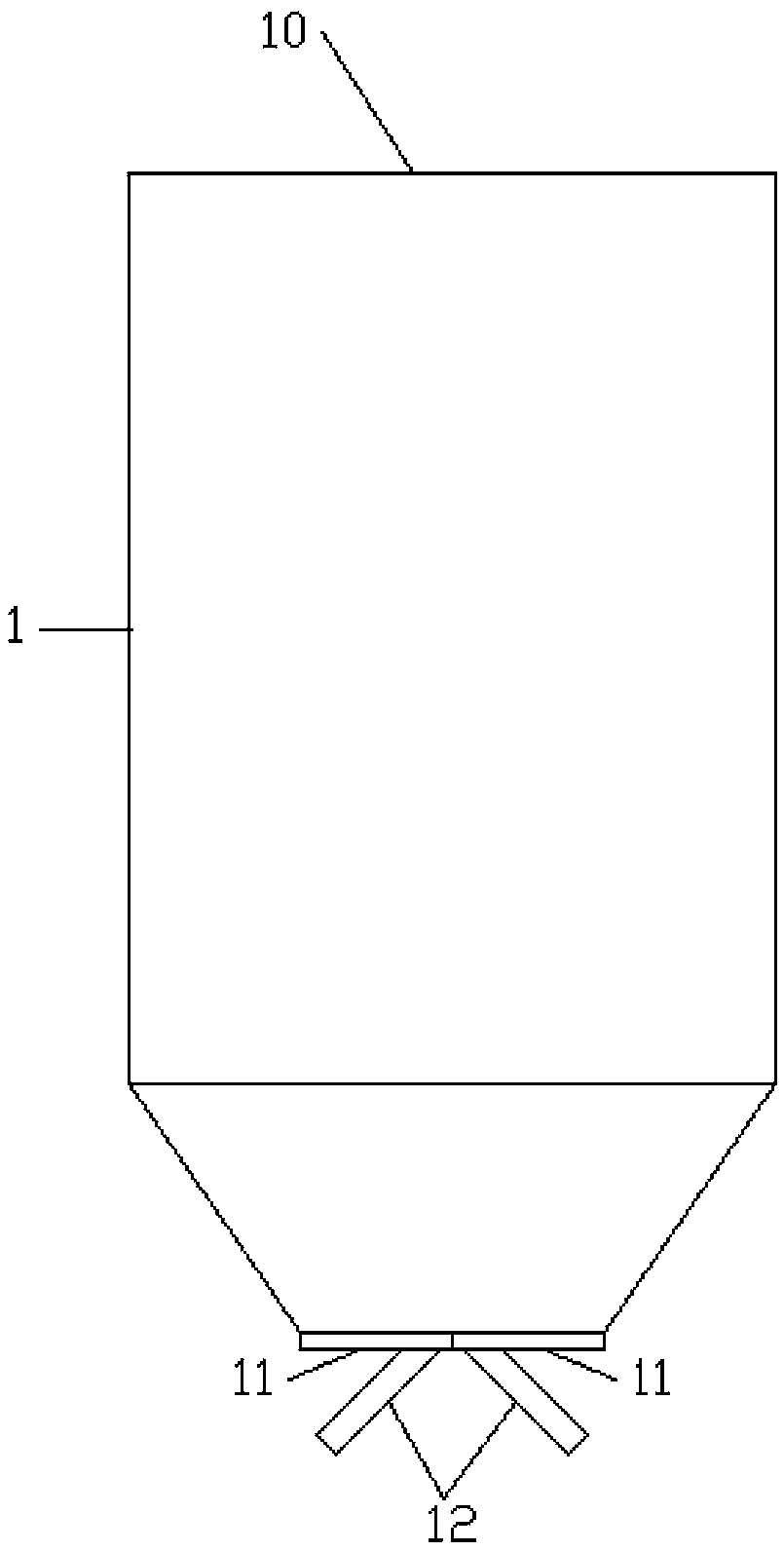

[0010] Combine below figure 1 Specifically illustrate the reaction kettle 1 for sterilizing pet food raw materials, the top of the reaction kettle is provided with a feed inlet 10, the inverted conical bottom of the reaction kettle is provided with a discharge opening, and the discharge opening is provided with a discharge door 11. An ozone diffuser is arranged inside, and the ozone diffuser is connected with an ozone source. The blanking door is two semicircular side-by-side doors hinged on the reactor, and the blanking door is opened and closed by a cylinder 12 . The ozone dispersing device includes a gas pipe spirally arranged on the inner wall of the bottom of the reaction kettle, and the gas dispersing hole is arranged on the gas pipe.

[0011] The pet food raw material sterilization method is as follows: the pet food raw material is put into the reactor through the feeding port, and then the ozone diffuser injects ozone into the reactor for sterilization, and the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com