Cutting torch initial positioning device

An initial positioning and cutting torch technology, applied in welding equipment, metal processing equipment, plasma welding equipment, etc., can solve the problems of black screen of height controller, high frequency interference, and no anti-collision device, so as to avoid black screen and interference , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical solution of the present invention more specifically, the present invention will be further elaborated below in conjunction with the accompanying drawings, but the present invention is not limited to the scope described in the specific embodiments.

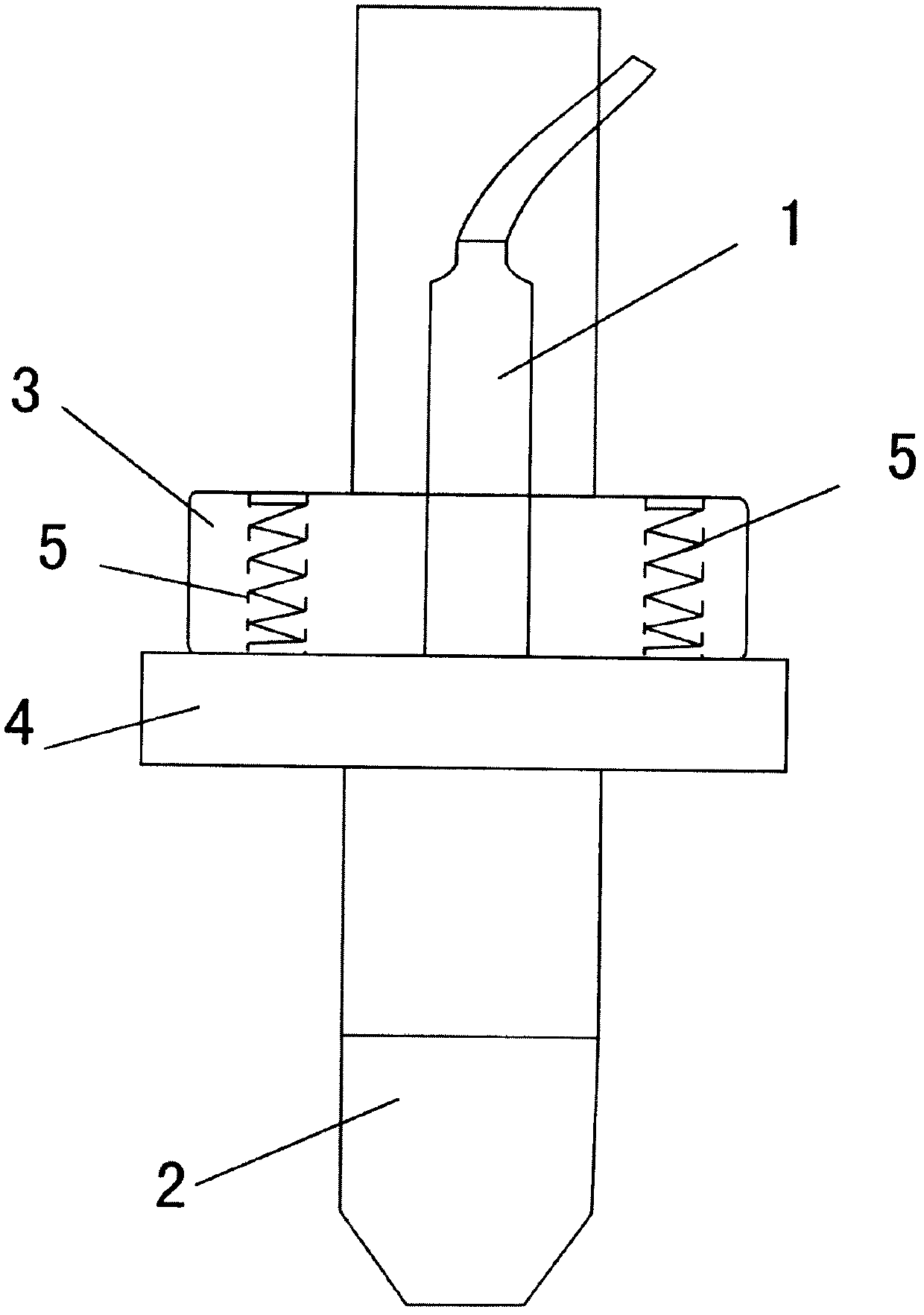

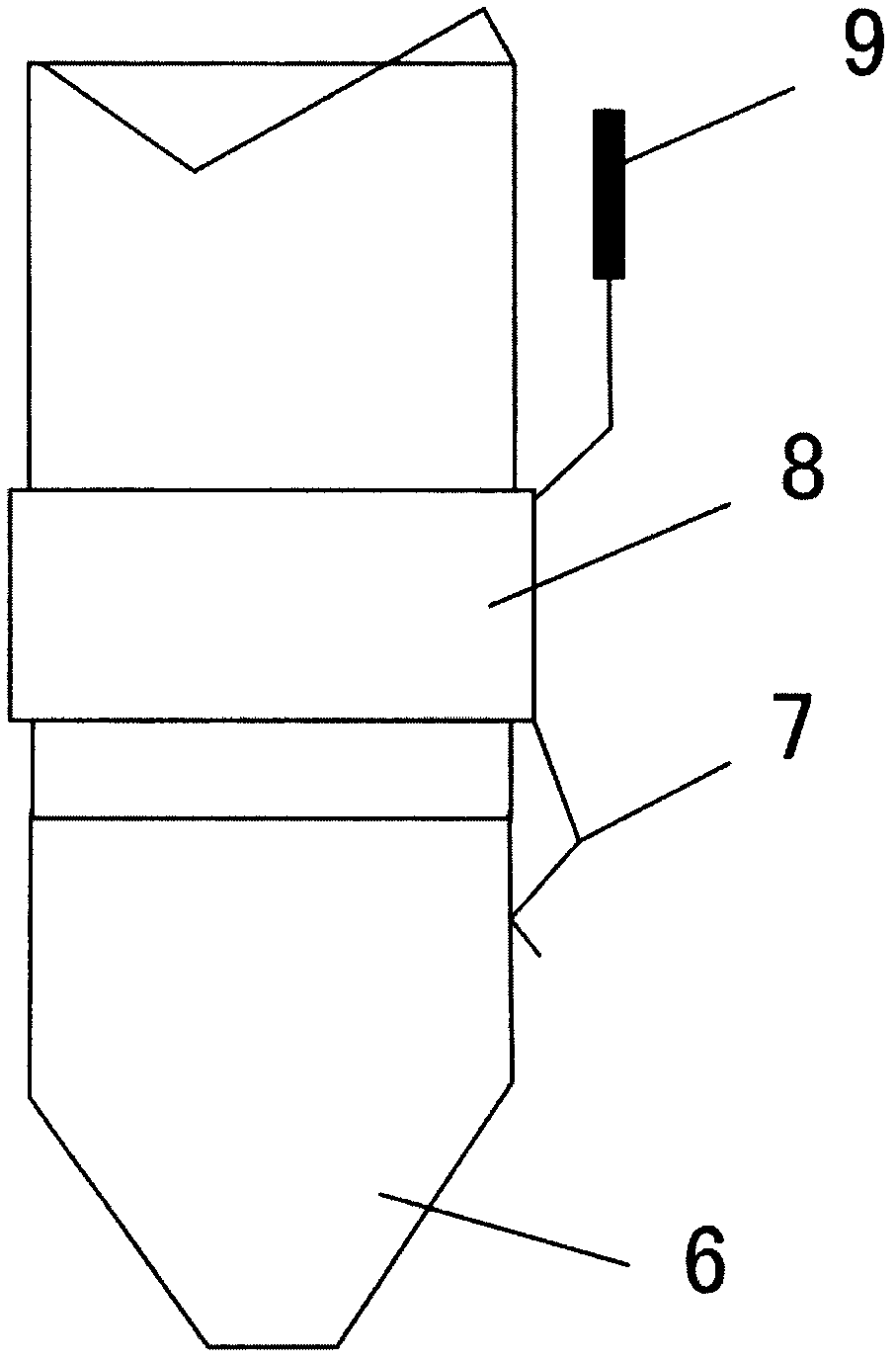

[0021] to combine figure 1 , the cutting torch automatic initial positioning device provided by the present invention includes a cutting torch 2 and a height regulator, and also includes a positioning torch fixture and a proximity switch 1, and the proximity switch 1 is fixed on the cutting torch 2 through the positioning torch fixture Above, the positioning torch fixture includes a fixture top seat 3 and a fixture base 4. An elastic member 5 is installed between the fixture top seat 3 and the fixture base 4. The elastic member 5 is a spring. The fixture top seat 3 is fixed to the positioning torch fixture, and the fixture There is a certain gap between the base 4 and the cutting torch 2, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap