Bulletproof and anti-smashing composite glass and its manufacturing method

A technology of composite glass, manufacturing method, applied in the direction of chemical instrument and method, lamination device, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

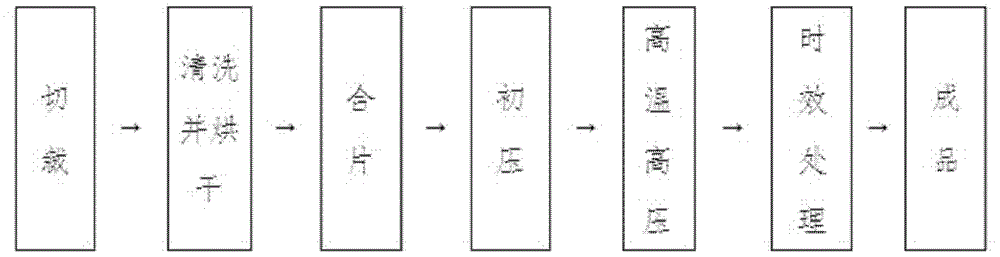

[0022] Selected raw material configuration: 8mm white glass + 1.14mm PVB film + 8mm white glass + 1.14mm PVB film + 8mm white glass + 1.14mm PVB film + 5mm white glass, the white glass adopts high-quality float method with low iron content and good flexibility Glass is used as the original film. PVB film (polyvinyl butyral) is made of imported high-quality PVB anti-tear film (DuPont or Solutia). The production steps are:

[0023] 1) Cut glass and PVB film;

[0024] 2) Clean and dry the glass;

[0025] 3) Combine glass and PVB film;

[0026] 4) Carry out the initial pressure, the initial pressure temperature is adjusted to 215°C, and the initial pressure is 0.6MPa;

[0027] 5) Carry out high temperature and high pressure in the autoclave, the inflation temperature remains unchanged at 40°C, the equilibrium temperature is 140°C, the equilibrium pressure is 1.25MPa, the equilibrium time is 60 minutes, the exhaust temperature is 40°C, and the cooling time of the glass in the aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com