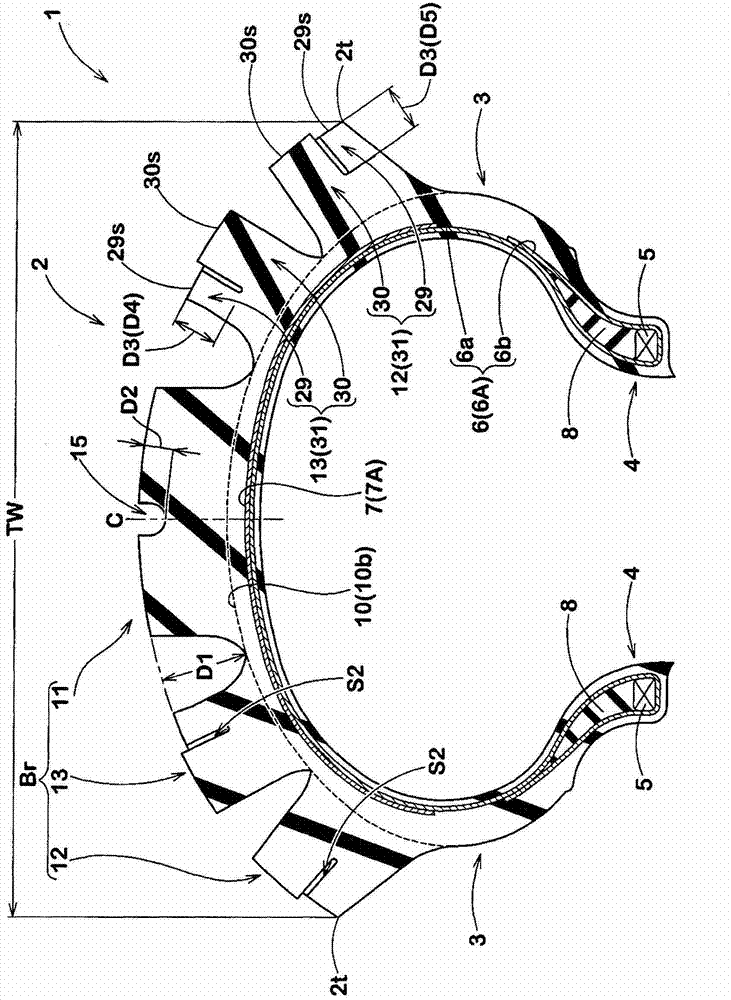

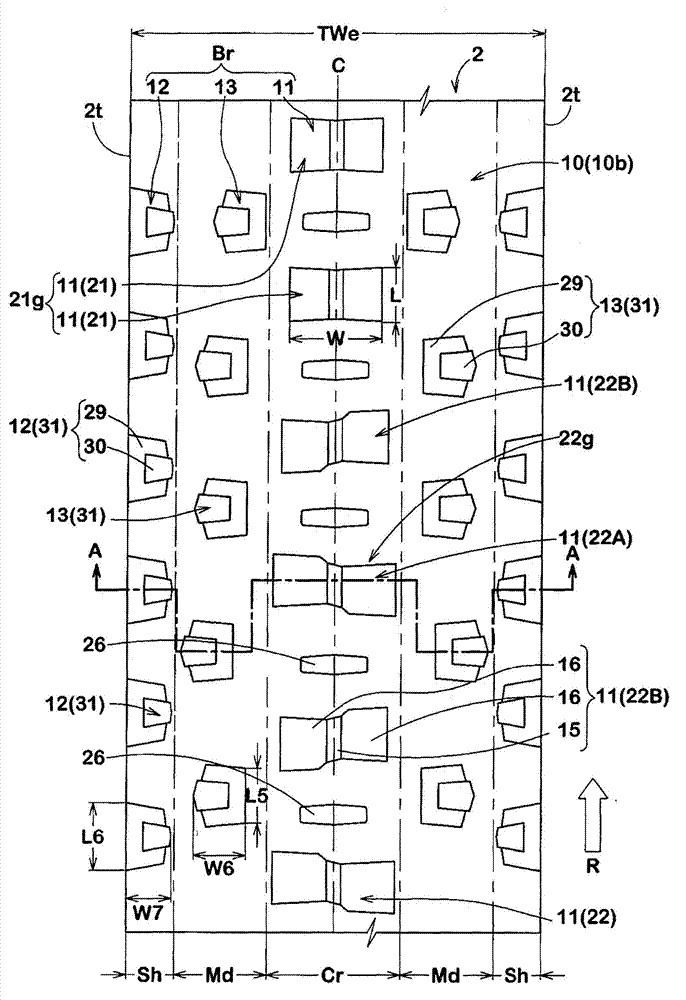

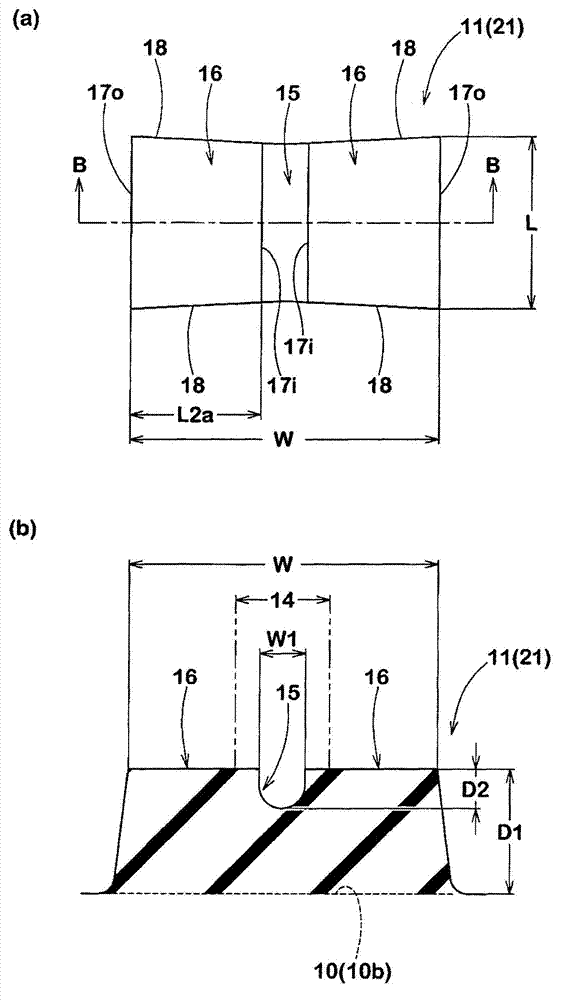

Pneumatic tire for running on rough terrain

A technology for inflating tires and ground, applied to motorcycle tires, off-road vehicle tires, tire parts, etc., to achieve the effect of improving handling stability and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Manufacturing has figure 1 The motorcycle tires for running on rough terrain having the basic structure shown in Table 1 and having shifted blocks shown in Table 1, and their performances were evaluated. In addition, for comparison, Comparative Examples 1 to 3 were also evaluated in the same manner. Comparative Example 1 is a conventional tire having no shifted blocks and notched blocks. In addition, Comparative Example 2 is a tire in which shifted blocks are arranged as crown blocks, and conventional blocks having no grooves are arranged in the middle blocks and shoulder blocks. In addition, Comparative Example 3 is a tire in which notched blocks are arranged as middle blocks and shoulder blocks, and conventional blocks having no slits are arranged as crown blocks. In addition, the common specifications of each tire are as follows.

[0101] Vehicle used: Displacement 450cc motorcycle

[0102] Tire size:

[0103] Front wheel: 90 / 100-21

[0104] Rear wheel: 120 / 80-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com