Implementation method for low voltage conductive heating floor heating system

A low-voltage, floor-to-floor technology, applied in the field of conductive heating floor heating, can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

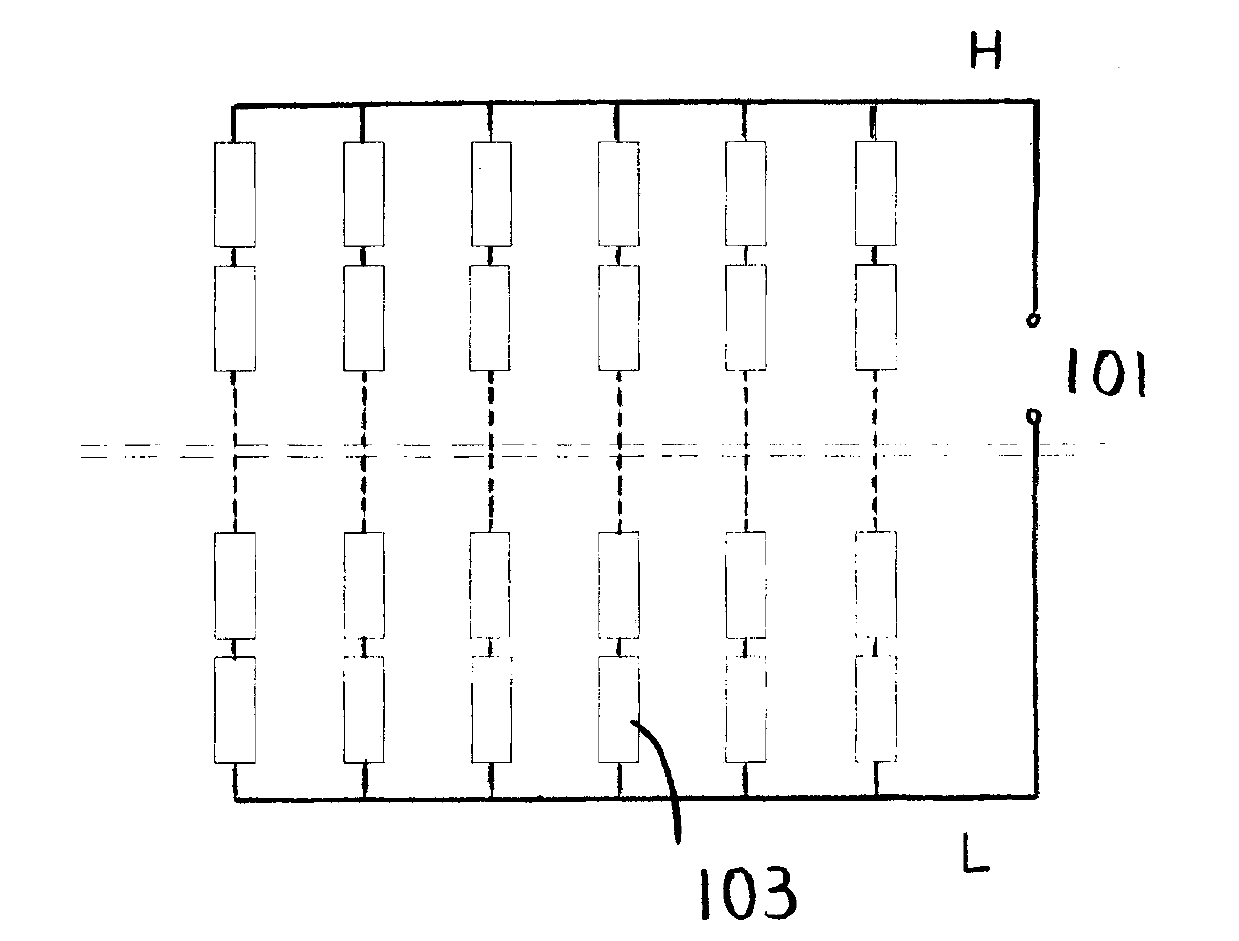

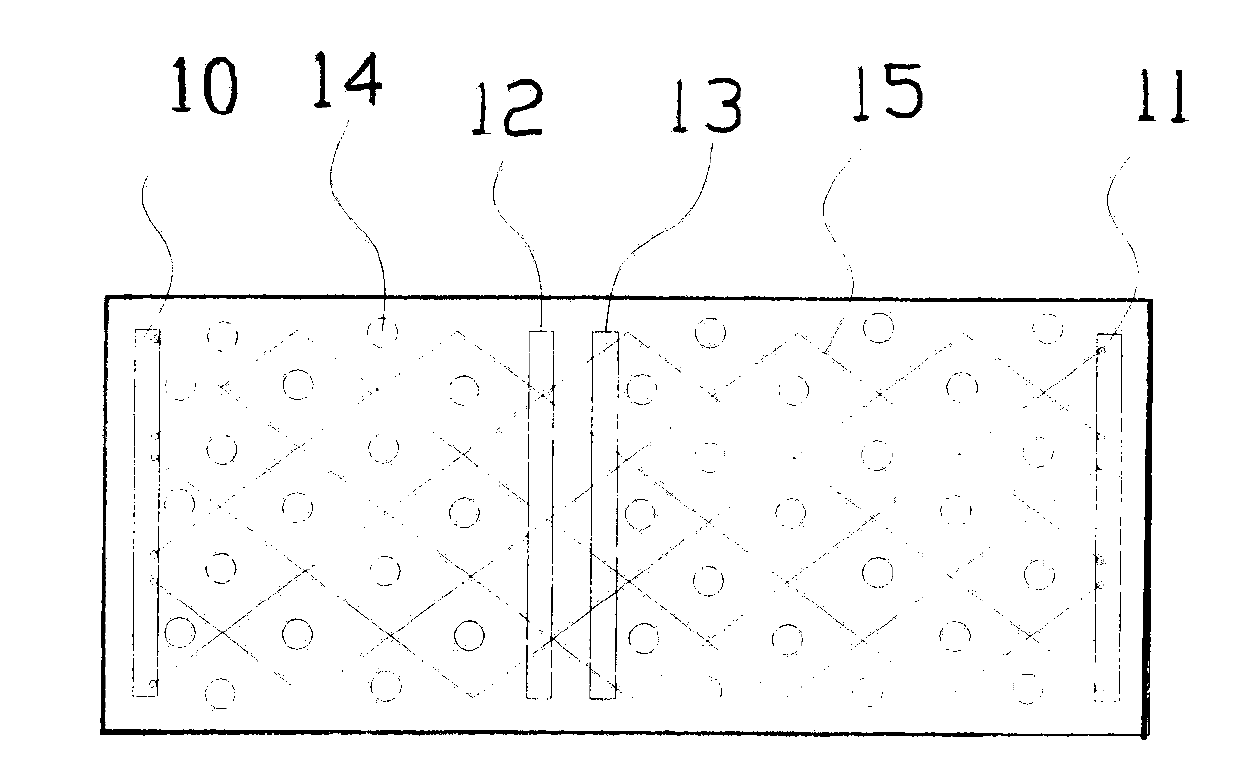

[0019] According to the technical method of the present invention, a low-voltage conductive heating floor system is realized, which consists of three parts: a household power input terminal, a main lead terminal and a conductive heating floor system. There is a voltage equivalent to the household voltage value at the input terminal of the household power supply and the main wire terminal. The voltage source of the conductive heating floor plate is close to or even lower than the safe voltage value of the human body through the method of series voltage division in the conductive heating floor unit, which is extremely Great security.

[0020] figure 1 It is a schematic structural diagram of the working principle of the low-voltage conductive heating floor in the specific embodiment of the present inv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap