Planar suspension bearing

A floating bearing and plane technology, applied in the field of bearings, can solve the problems of relatively high accuracy requirements of pressure sensors, inaccurate detection methods, unstable detection results, etc., to achieve the effect of improving detection accuracy and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

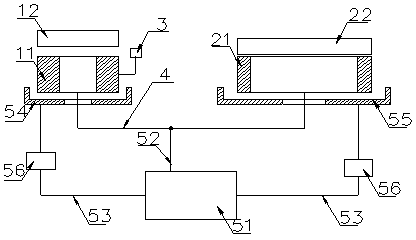

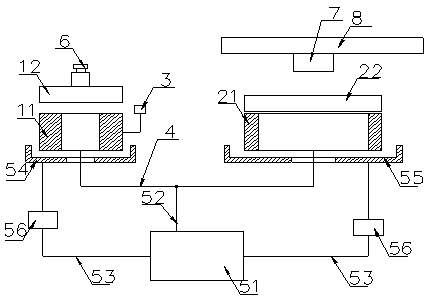

[0019] See figure 1 with figure 2 , As shown in the legend: a flat suspension bearing, used to detect the accuracy of the pressure sensor 7, including a small suspension bearing, a large suspension bearing, a communication pipe 4 and an oil supplement device, the small suspension bearing It includes a small container 11, a displacement sensor 3, and a small movable support 12; the large suspension bearing includes a large container and a large movable support 22; the oil supplement device includes an oil tank 51 and an oil upper pipe 52; The displacement sensor 3 is respectively arranged on the small movable support 12 and the large movable support 22; the small movable support 12 and the large movable support 22 are respectively arranged above the small container 11 and the large container 21 The small container 11 and the large container 21 are open at the upper end; the bottom of the small container 11 and the large container 21 are connected by the communicating pipe 4; the...

Embodiment 2

[0029] The rest is the same as the embodiment 1, except that the pressure area of the small container and the large container is in a ratio of 1:50.

Embodiment 3

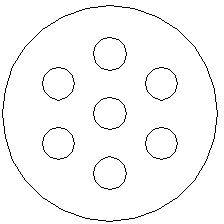

[0031] The rest is the same as the first embodiment, the difference is that the pressure surfaces of the small container and the large container are both combined pressure surfaces including nine pressure surfaces.

[0032] The beneficial effects of using the above technical solutions are: first, due to the principle of the communicating device, the accuracy of the pressure sensor can be detected by weight; second, the pressure area of the small container and the large container becomes a certain The ratio of the pressure sensor can be enlarged to improve the detection accuracy; third, because the pressure surface of the small container and the large container is a combination of multiple pressure surfaces, they are distributed on the small movable support and the large The pressure on the movable support is more uniform; fourth, the oil supplement device can be used to keep the pressure at a constant value; fifth, because the oil return device is used, the oil overflowing from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com