Multi-stage fisher with dimension unknown inner pipe

An overshot and size technology, applied in wellbore/well components, earthwork drilling, etc., can solve problems such as delaying drilling time, delaying oil and gas exploration progress, etc., and achieve the effect of reducing labor intensity, simple structure, and speeding up progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

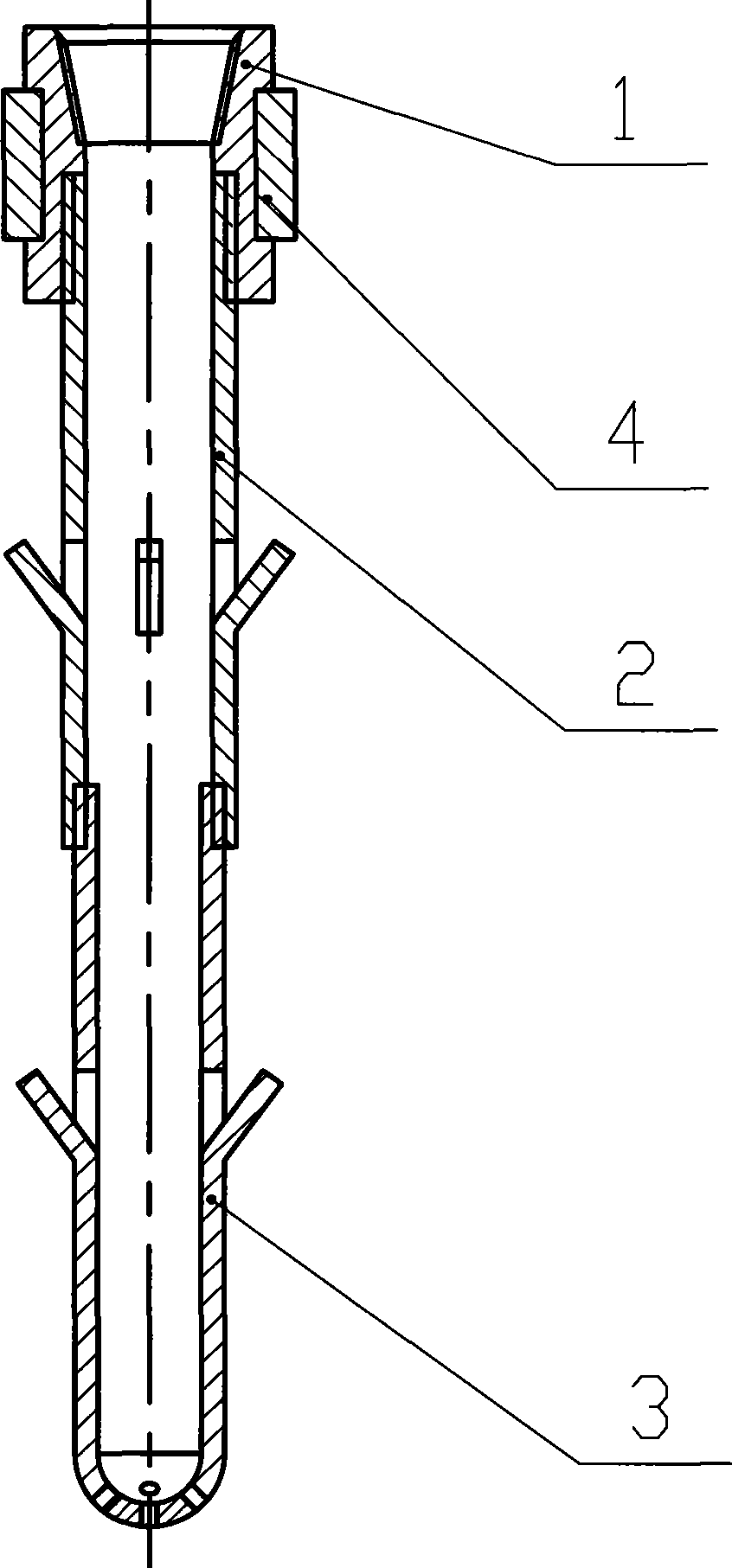

[0010] like figure 1 As shown, a multi-stage overshot with an unknown inner tube size is mainly composed of a drill tool joint 1, a first-level outer-opening window clamping body 2, a second-level outward-opening window clamping body 3, and a drilling tool joint centralizing block 4.

[0011] The drilling tool joint 1 is connected with the first-level outward opening window clamping body 2 with threads, the first-level outward opening window clamping body 2 and the second-level outward opening window clamping body 3 are also connected with threaded screws, and the drilling tool joint centralizing block 4 Mounted on drill joints.

[0012] Because there is a centralizing block on the tool joint 1, the lower part of the clamping body 3 of the second-stage outward opening window is in a streamlined shape. , the streamlined outside-opening window clamp body 3 is very easy to straighten and enter the falling objects, and the clamps on the outward-opening window clamp body 3 are squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com