Built-in sunshade hollow glass product test device

A sun-shading hollow glass and test device technology, applied in the direction of material inspection products, etc., can solve the problems of long test period, inconvenient simulation test, low force measurement accuracy, etc., and achieve the effect of short test period, high force measurement accuracy and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

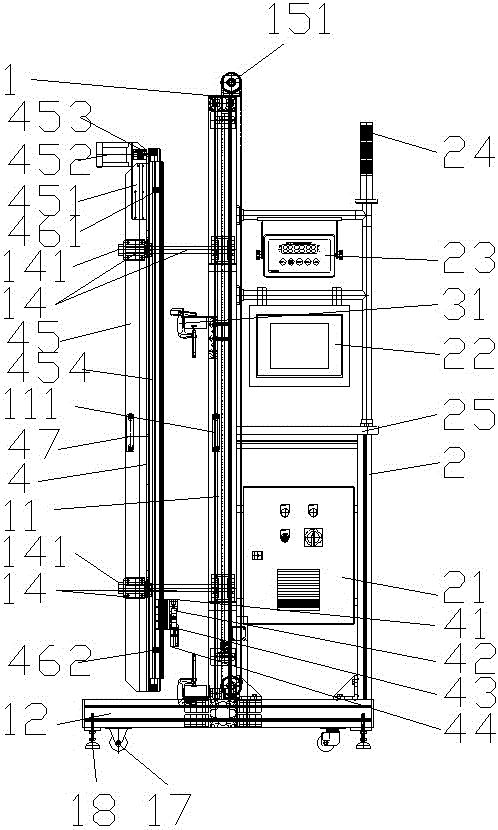

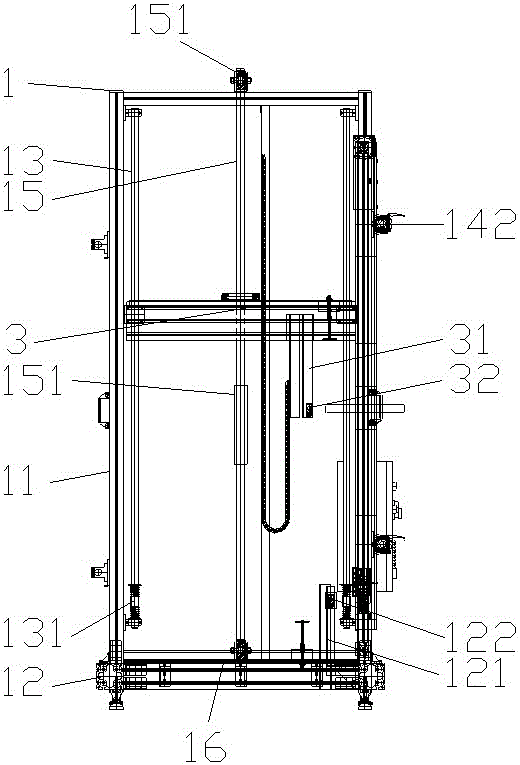

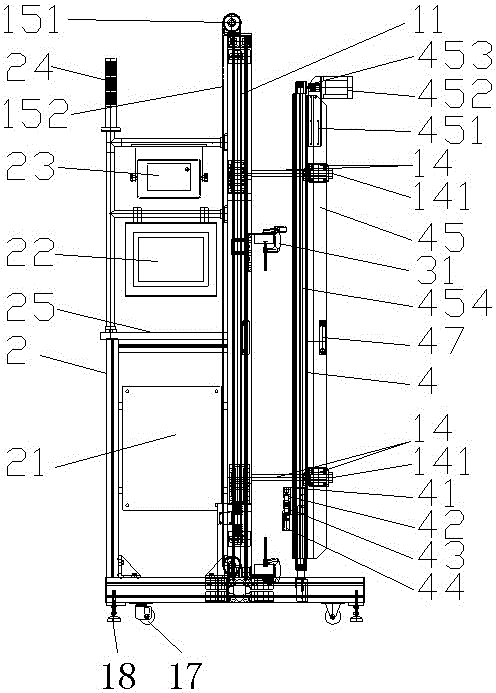

[0025] figure 1 It is the front view of the built-in sunshade hollow glass product testing device of the present invention, figure 2 It is the left view of the built-in sunshade hollow glass product testing device of the present invention, image 3 It is the rear view of the built-in sunshade hollow glass product testing device of the present invention, Figure 4 For the top view of the built-in sunshade hollow glass product testing device of the present invention, please refer to Figure 1 to Figure 4 shown. The built-in sunshade hollow glass product testing device of the present invention includes a main frame 1, which includes a rectangular longitudinal frame 11 and two transverse bars 12, and the two transverse bars 12 are respectively arranged at the bottom of the longitudinal frame 11. One side of a transverse bar 12 is provided with a testing machine frame 2 near the longitudinal frame 11. This testing machine frame 2 is a rectangular longitudinal frame. An electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com