Stator for rotating electrical machine, and method for producing same

A technology for rotating electrical machines and stators, which is applied to electromechanical devices, electrical components, electrical components, etc., and can solve problems such as short-circuit accidents of stator coils and insufficient insulation of stator cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

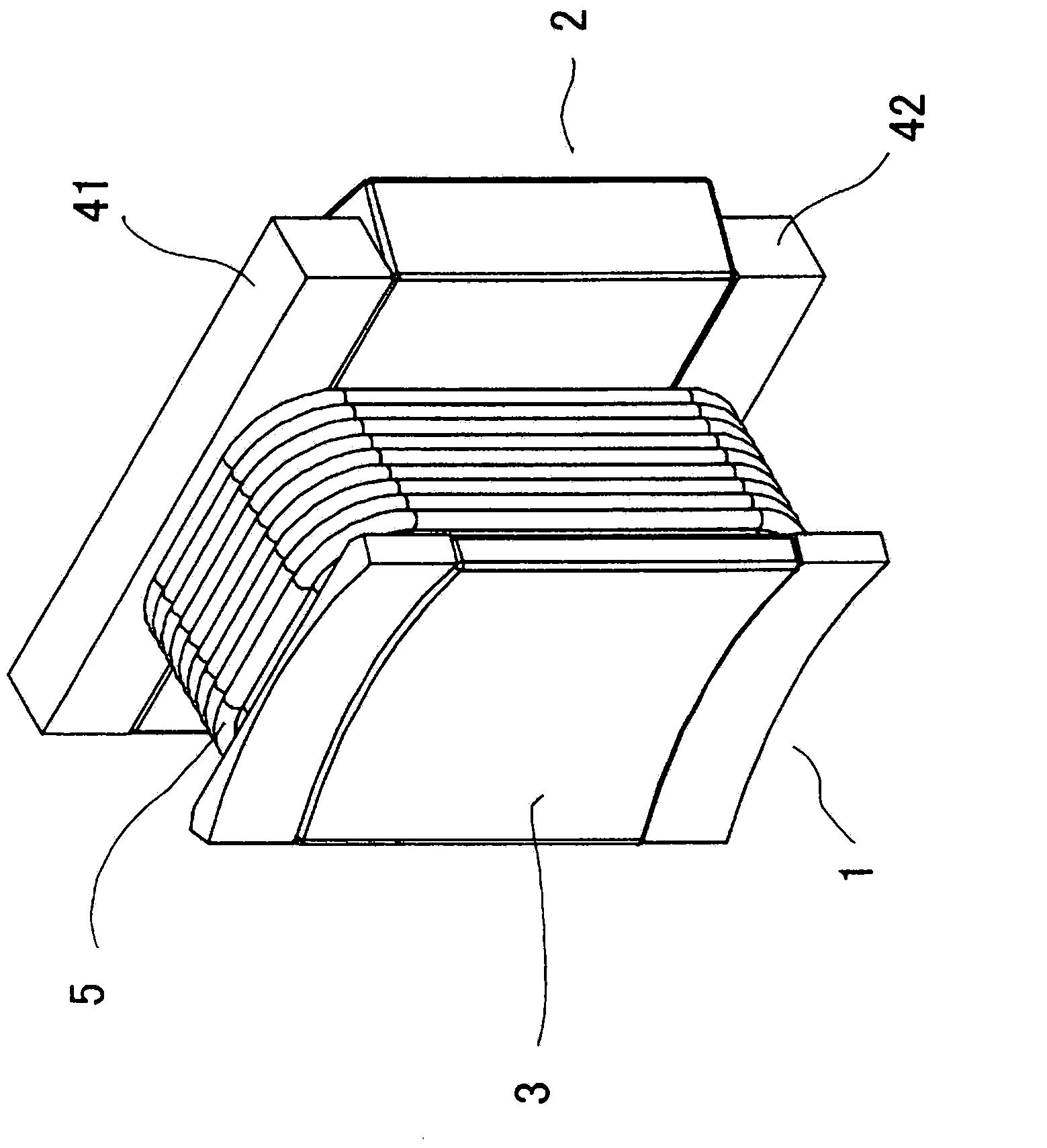

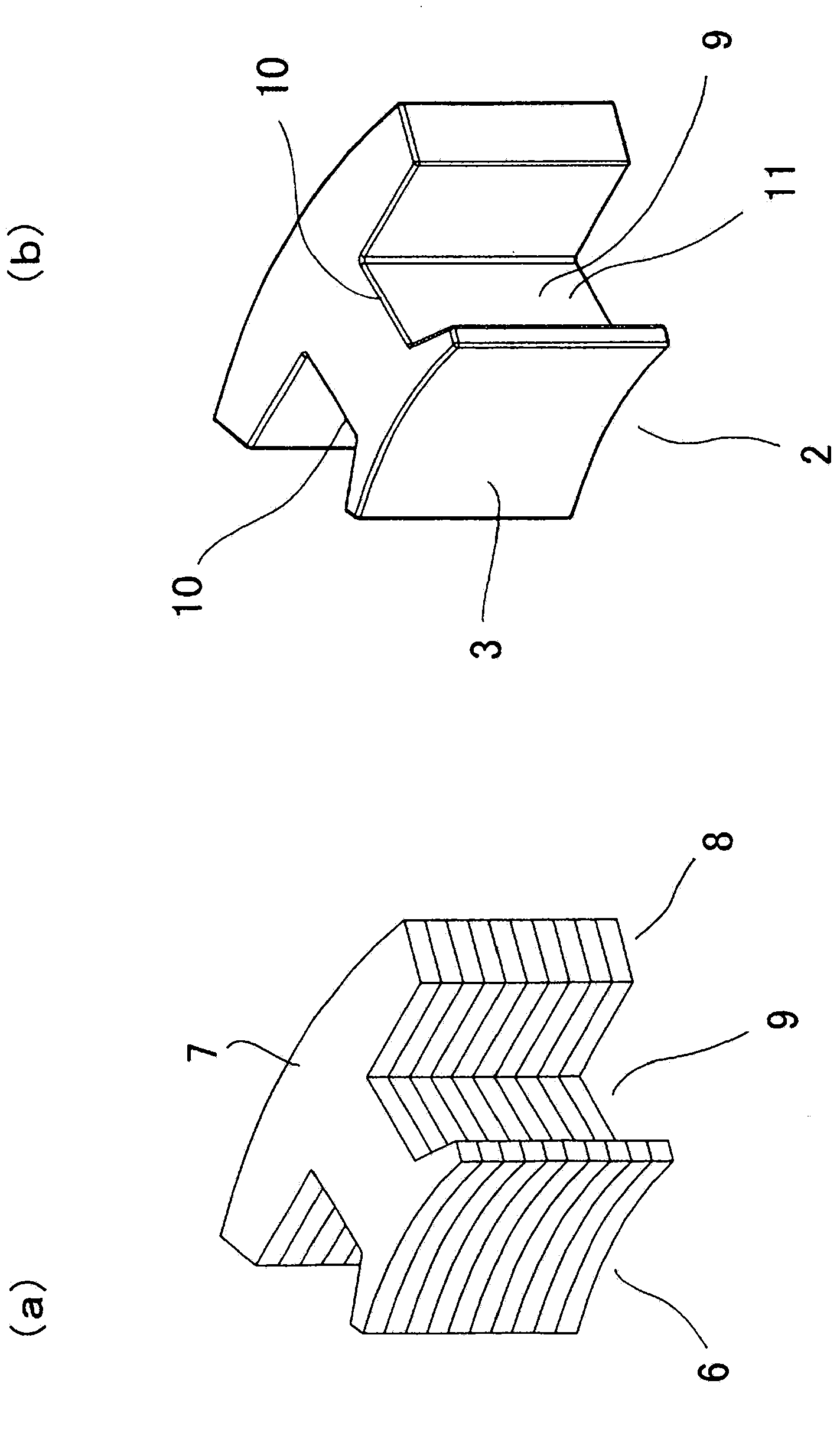

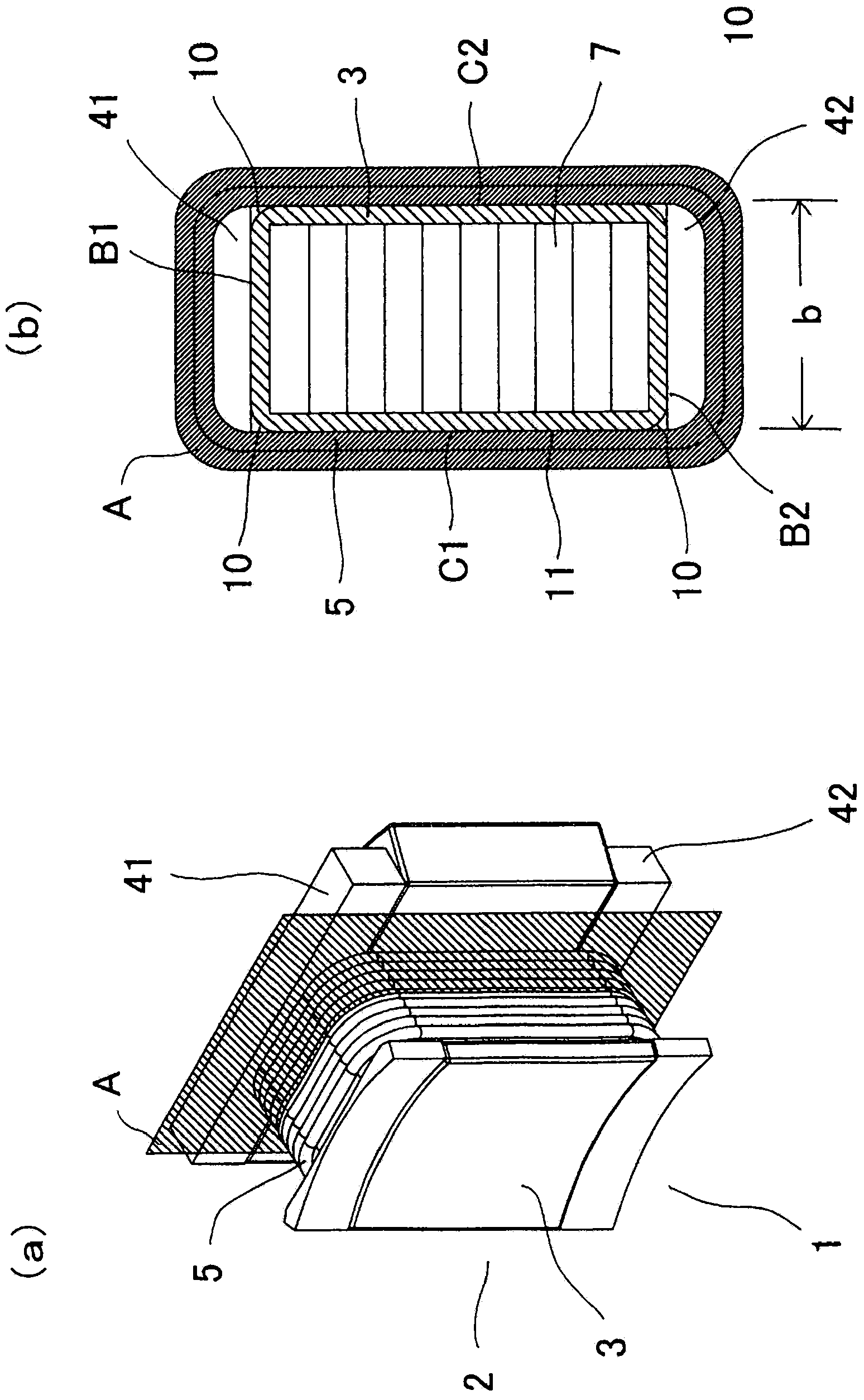

[0038] figure 1 It is a perspective view showing the stator magnetic pole portion in the stator of the rotating electrical machine according to Embodiment 1 of the present invention. figure 1Among them, the stator magnetic pole portion 1 constituting the stator of a rotating electric machine such as a motor includes a stator core 2 having a coating film 3 formed by applying an insulating paint coating process on the surface of a laminated core material. The core sheet laminate is formed by stacking a plurality of core sheets made of metal; the first bobbin 41 made of an insulator is mounted on one end surface of the stator core 2 which is the first surface in the stacking direction of the core sheets; a second bobbin 42 made of an insulating material, which is fitted on the other end face of the stator core 2 which is the second face in the stacking direction of the core sheets; and through the first bobbin 41 and the second bobbin 42 The stator coil 5 is formed by winding a ...

Embodiment approach 2

[0059] Figure 7 It is a perspective view showing the stator magnetic pole portion in the stator of the rotating electric machine according to Embodiment 2 of the present invention. Figure 7 Among them, a stator magnetic pole portion 1 a constituting a stator of a rotating electric machine such as a motor includes a stator core 2 a and a stator coil 5 assembled by winding a conductive wire around a tooth portion 9 a of the stator core 2 a. The stator core 2a is equipped with a first bobbin 42a and a second bobbin 42a respectively at both ends of a chip sheet laminate 6a formed by laminating a predetermined number of chip sheets. The core sheet laminate 6a, the first bobbin 42a, and the second bobbin 42a are integrally coated with insulating paint to form the stator core 16a. The stator coil 5 is formed by winding conductive wires around the tooth portions 9a of the stator core 2a configured in this way.

[0060]In addition, the first bobbin 41 and the second bobbin 42 may b...

Embodiment approach 3

[0071] Figure 10 is a perspective view showing a core sheet in a stator of a rotating electrical machine according to Embodiment 3 of the present invention, Figure 11 It is a perspective view showing the stator magnetic poles in the stator of the rotating electric machine according to Embodiment 3 of the present invention. In the aforementioned first embodiment, the stator core stack 6 is constituted by using the substantially T-shaped core material 7 having the yoke 8 and the teeth 9 protruding from the yoke 8. However, in the third embodiment, as Figure 10 As shown, the stator core laminated body 6b may be constituted by using a core sheet 7b having a plurality of yoke portions 8b connected via bent portions 17 and a plurality of teeth portions 9b protruding substantially perpendicularly from each yoke portion 8b.

[0072] Such as Figure 11 As shown, the stator core 2b is produced by applying a coating film 3b made of insulating paint to the entire surface of a core sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com