Assembling method of clutch anti-lock drive disk

An assembly method and technology for driving discs, which are applied to clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of low connection strength, high energy consumption of welding equipment, not enough economical and environmental protection, etc., and achieve high connection strength and connection strength. Stable and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

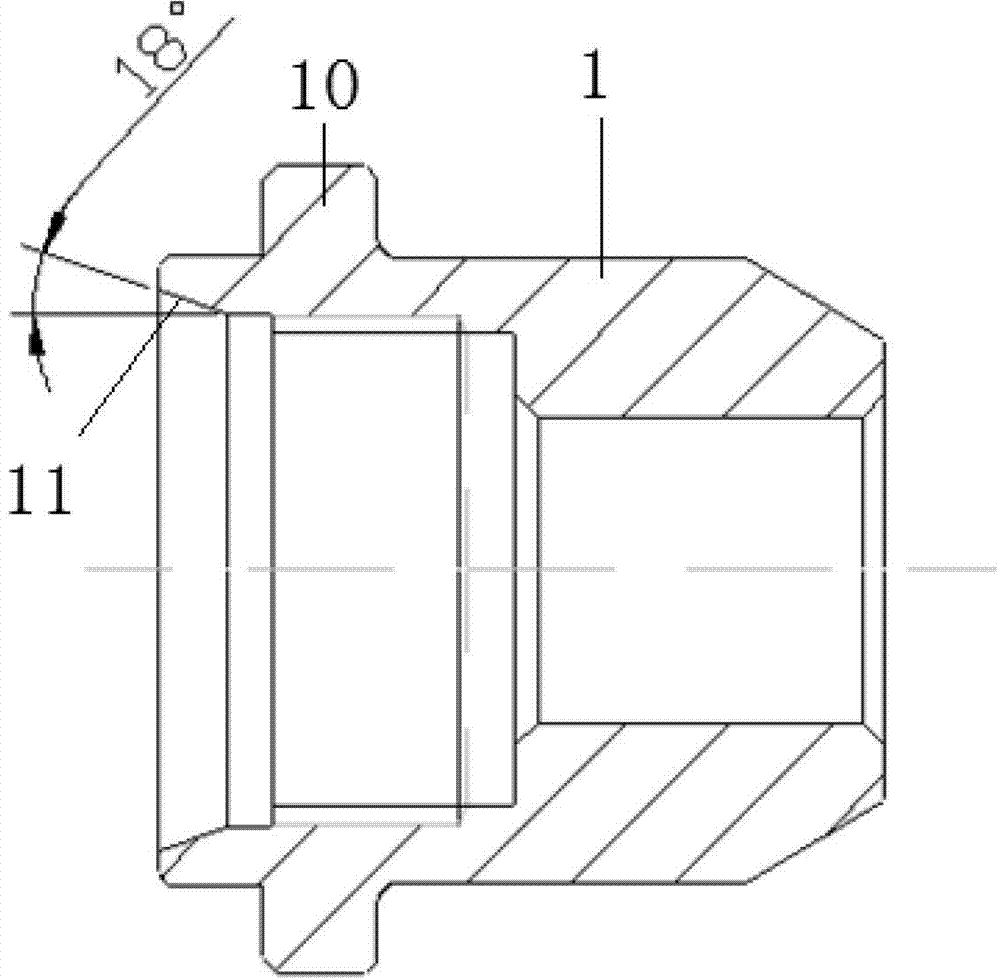

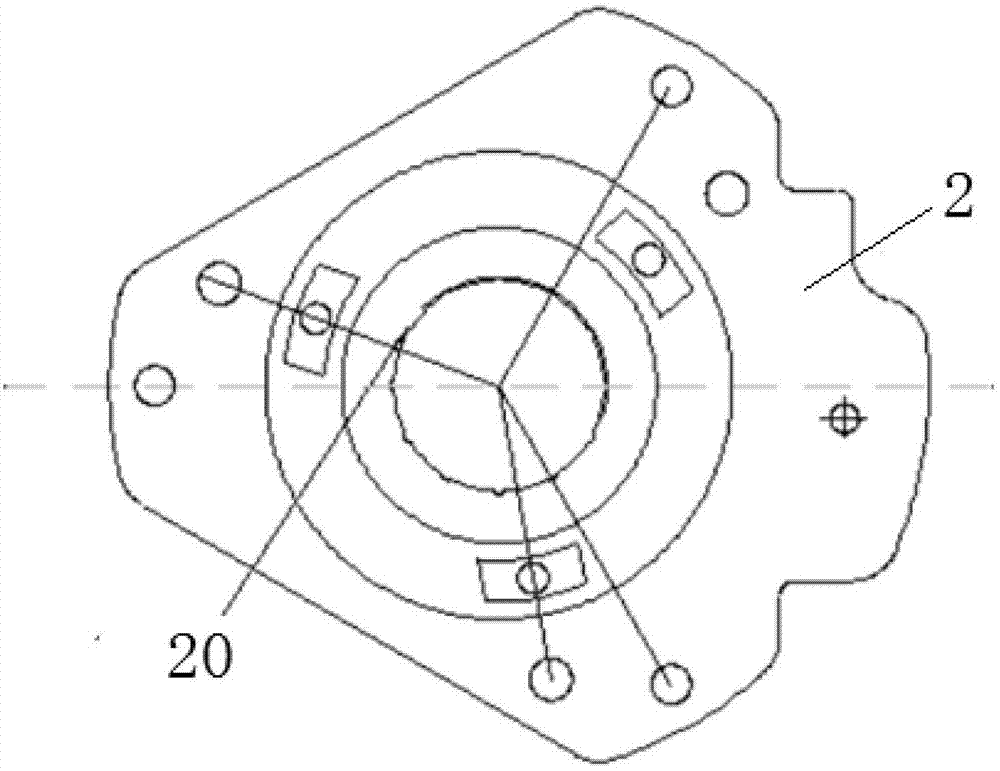

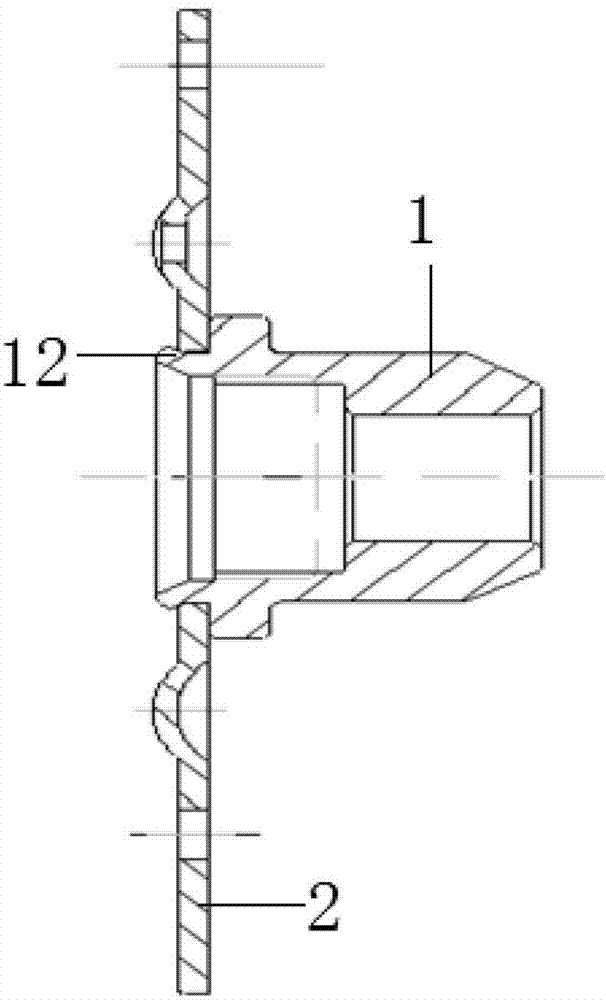

[0017] Combine below Figure 1 to Figure 4 The anti-lock drive disc of the present invention will be described in detail. It includes a hub shaft 1 with a central hole and a driving piece 2 with a connecting hole. An annular flange 10 is provided on the outer circumference of the front end of the hub shaft 1. The driving piece 2 is sleeved on the hub shaft 1 through the connecting hole. The front end and the rear end surface abut against the front end surface of the annular flange 10 , and the driving piece 2 is fastened to the front end of the hub axle 1 through the riveting structure 12 . The riveting structure 12 includes a tooth shape 20 arranged around the inner circumference of the connecting hole of the driving piece, preferably at 12 points. The front end of the center hole of the hub shaft is provided with an 18° chamfer 11 . The rear end of the hub shaft 1 is sleeved with a suction piece 3 , and the suction piece 3 is fastened to the driving piece 2 by a rivet 30 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com