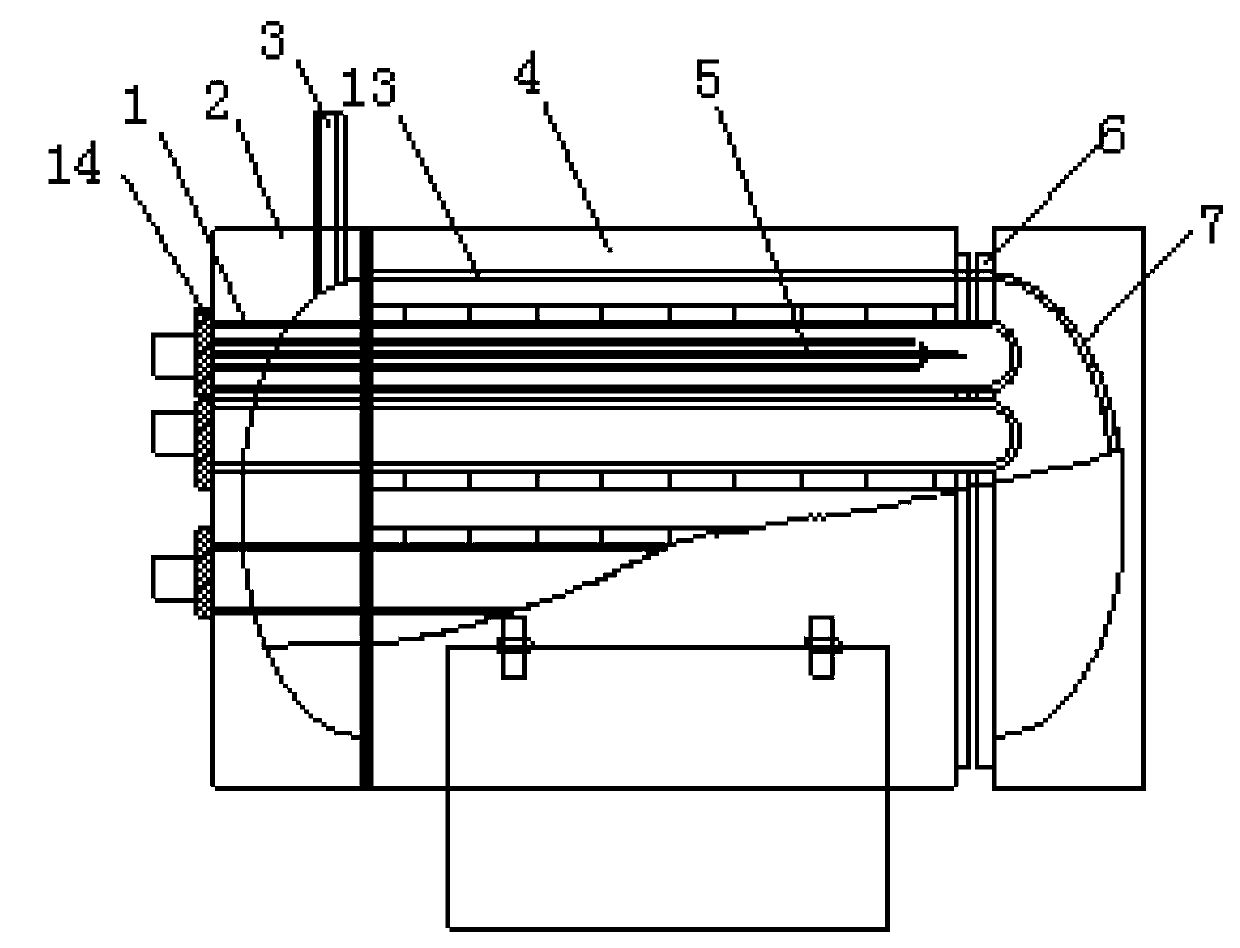

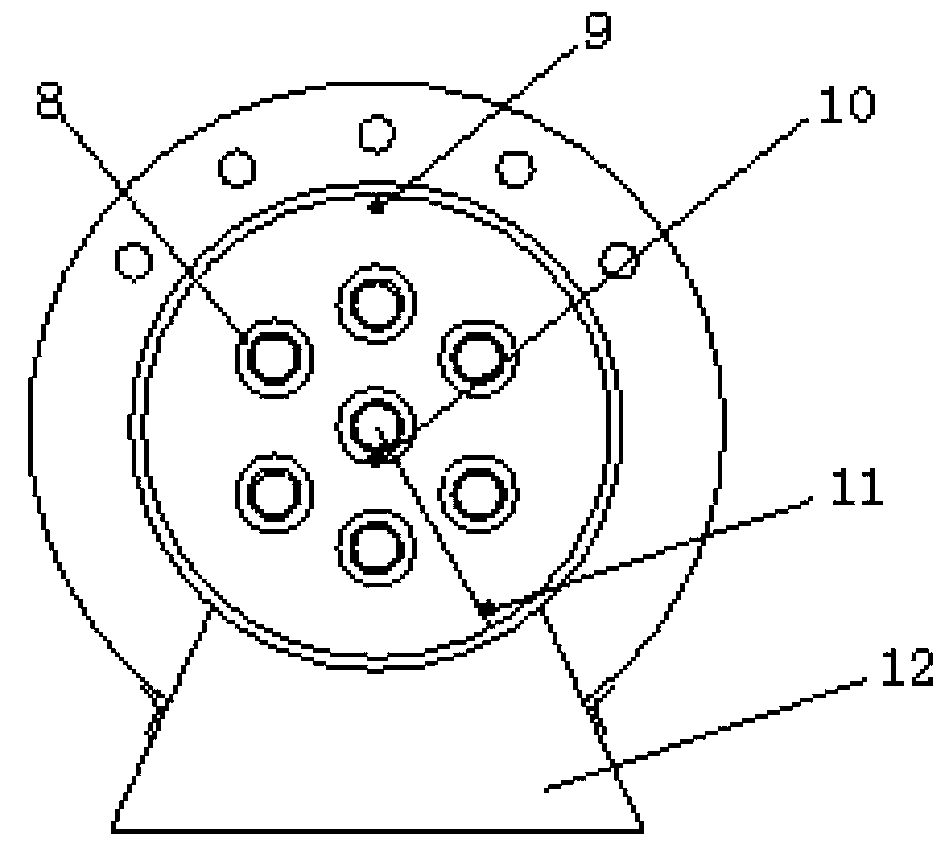

Vacuum imidizing furnace and imidizing method of polyamide acid fiber

A technology of vacuum imidization furnace and evacuated tube, applied in the field of polymers, can solve the problems of filament doubling, uneven heat radiation temperature, low fiber performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The polyamic acid fiber to be treated is imidized using the vacuum imidization furnace provided by the present invention, the vacuum degree is about 0.4mmHg-0.5mmHg, the thermal imidization temperature is raised from 20°C to 350°C, and the temperature is raised The speed is 25°C / min.

Embodiment 2

[0083] The polyamic acid fiber to be treated is imidized using the vacuum imide furnace provided by the present invention, the vacuum degree is about 0.4mmHg-0.5mmHg, the thermal imidization temperature rises from 20°C to 530°C, and the heating rate 30°C / min.

[0084] The results show that the breaking strength of the polyimide fiber obtained in this example is 1.81GPa, the modulus is 18.95GPa, and the breaking elongation is 9.32%.

Embodiment 3

[0086] The polyamic acid fiber to be treated is imidized using the vacuum imidization furnace provided by the present invention. The speed is 15°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com