Heat-pump-assisted wine-brewing distillation automatic-control system with electric-heating wine steamer

An automatic control system and auxiliary technology, applied in the preparation of alcoholic beverages, etc., can solve problems such as energy waste and environmental pollution, and achieve the effect of reducing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] The invention makes full use of the energy-saving and pollution-free advantages of the high-temperature heat pump hot water unit, heats the hot water to about 70°C to 95°C, and then uses the electric heating device to reheat the high-temperature hot water from the heat pump to directly produce the wine retort distillation plant Steam is required. Both the heat pump water heater unit and the electric heating device for the wine retort are directly applied to electricity, so the system does not discharge pollutants. The heat pump water heater unit is used as the first heating device for cold water, and its energy efficiency ratio is as high as 3-5, and its energy-saving effect is obvious.

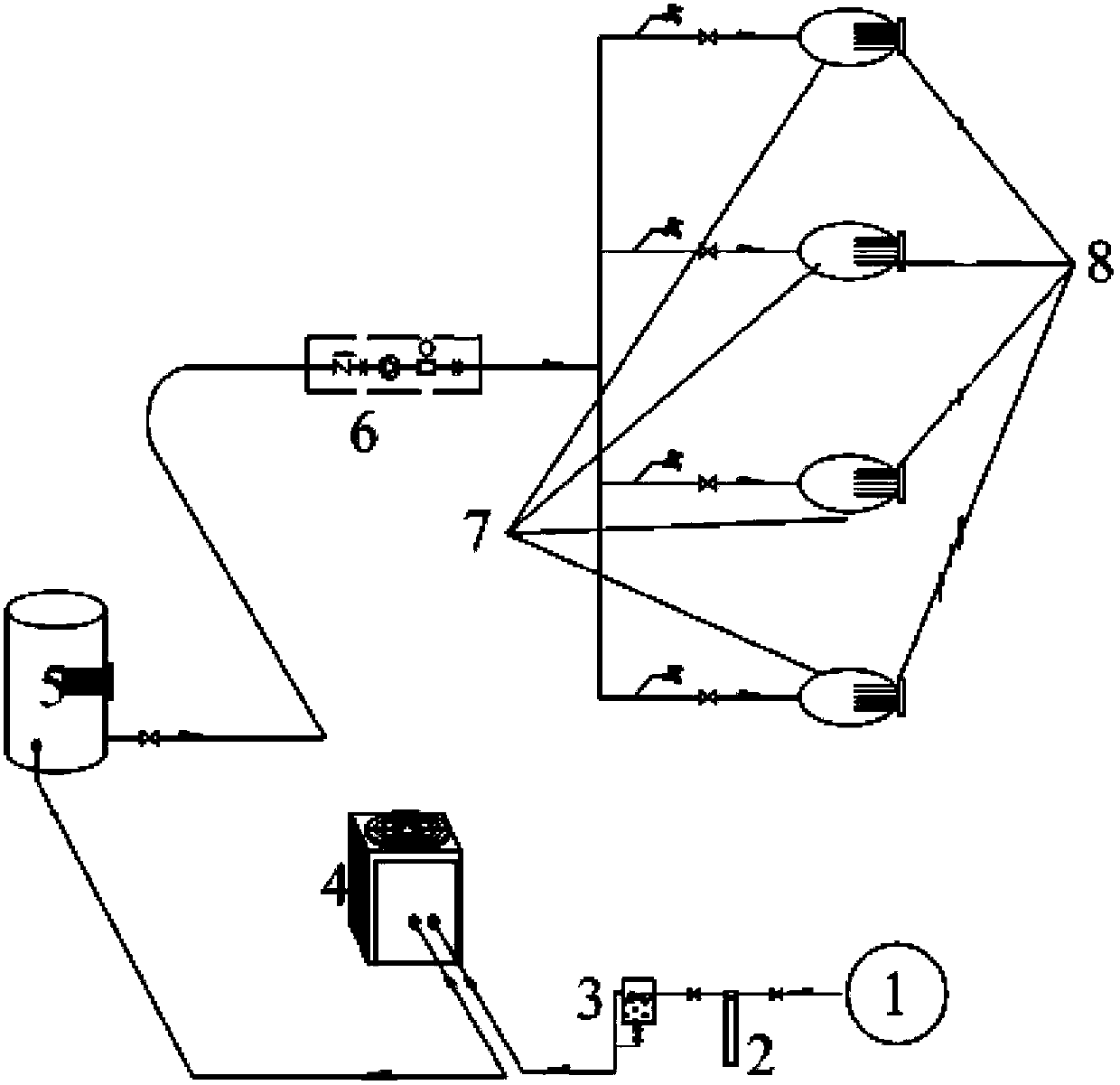

[0021] like figure 1 As shown, the tap water supply pipe 1 enters the water softener 2 through the pipeline, and the water softener 2 removes the hardness component...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap