Determination method of accurate undeformed cutting thickness for complex path with runout

A technology of cutting thickness and complex path, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

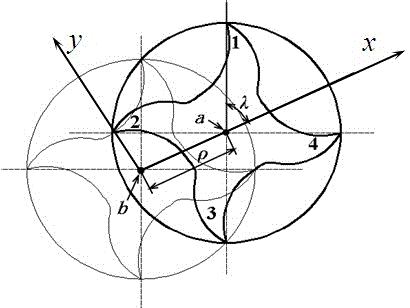

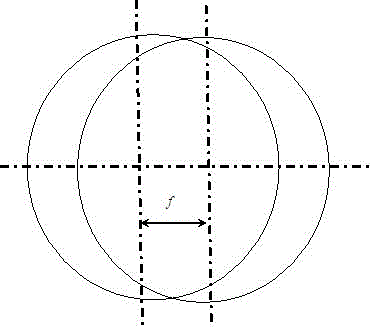

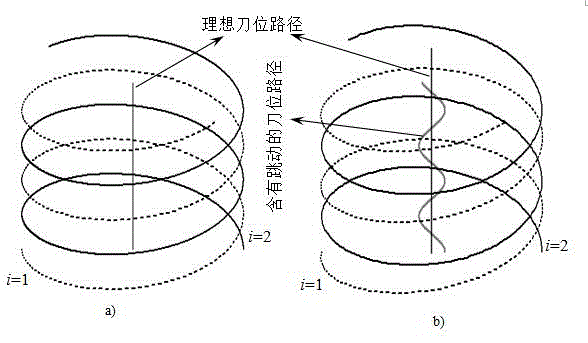

[0055] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. In CNC machining, it is often necessary to optimize the feed rate, customize the machining parameters, etc. The necessary condition for all of this is to accurately predict the milling force during the machining process. The key to predicting the milling force is: the determination of the cutting force coefficient and the undeformed cutting thickness. Accurate calculation and cutting edge participation in cutting judgment. As an important parameter for accurate calculation of cutting force, the solution accuracy of undeformed cutting thickness directly determines the prediction accuracy of cutting force. In order to improve the prediction accuracy, the present invention proposes a method for determining the accurate undeformed cutting thickness of complex path with jump. Include the following steps:

[0056] Ⅰ. Measure the tool runout ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com