A concave-convex die-cutting molding die

A technology of forming molds and concave-convex molds, applied in decorative arts, metal processing, embossed decorative parts, etc., can solve problems such as affecting product die-cutting quality, increasing product rejection rate, and increasing production costs, and achieves improved graphics and texts. The effect of reducing height drop and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

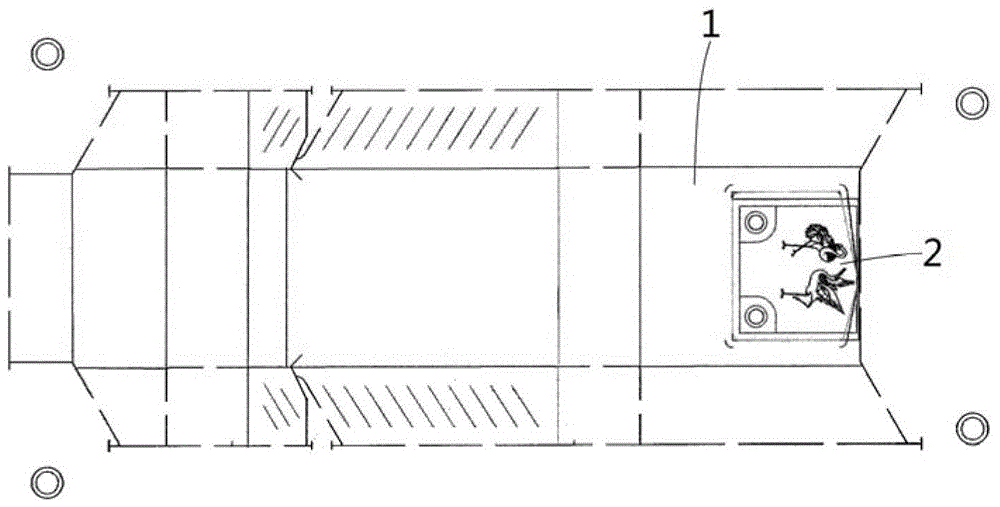

[0013] Such as figure 1 As shown, the concave-convex die-cutting one-time molding mold proposed by the present invention includes a base plate 1 and a convex plate 2, and the base plate 1 has a mounting groove, and the convex plate 2 is arranged on the base plate 1 through the mounting groove, and the bottom of the convex plate 2 is located in the mounting groove. , the top of which protrudes from the installation groove, and the engraving pattern of the convex formwork 2 is located on the top;

[0014] There is adhesive glue in the installation groove, and the bottom of the convex formwork 2 is fixed in the installation groove through the adhesive glue;

[0015] In one embodiment of the present invention, the depth of the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com