Novel multi-purpose drying channel of silk-screen machine

A screen machine, multi-purpose technology, applied in the general parts of printing machinery, printing machines, printing and other directions, can solve the problems of no sterilization and disinfection process and moisture on the inner surface of the cigarette case paper, so as to improve the economic benefits of enterprises. , The effect of ensuring air permeability and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

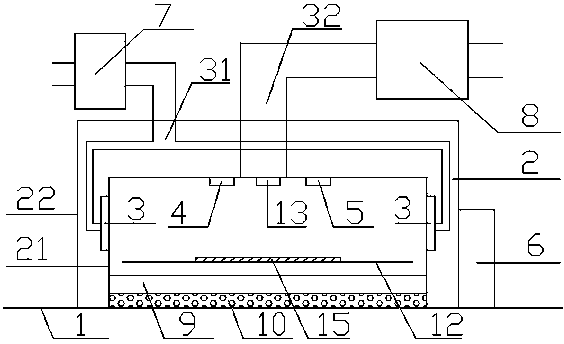

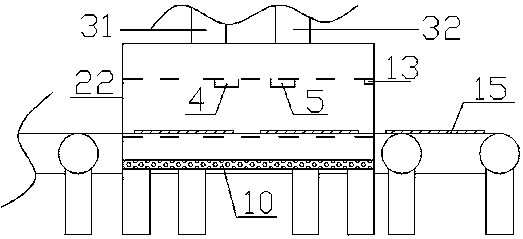

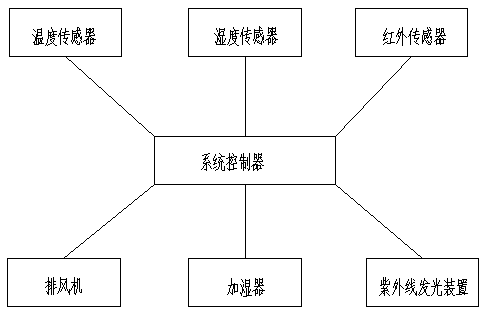

[0025] Example 1: Combining figure 1 and figure 2 It can be seen that the present invention includes a convex drying channel 2 arranged on the workbench 1. The front and rear of the drying channel 2 are open and connected, and the inner wall 21 and the outer wall 22 are hollow structures. Moisture exhaust box 3 is provided on both sides, temperature sensor 4 and humidity sensor 5 are provided on the top of the inner side wall 21, and system controller 6 is provided on the side of the drying tunnel 2. The temperature sensor 4 and humidity sensor 5 All are connected to the system controller 6 through signals, and the top of the drying tunnel 2 is provided with a humidifier 7 and an exhaust fan 8, and the humidifier 7 communicates with two moisture exhaust boxes 3 through a three-way pipe 31, and the exhaust fan 8 is communicated with the inner space of the drying tunnel 2 through the exhaust pipe 32, and an ultraviolet light box 9 is arranged below the drying tunnel 2; the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com