Lifting-opening linkage structure for turn-over airliner cabin door

A flip-up door technology, applied to manual mechanisms, wing leaf control mechanisms, aircraft accessories, etc., can solve the problems of large space occupation, high design difficulty, and complicated linkage, and achieve simple mechanisms, saving weight and space, The effect of institutional simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

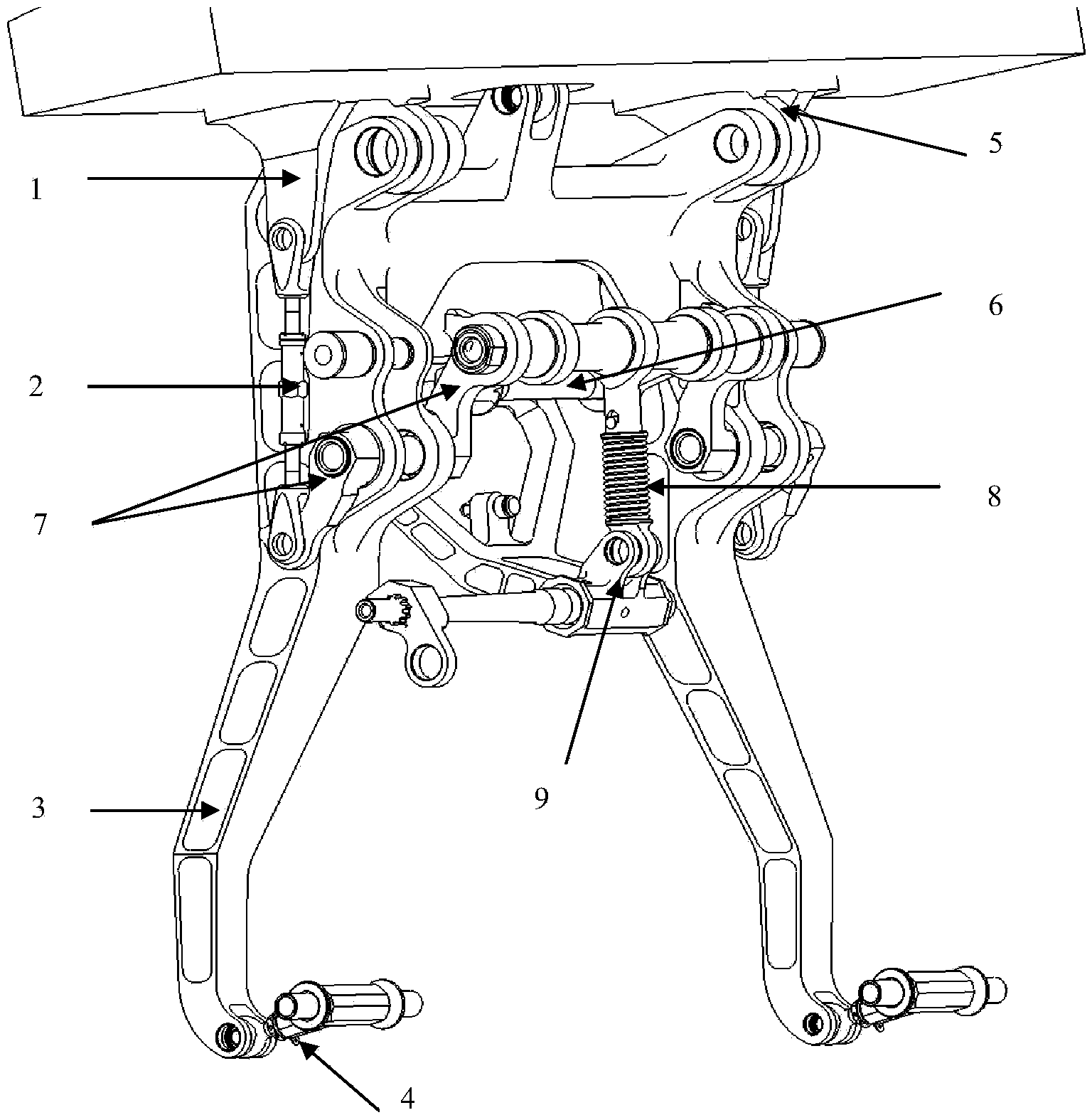

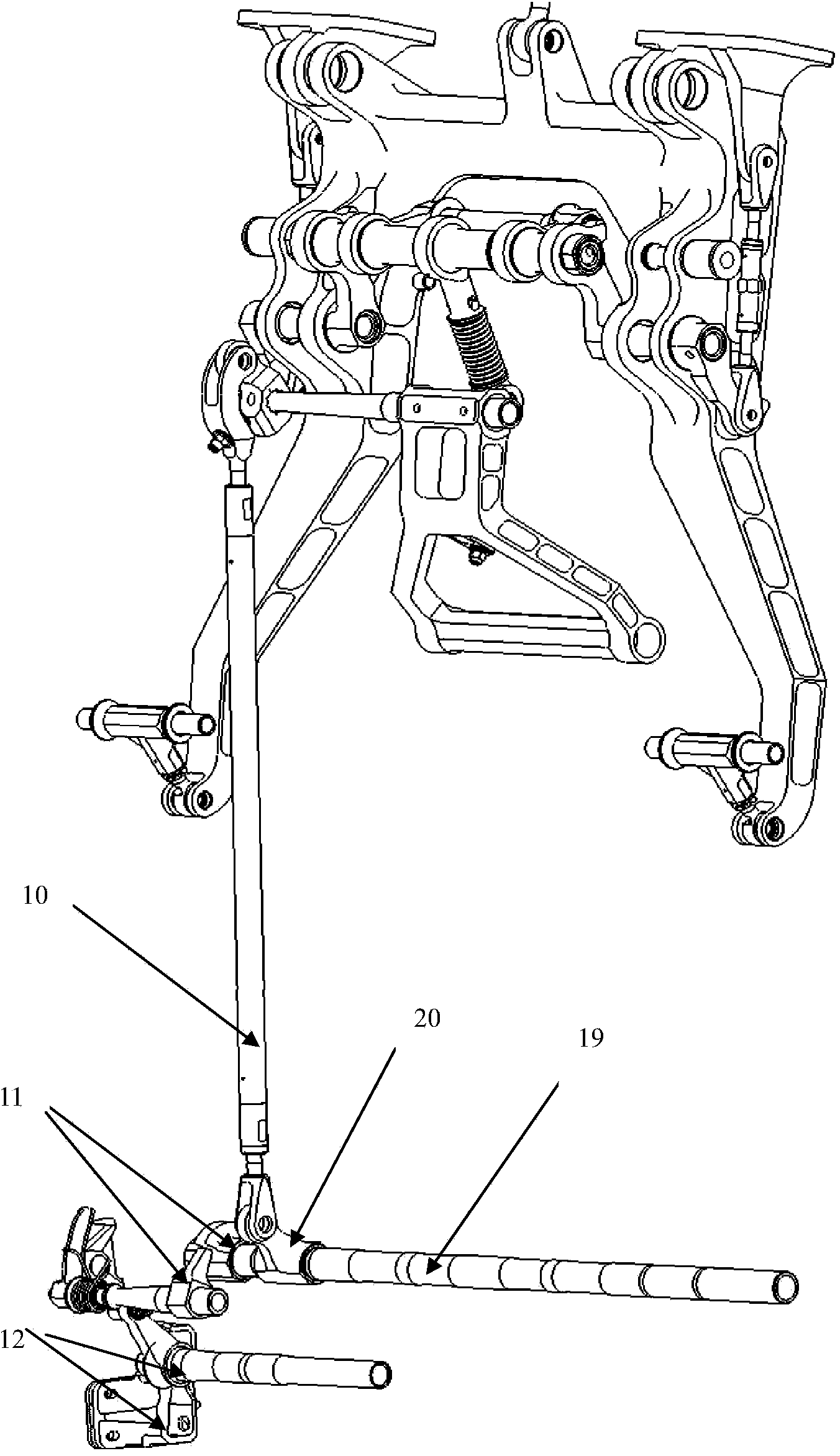

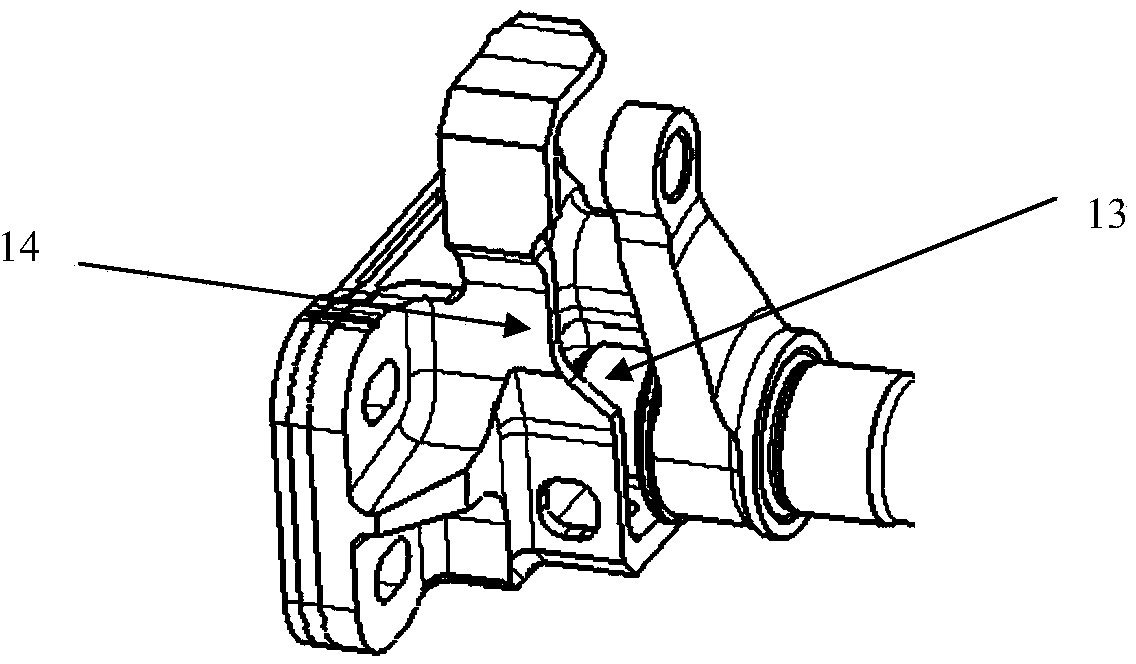

[0023] Below in conjunction with accompanying drawing, structure of the present invention is described in detail:

[0024] Such as figure 1 As shown, the lifting and opening linkage structure of the flip-type airliner cabin door has supports 1 and 5 distributed on both sides of the upper part of the cabin door and fixedly connected with the fuselage structure, a suspension arm 3 with two symmetrical arms, and two symmetrically arranged upper parts. Connecting rod 2, two symmetrically arranged double-arm connecting rods 7, a square connecting rod 6, two symmetrically arranged bottom connecting rods 4, an inner handle 9 hinged with the hatch structure, and connecting connecting rod 6 and inner handle 9 The connecting rod 8; wherein the two ends of the top of the suspension arm 3 are hinged with the support 1 and the support 5 respectively, and one end of the two symmetrical upper connecting rods 2 is respectively hinged with the support 1 and the support 5, and the two arms of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com