Electrical connection structure, terminal structure, and vehicle

A structure and electrical connection technology, which is applied in the direction of conductive connection, motor generator connector, battery/battery traction, etc., to achieve the effect of saving space, improving freedom, and improving vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0065]

[0066] [A-1-1. Overall structure]

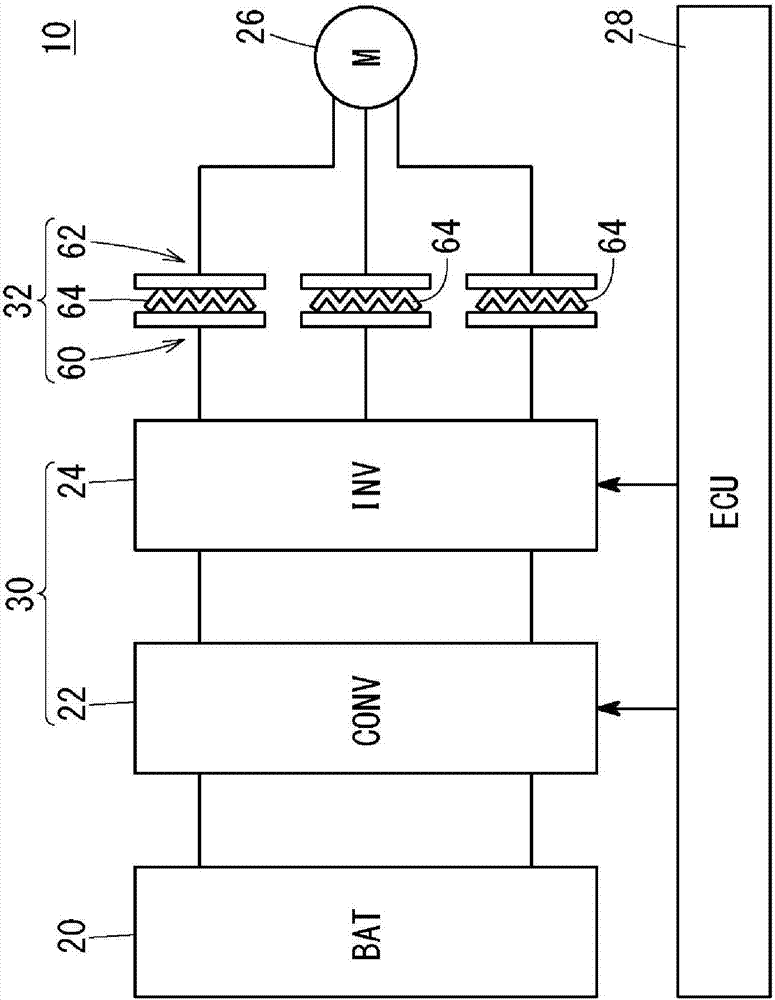

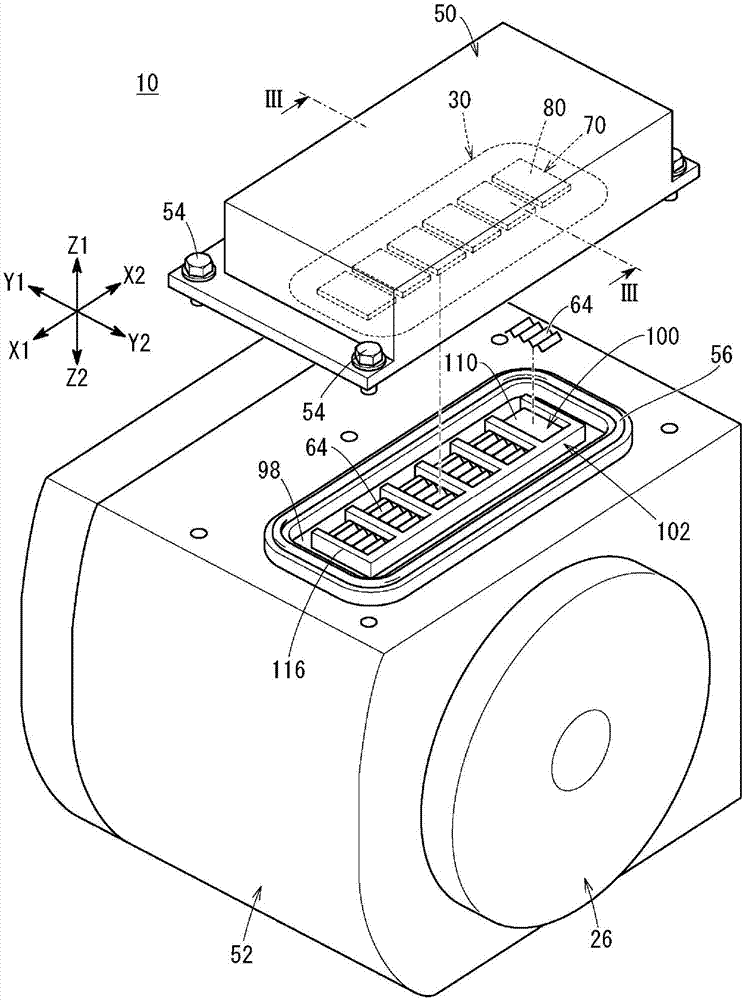

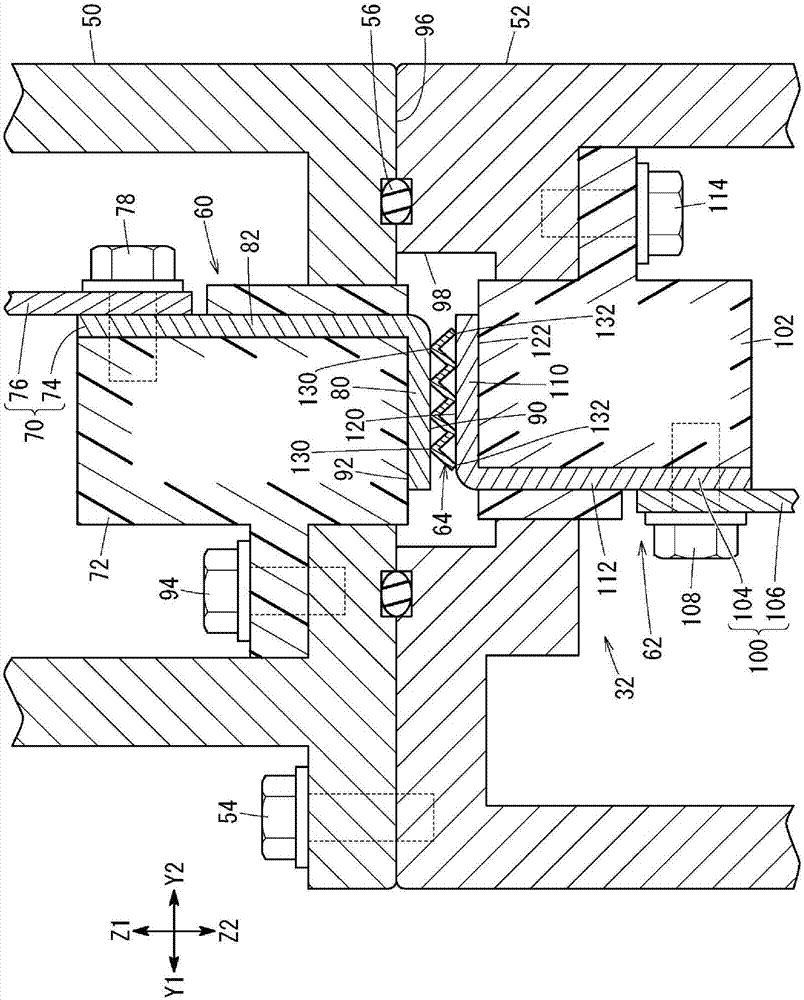

[0067] figure 1 It is a diagram showing a part of electric circuits of the vehicle 10 according to the first embodiment of the present invention. figure 2 It is a perspective view schematically showing a part of the vehicle 10 according to the first embodiment. image 3 is briefly shown figure 2 Sectional view of the III-III line section. figure 2 as well as image 3 Arrows X1 and X2 in the figure represent the front-rear direction of the vehicle 10, arrows Y1 and Y2 represent the width direction of the vehicle 10, and arrows Z1 and Z2 represent the up-down direction of the vehicle 10 (described later). Figure 5 as well as Figure 6 is also the same). The vehicle 10 of the first embodiment is a so-called battery vehicle. Alternatively, vehicle 10 may be an electric vehicle such as a hybrid vehicle.

[0068] Such as figure 1 As shown, the vehicle 10 has a battery 20 , an inverter 22 , an inverter 24 , a travel motor 26...

no. 2 approach

[0126]

[0127] [B-1-1. Overall structure (differences from the first embodiment)]

[0128] Figure 4 It is a diagram showing a part of electric circuits of the vehicle 10A according to the second embodiment of the present invention. Figure 5 It is a perspective view schematically showing a part of the vehicle 10A according to the second embodiment. Figure 6 is briefly shown Figure 5 Sectional view of the section along line VI-VI. The same reference numerals are attached to the same components as those in the first embodiment, and detailed description thereof will be omitted.

[0129] The electrical connection structure 32 of the first embodiment is provided at the portion where the motor 26 and the PCU 30 are connected ( figure 1 ), the first terminal structure 60 is set on the PCU case 50, and the second terminal structure 62 is set on the motor housing 52 ( figure 2 as well as image 3 ). On the other hand, the electrical connection structure 32a of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com