Anti-loose movable pipe connecting device

A technology for anti-loosening and connecting ends, which is applied in the direction of pipes/pipe joints/fittings, sealing surface connection, passing components, etc., which can solve the problems of parts wear, increase of installation work time and cost, and inapplicability, so as to achieve strong applicability and anti-corrosion Loose effect Reliable, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

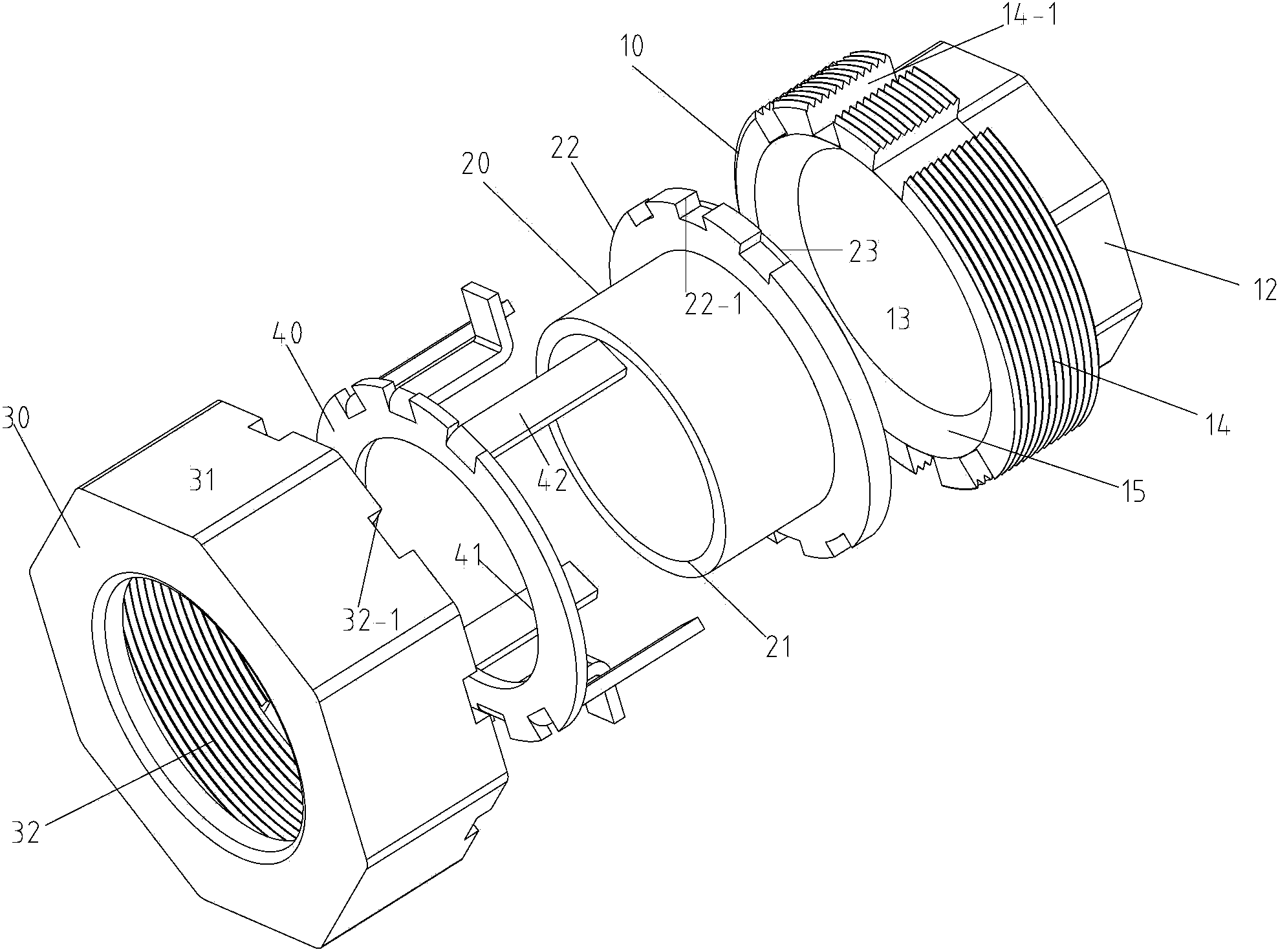

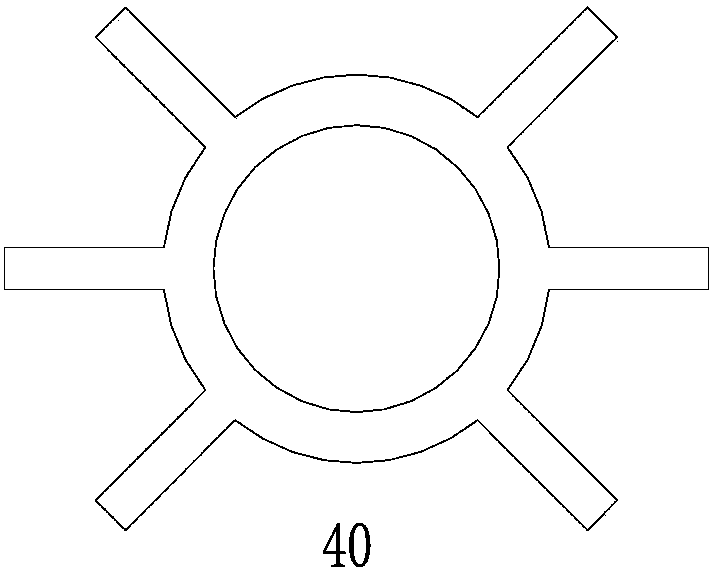

[0019] The anti-loose movable connection device includes bolts 10, fasteners 20, washers 40, and nuts 30. One end of the bolt has an external convex thread 14, and at least one slot 14-1 is opened on the external convex thread along the bolt axial direction. The other end of the fastener is a nozzle 13; one end of the fastener is provided with a flange 22, and at least one slot 22-1 is opened on the flange, and the other end of the fastener 20 is a nozzle 21; the gasket has at least one insertion end 42; said nut has an internal thread 32;

[0020] The fastener 20 is connected with the bolt 10; the washer 40 fits with the fastener 20 through the inner ring 41 and is in close contact with the flange 22 of the fastener, and the insertion end 42 of the washer is inserted into the fastening The slot 22-1 of the piece and the slot 14-1 of the bolt; the nut 30 is screwed into the bolt 10 through the internal thread 32.

[0021] Preferably, the positions and numbers of the slots of ...

Embodiment 2

[0023] Embodiment 2 is a further improvement on Implementation 1.

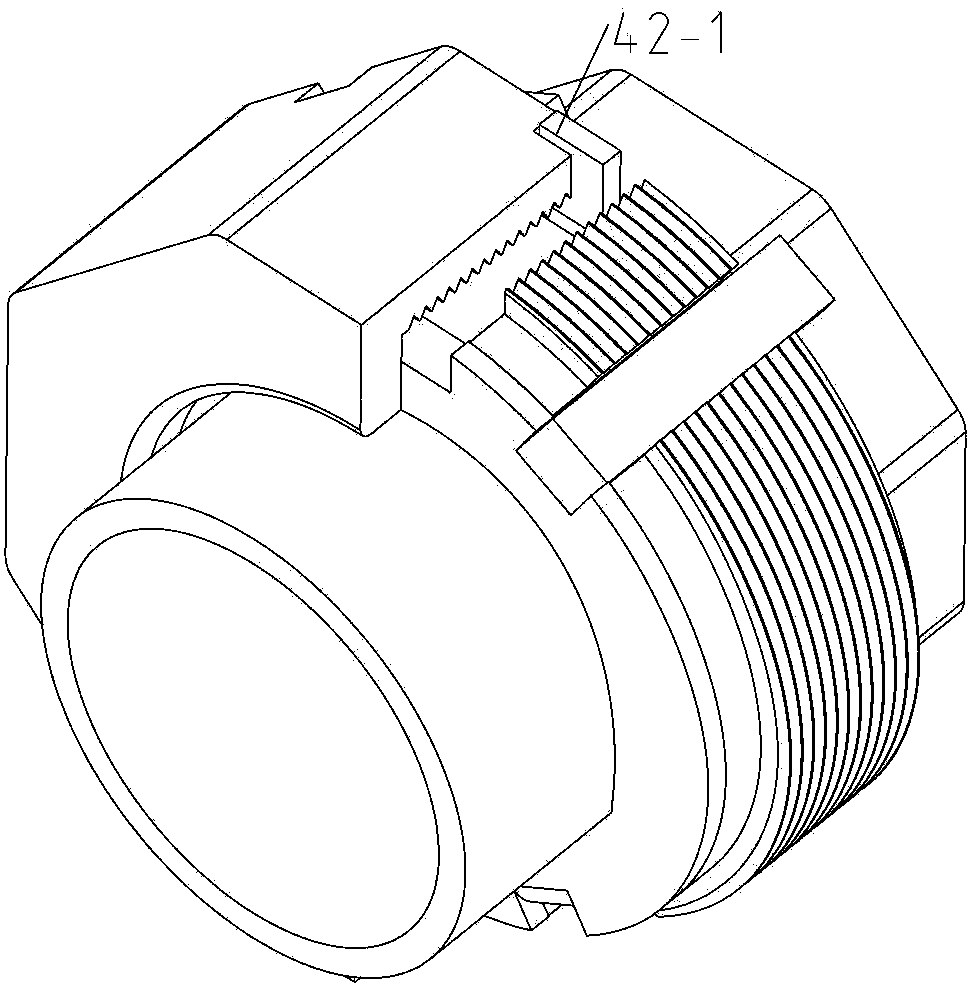

[0024] The anti-loosening movable connection device includes bolts 10, fasteners 20, washers 40, and nuts 30. One end of the bolts has an external convex thread 14, and on the external convex thread 14, there is at least one slot 14-1 along the axial direction of the bolt. The other end of the bolt is a nozzle 13; one end of the fastener 20 is provided with a flange 22, and at least one slot 22-1 is opened on the flange, and the other end of the fastener 20 is a nozzle 21; The washer has at least one insertion end 42; the nut 30 has an internal thread 32, and one end of the nut has at least one groove 32-1 concave to the body;

[0025] The fastener 20 is connected to the bolt 10; the washer 40 is matched with the fastener 20 through the inner ring 41 and is tightly attached to the flange 22 of the fastener, and the insertion end 42 of the washer 40 is inserted into the tight The slot 22-1 of the firmware and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com