Connector with small housing

A technology for connectors and housings, applied in the field of connectors, which can solve the problems of low assembly operability of the connector 301 and easy falling off of the gasket 306, and achieve good assembly operability and prevent parts from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

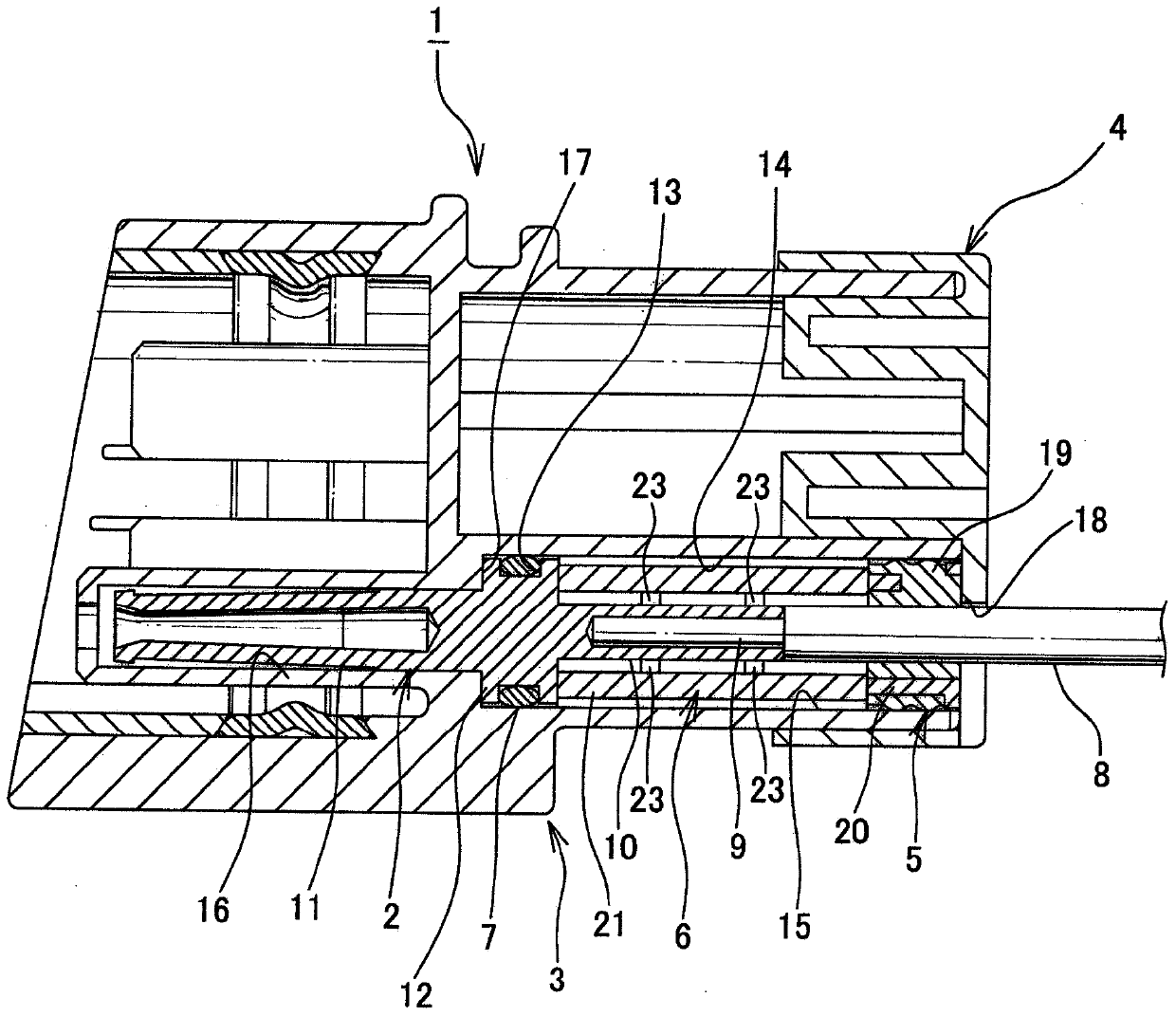

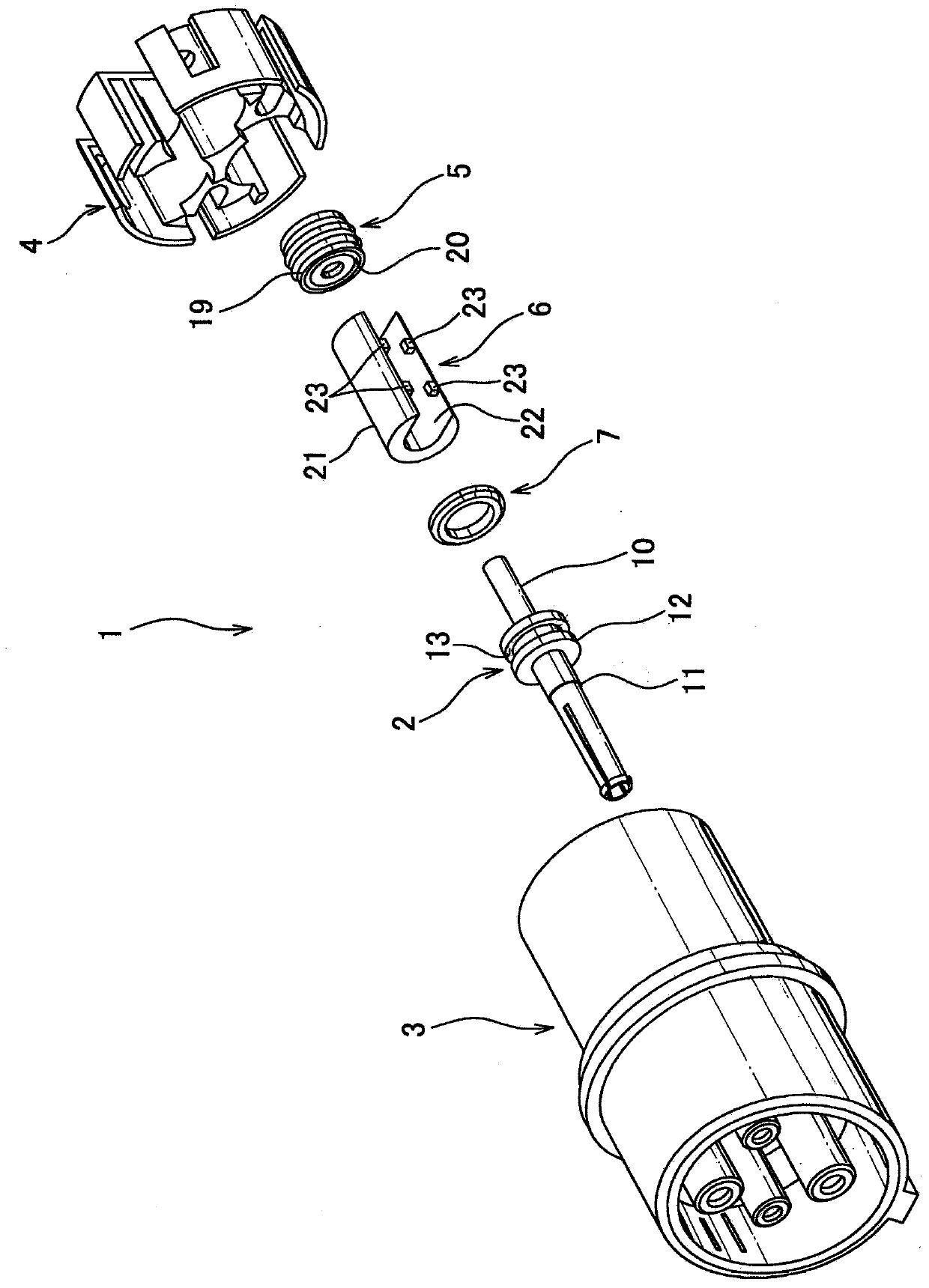

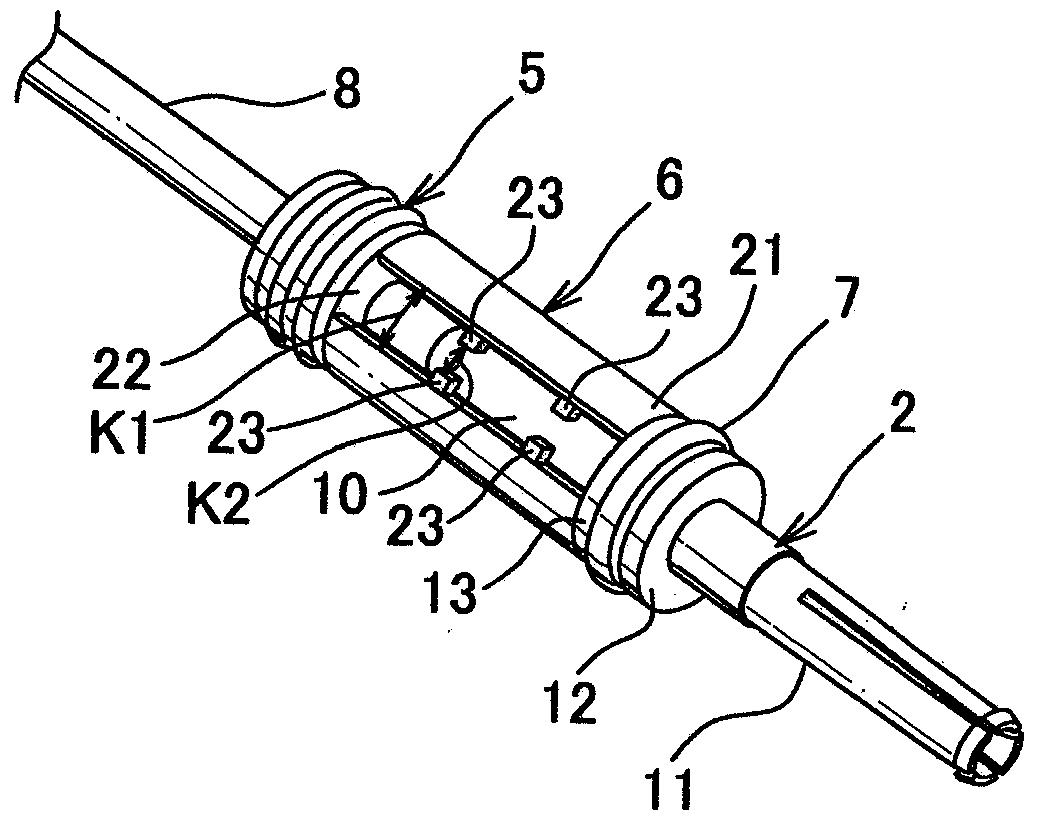

[0050] will refer to Figures 1 to 3 A connector according to one embodiment of the invention is discussed.

[0051] Such as figure 1 , 2 The illustrated connector 1 is provided with: a plurality of terminal fittings 2; a synthetic resin housing 3 provided with a plurality of terminal housings 14 respectively accommodating a plurality of terminal fittings 2; a rear holder 4, the The rear retainer 4 prevents the terminal fittings 2 attached to the end of the housing 3 from falling off from the terminal housing 14; a plurality of rubber packages 5 are press-fitted in each terminal housing 14; A plurality of synthetic resin spacers 6 are housed in the terminal housing 14 , respectively; and a plurality of gaskets 7 are attached to the terminal fittings 2 , respectively. Note that in figure 1 with 2 In , the terminal fittings 2, the rubber packing 5, the gasket 6, and the gasket 7 are shown one by one, while other components are omitted.

[0052] The above-mentioned termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com