Drill bit

A drill bit and drill shank technology, which is used in repairing drills, drilling tool accessories, drilling/drilling equipment, etc., can solve problems such as inconvenience in processing and production, and achieve the effects of simple structure, reasonable design and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

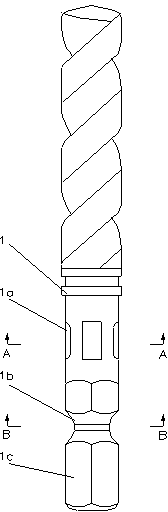

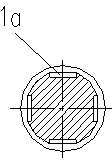

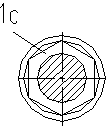

[0010] Such as figure 1 , figure 2 and image 3 As shown, a drill bit of the present invention includes a drill shank 1, and the drill shank 1 includes a section of hexagonal cylinder 1c, see image 3 As shown, the hexagonal cylinder 1c is provided with an annular positioning groove 1b, see figure 2 As shown, the drill shank 1 is also provided with an axial positioning groove 1a. The hexagonal cylindrical drill shank 1 is more suitable for the traditional drill chuck. The hexagonal cylindrical drill shank 1 with a ring-shaped positioning groove 1b is suitable for clamping by a hexagonal converter. , to lock the bit. The drill shank 1 is provided with an axial positioning groove 1a to accommodate different types of converter clamping.

[0011] The above-mentioned examples are only to illustrate the present invention, but not to limit the present invention. The present invention can also be implemented in other ways, which will not be repeated here. Any technical solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com