Embossing device of large-width wallpaper device

A technology of embossing and wallpaper, applied in the direction of mechanical processing/deformation, etc., can solve problems such as uneven distribution of contact pressure, deformation of embossing rollers, and structure that cannot meet the production process requirements of wide-width wallpaper, so as to increase aesthetics, reduce deformation, Three-dimensional effect with obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

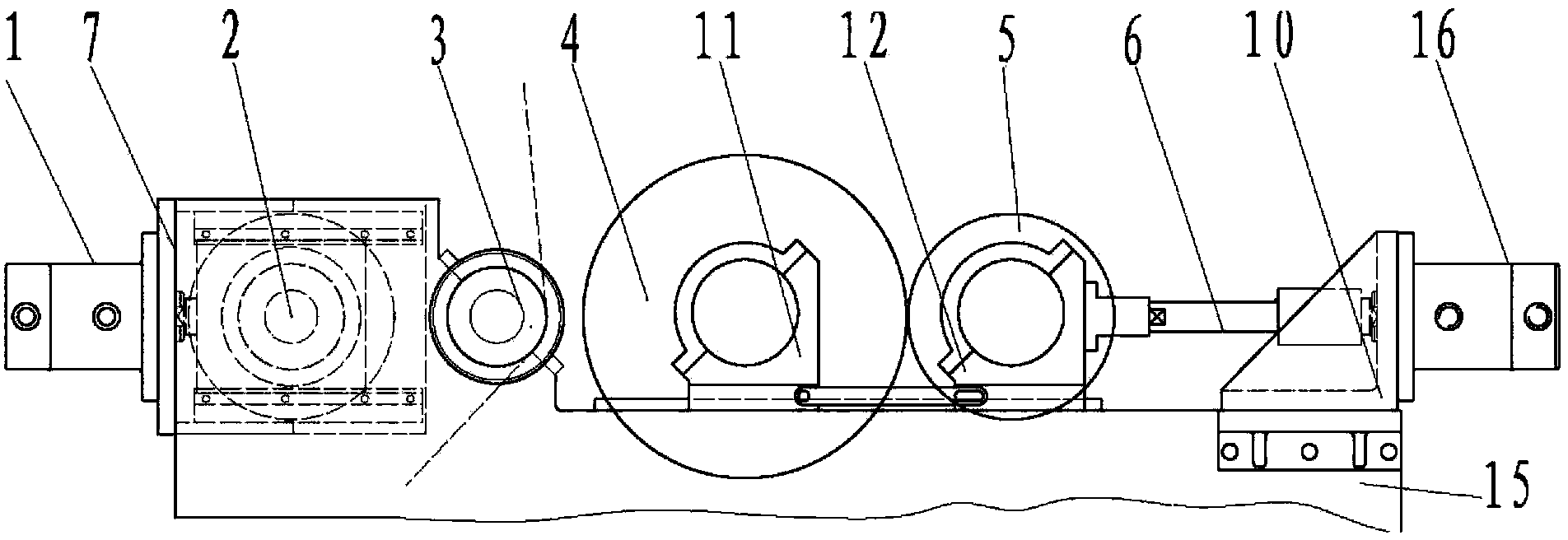

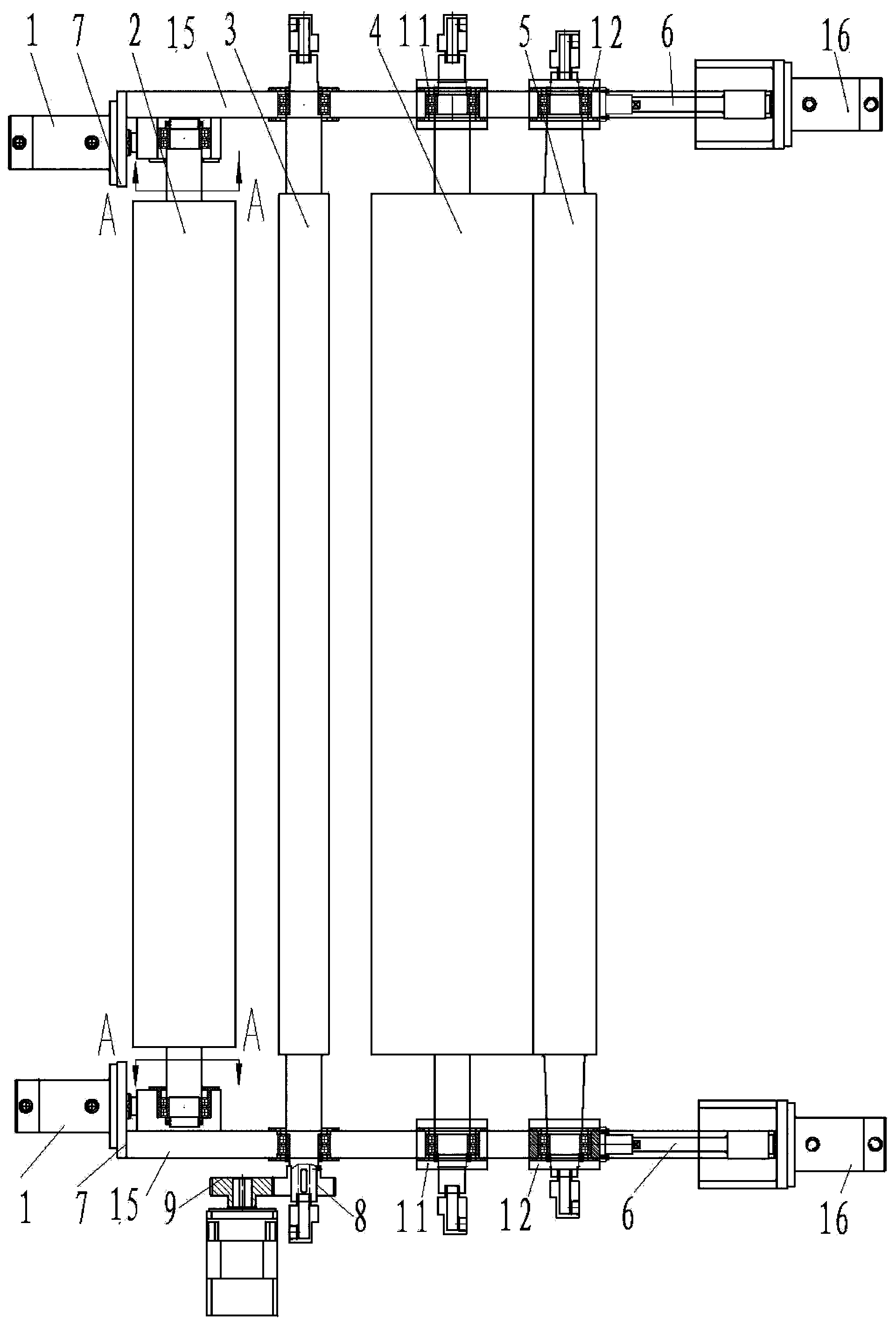

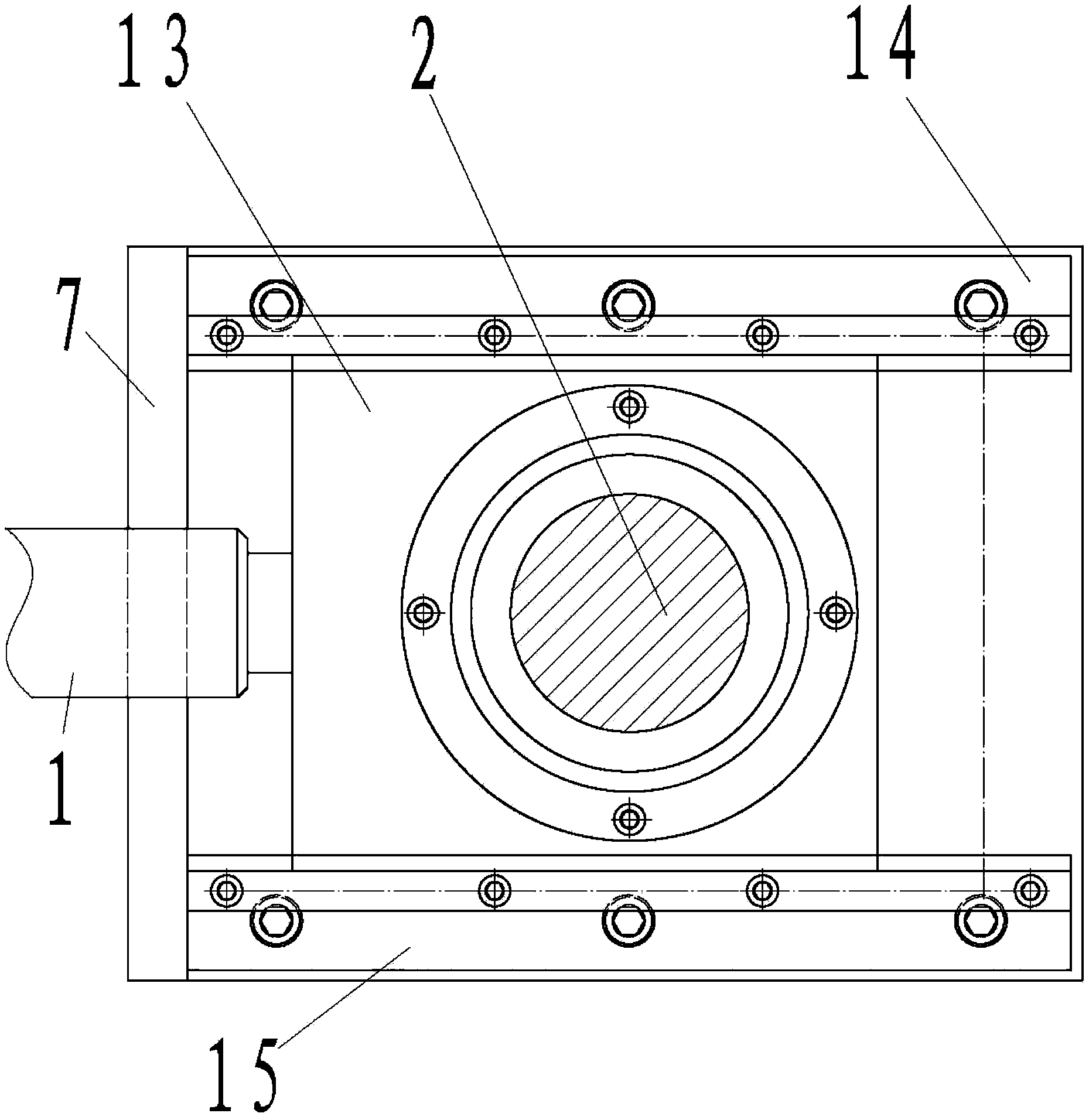

[0019] The embossing unit of the current narrow wallpaper production line, refer to figure 1 The right half of , there are two structures:

[0020] The first is three-roller counter-pressure, that is, through the action of the left embossing cylinder 1, the pressure is transmitted to the connecting rod 6, and the connecting rod 6 is then transmitted to the back pressure steel roller 5, and the back pressure steel roller 5 is transmitted to the embossing rubber roller 4, finally a pressure is formed between the embossing roller 3 and the embossing rubber roller 4, and the pressure generated when the material film passes between the embossing roller 3 and the embossing rubber roller 4 embosses the convex and concave patterns on the material film;

[0021] The other is two rollers against pressure, that is, the pressed steel roller 5 is cancele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com