Patents

Literature

31results about How to "Reduce variant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

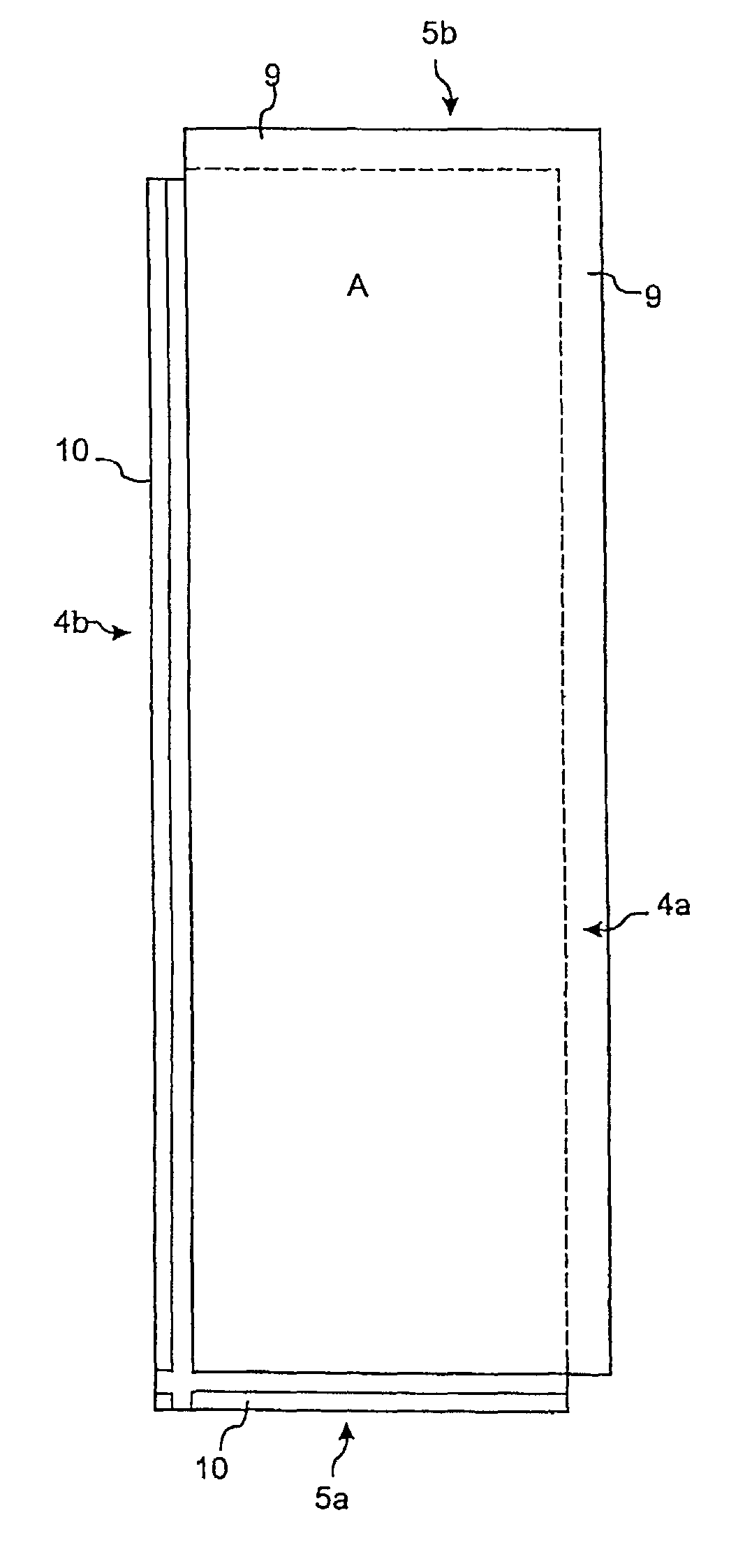

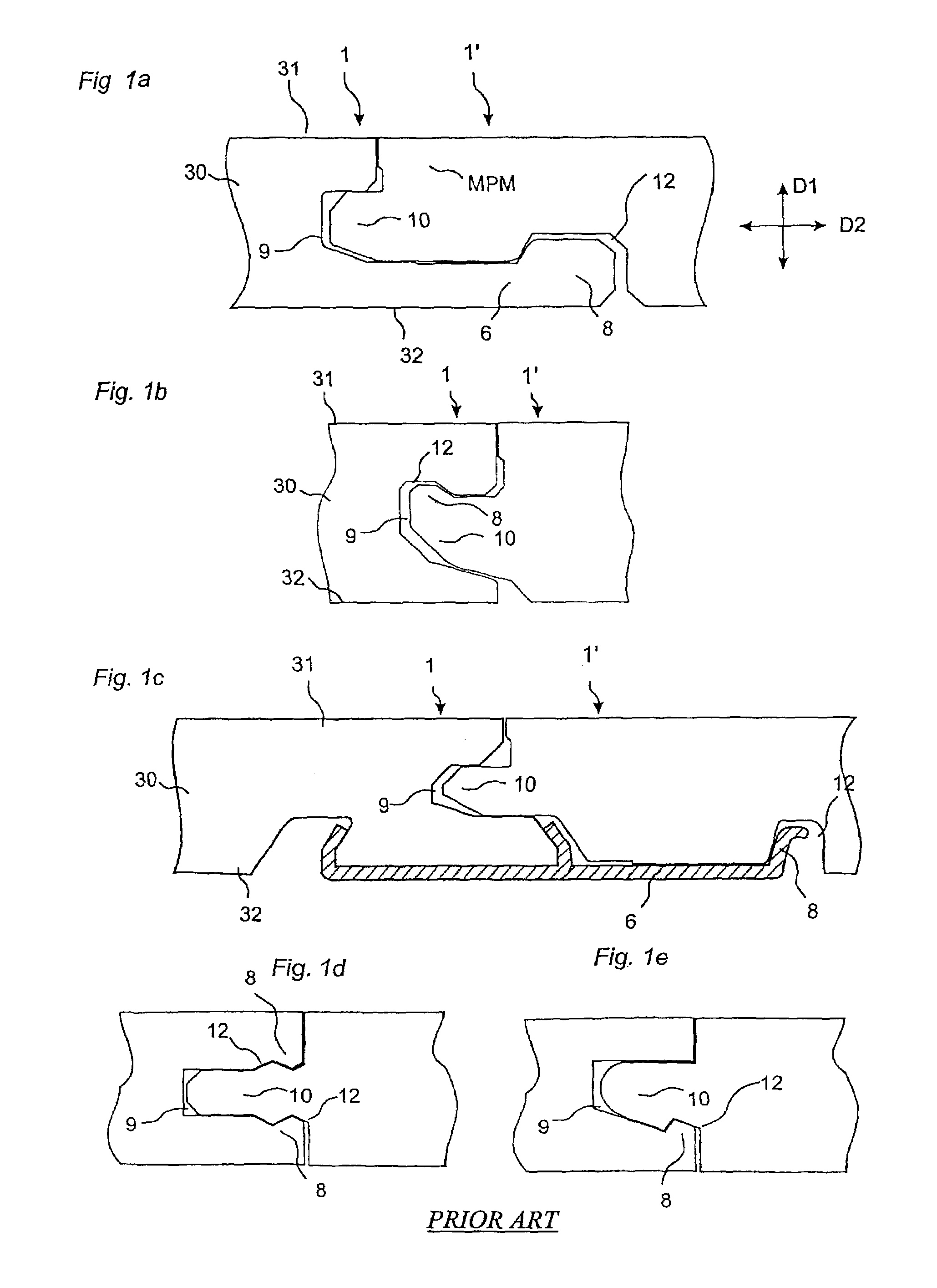

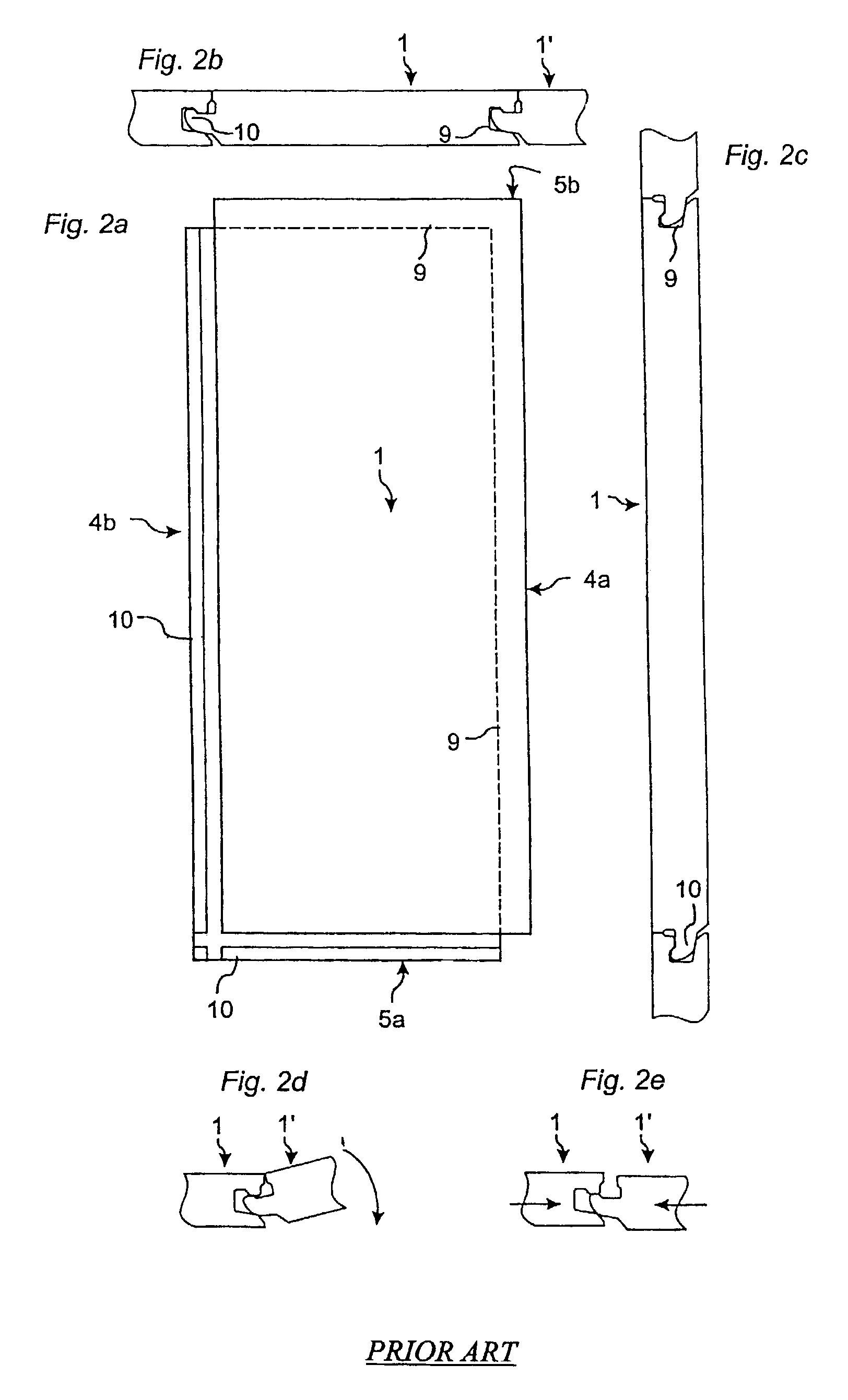

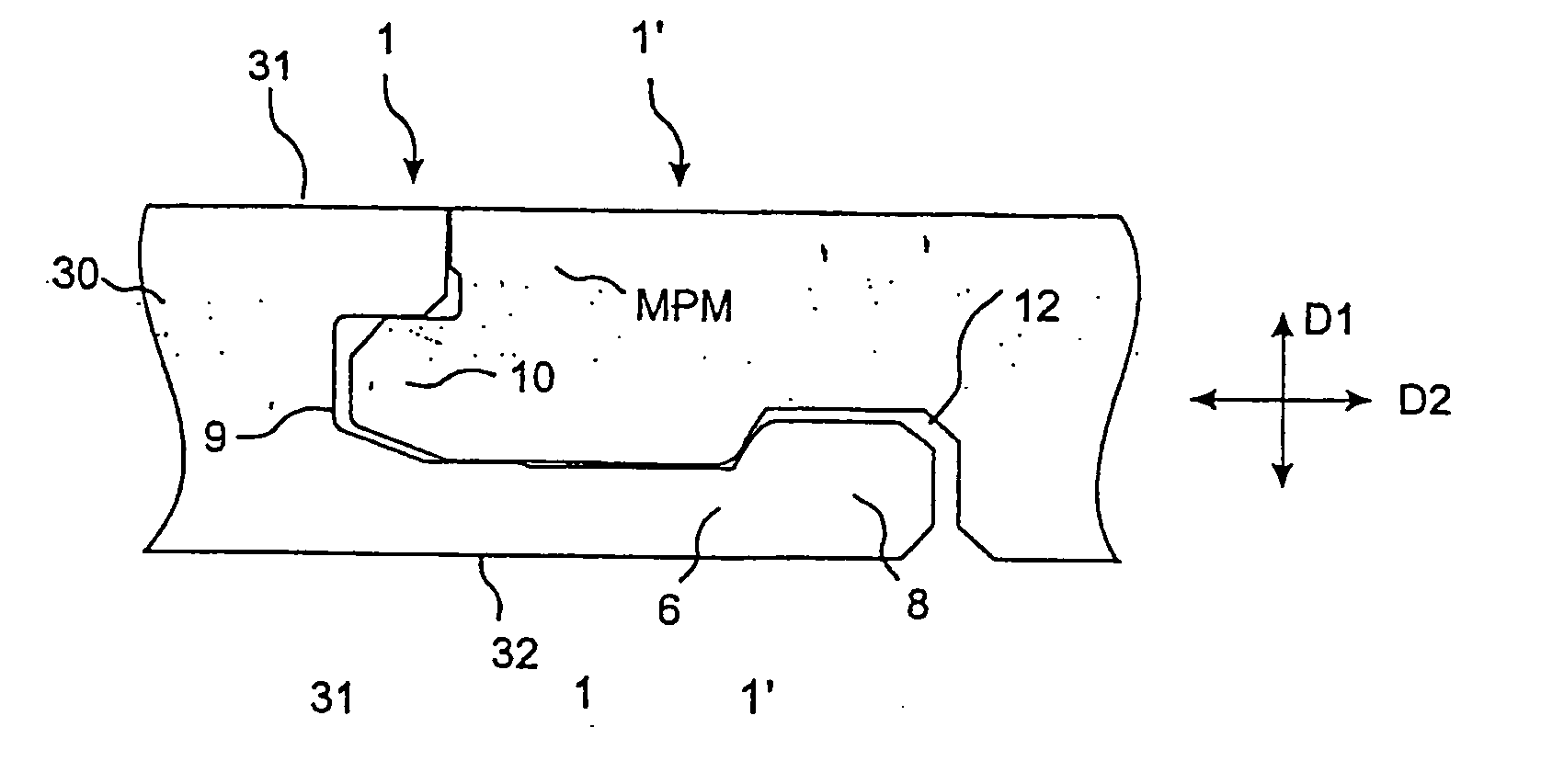

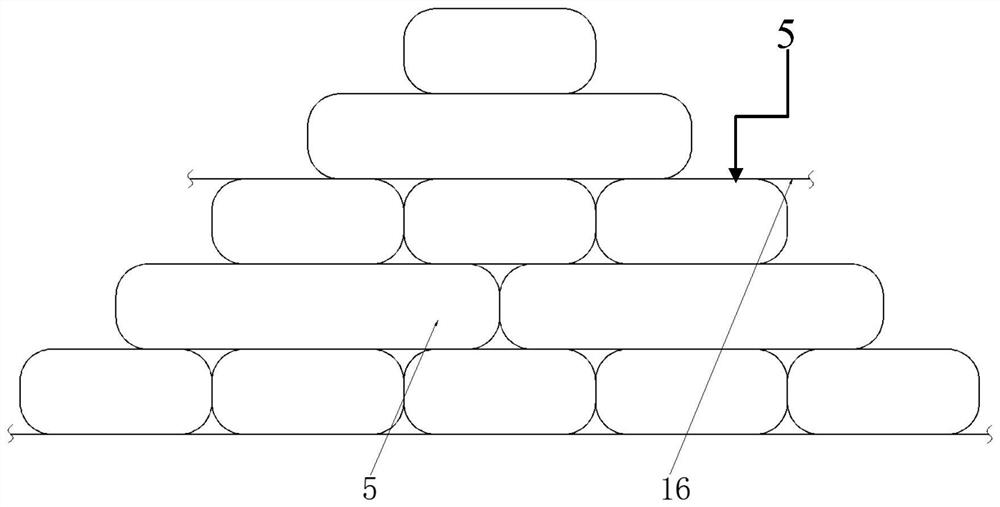

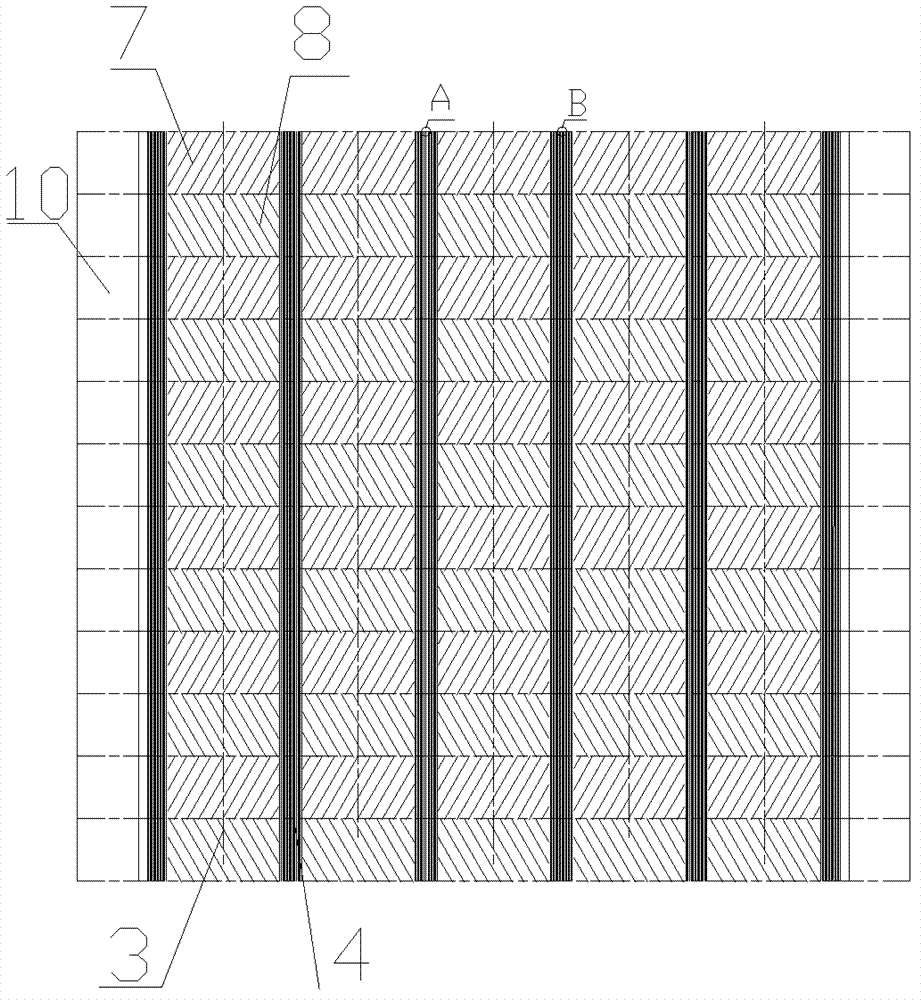

Flooring and method for laying and manufacturing the same

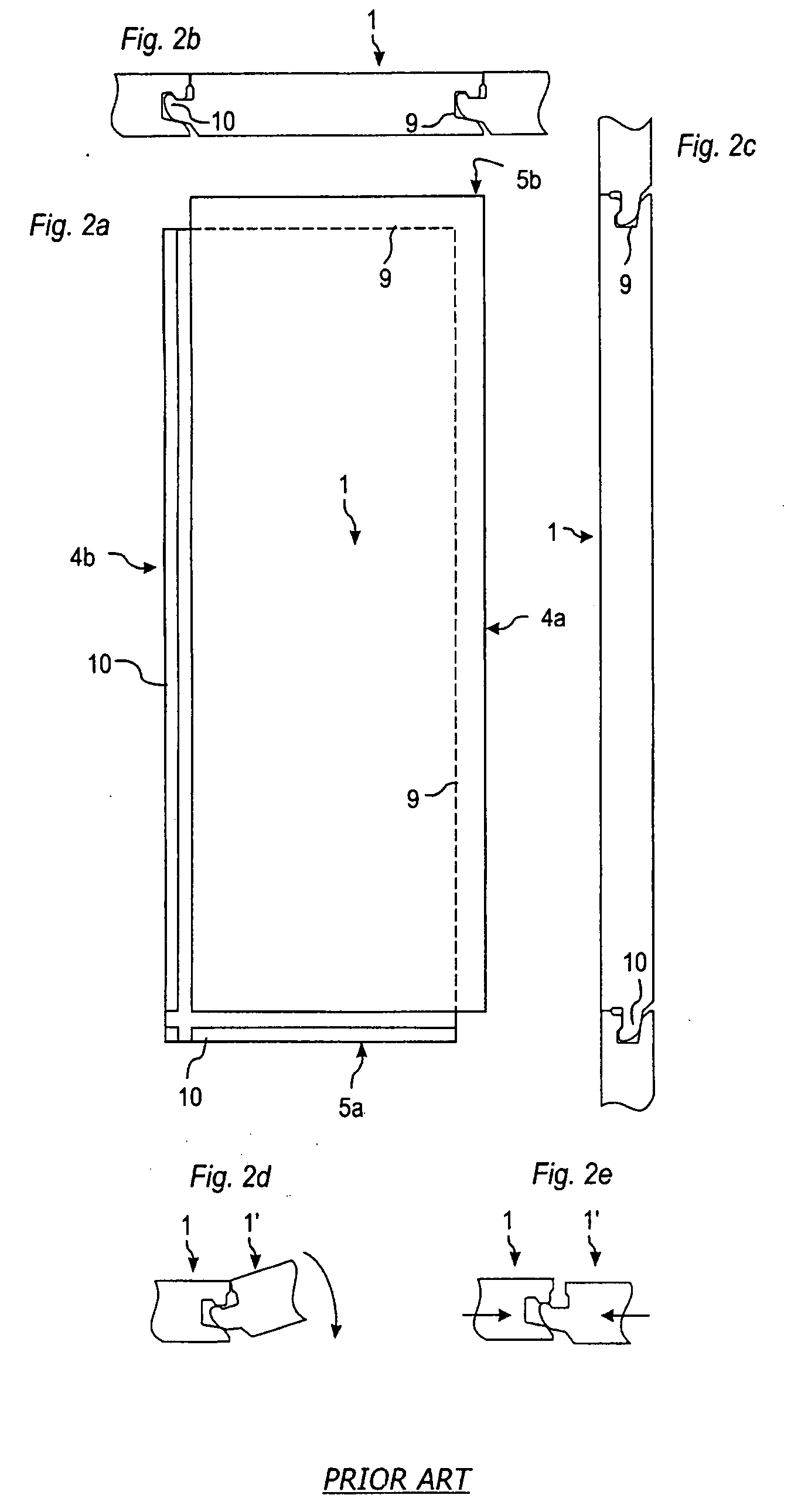

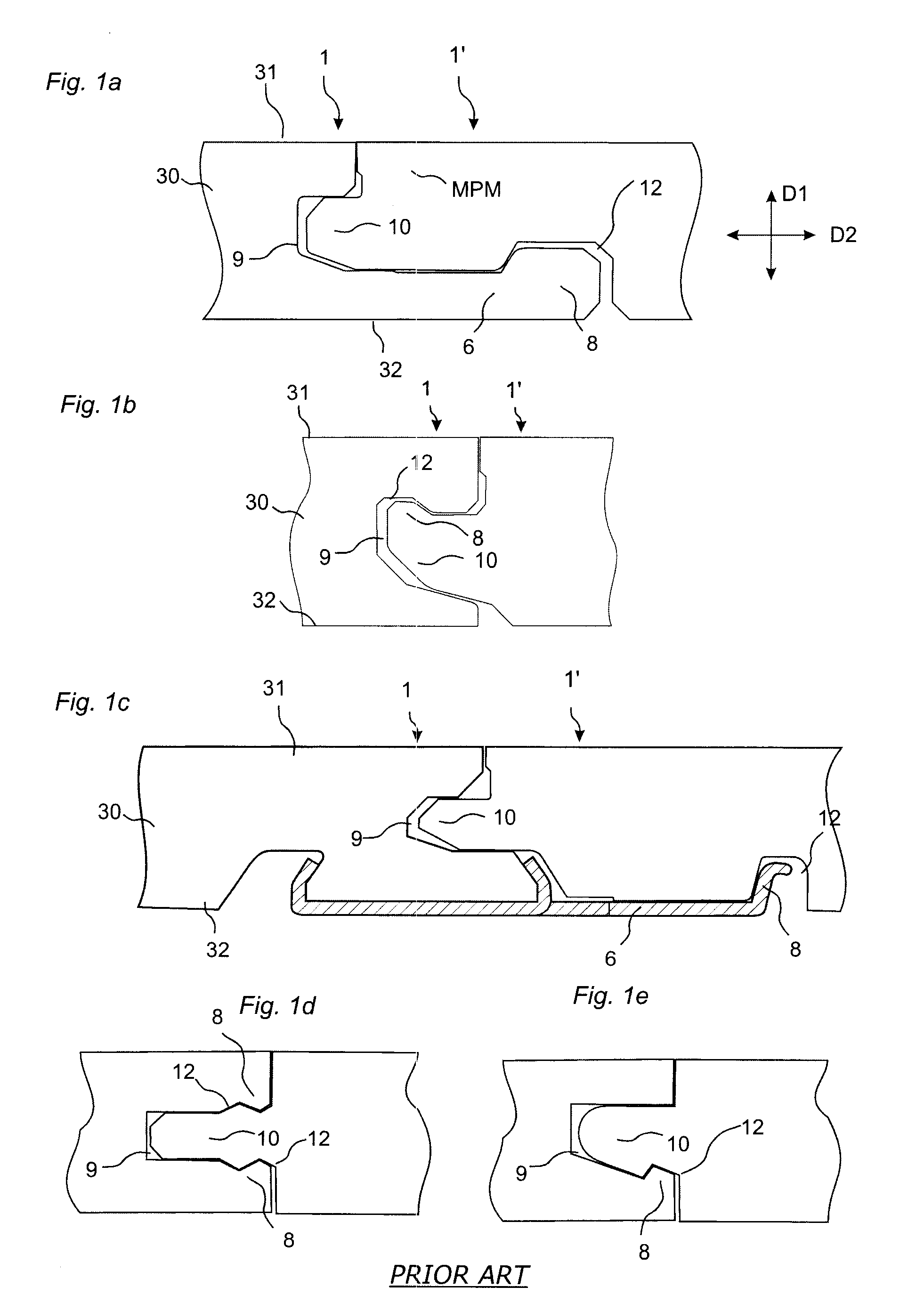

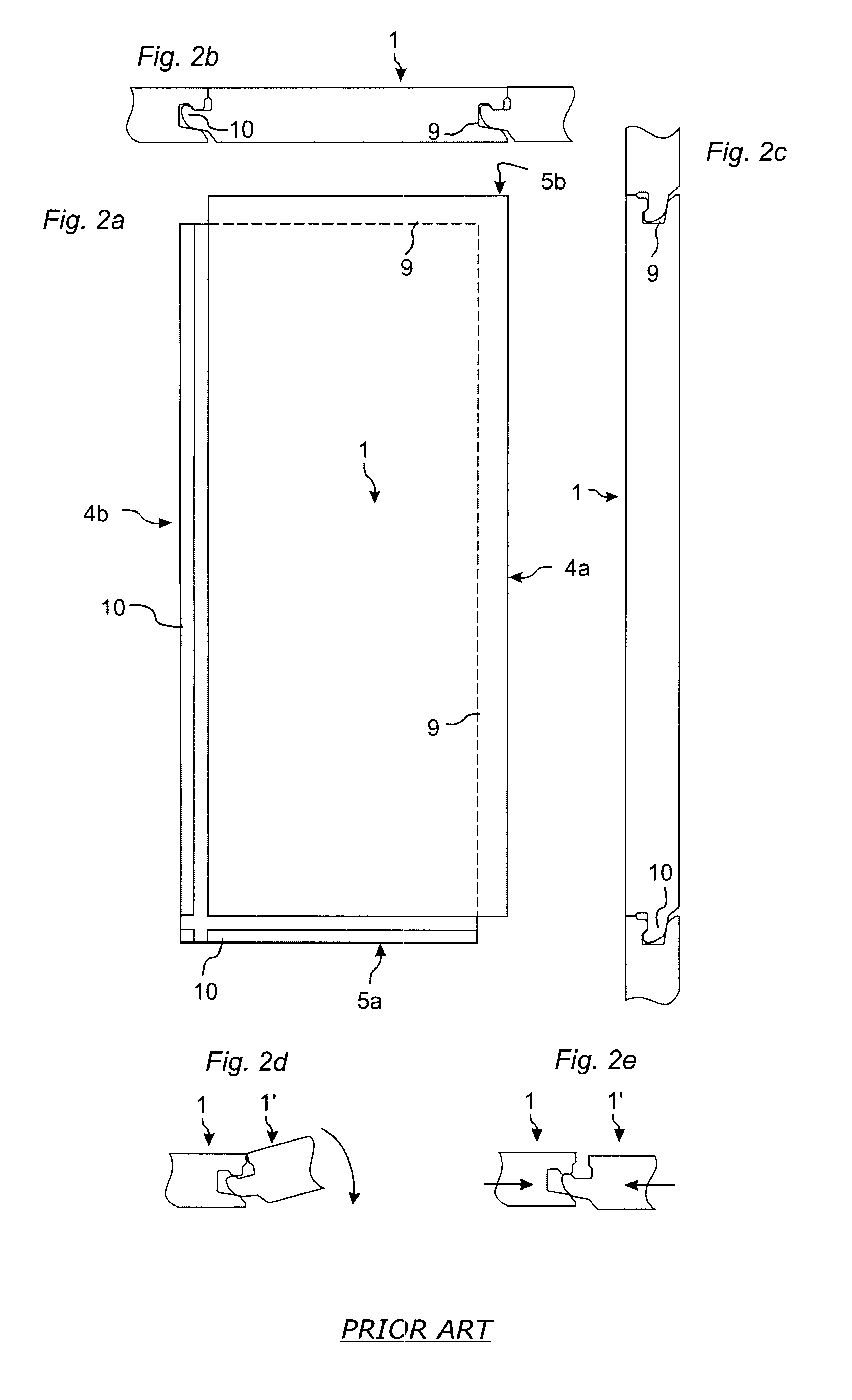

InactiveUS7127860B2The process is simple and fastImprove distributionConstruction materialWallsHerringbone pattern

Owner:VÄLINGE INNOVATION AB

Method Of Making A Floorboard And Method Of Making A Floor With The Floorboard

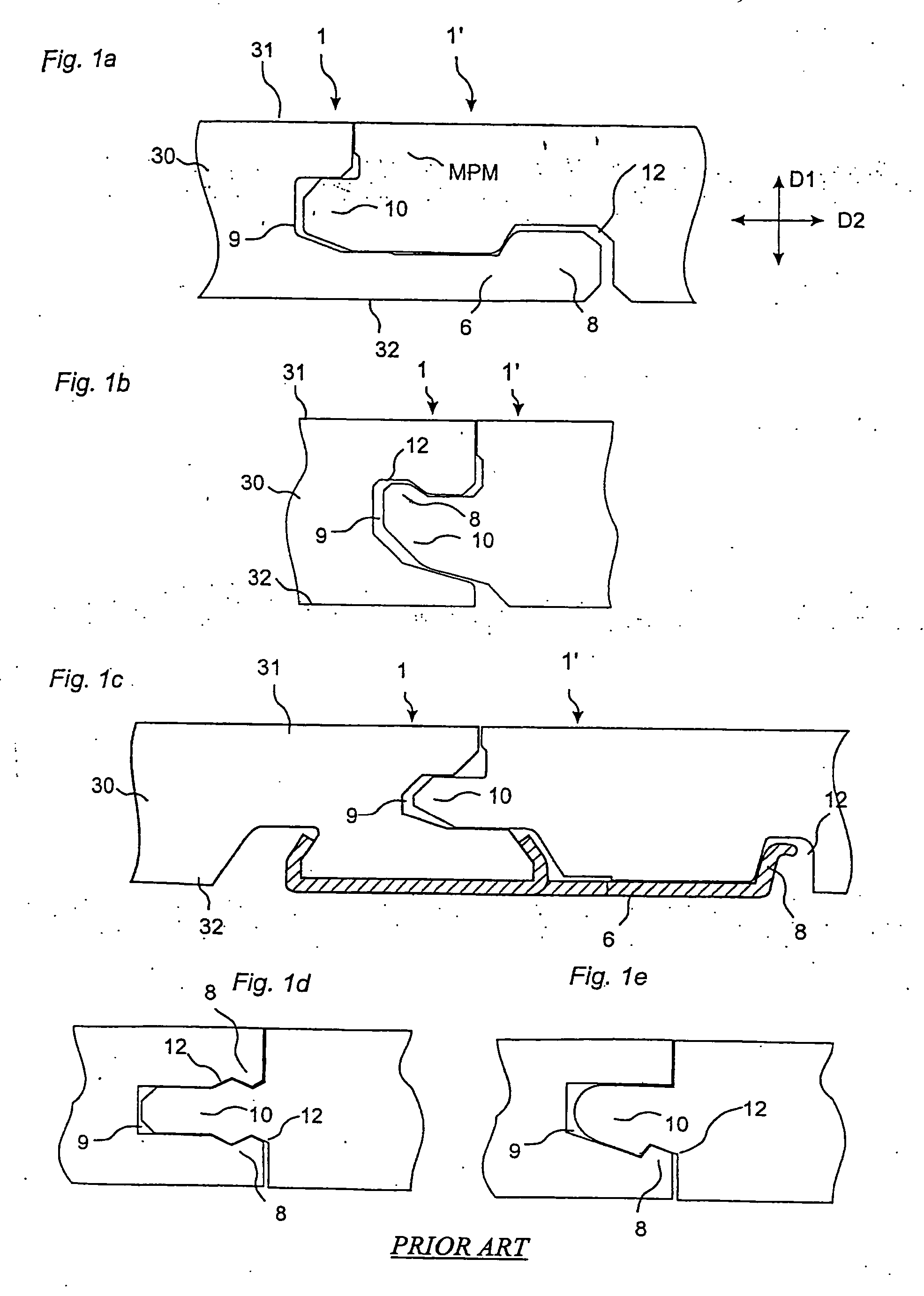

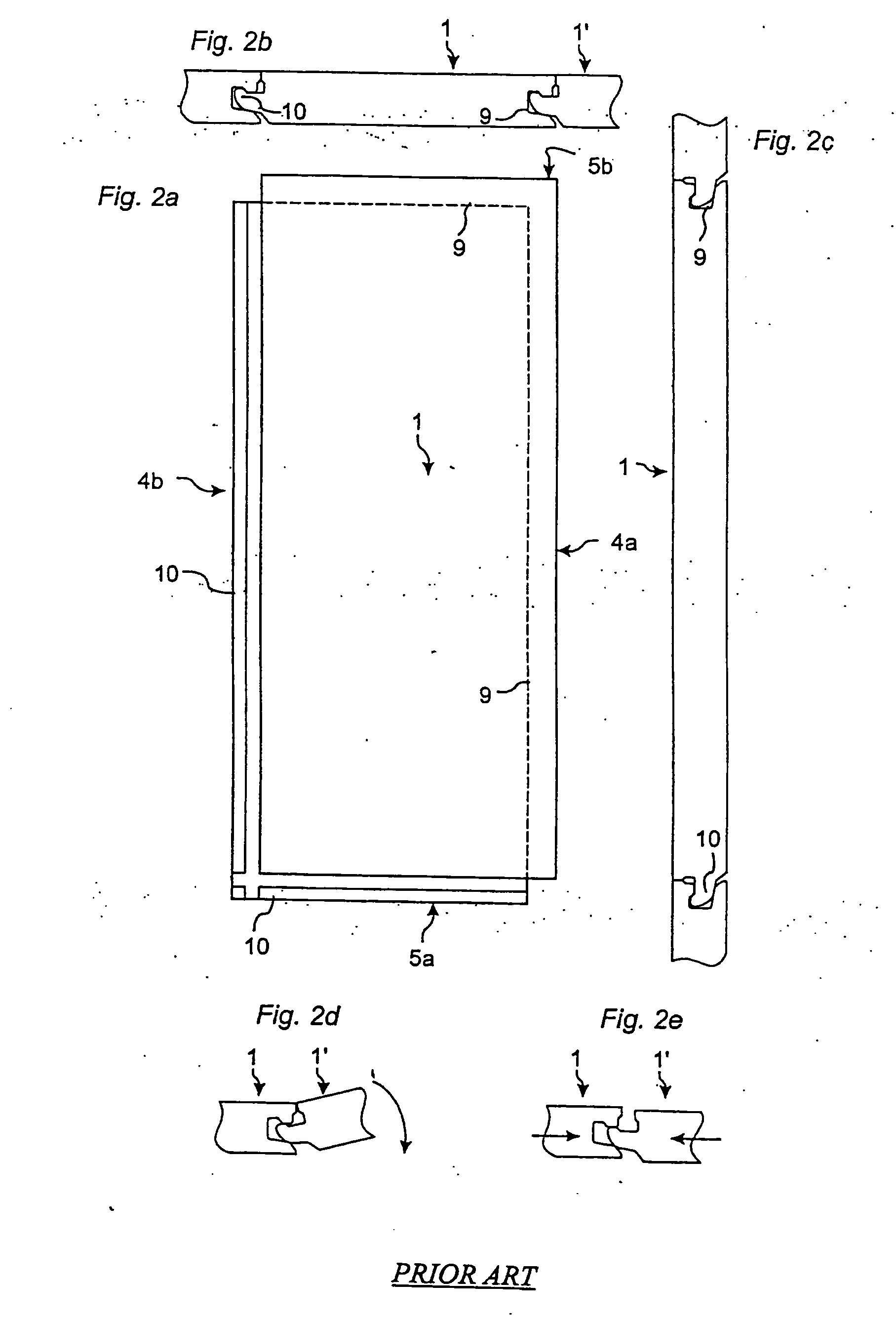

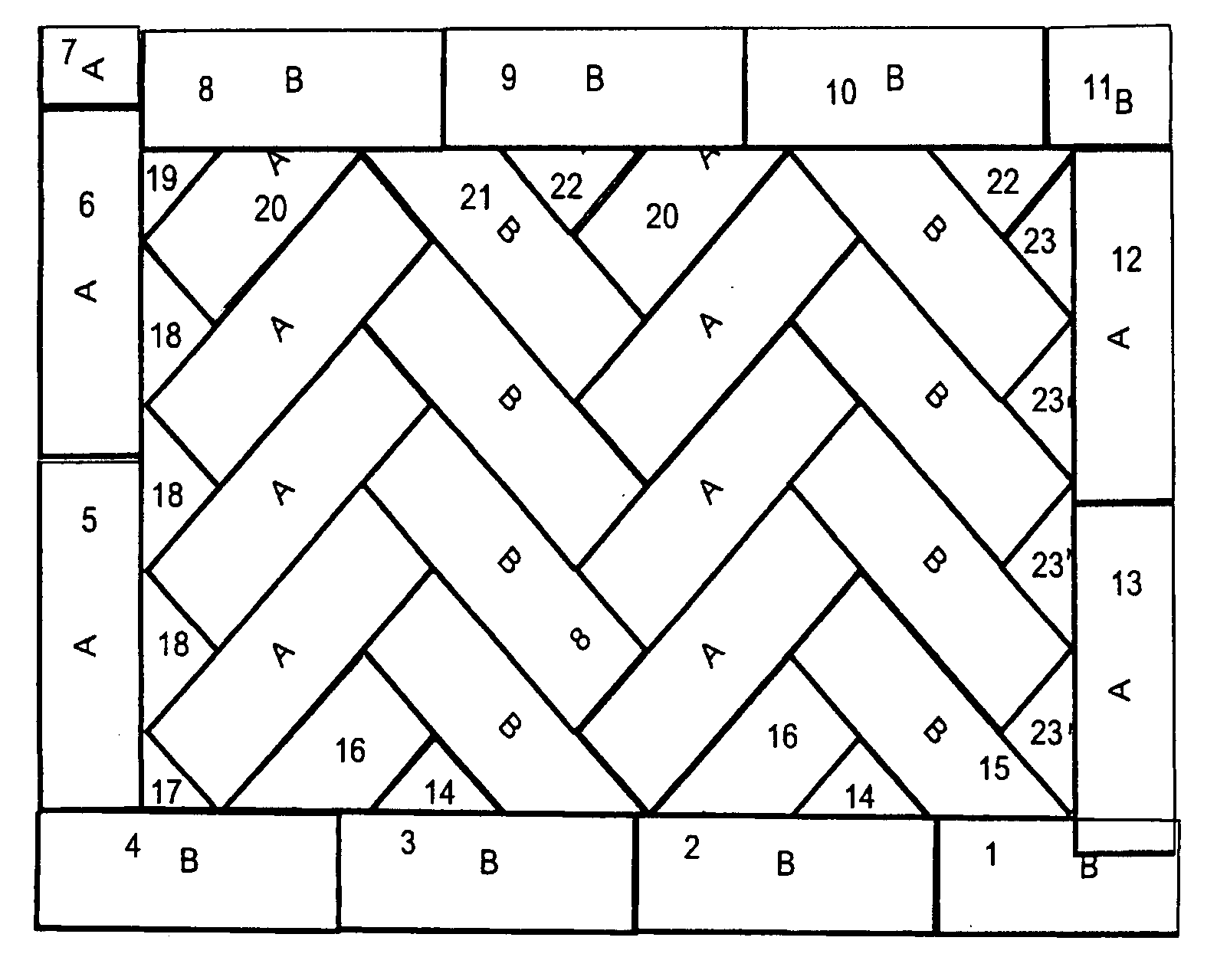

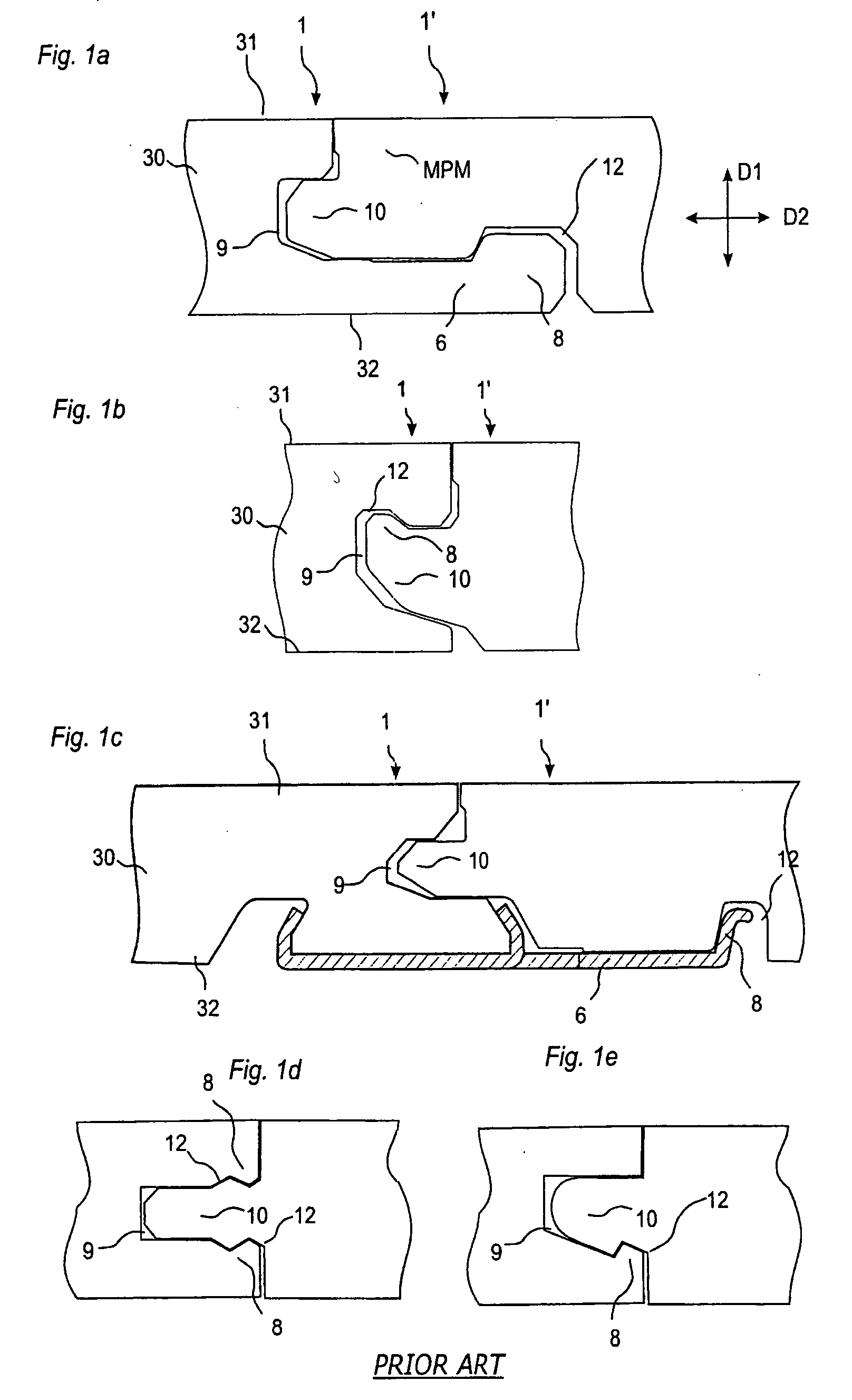

InactiveUS20060075713A1The process is simple and fastImprove distributionStrutsConstruction materialEngineeringHerringbone pattern

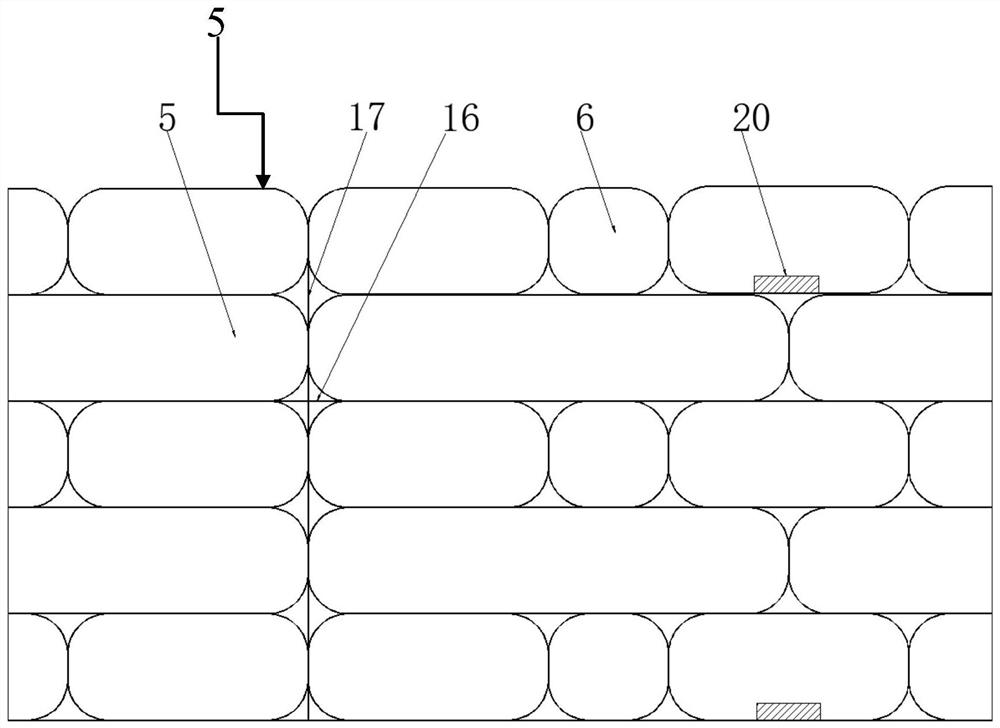

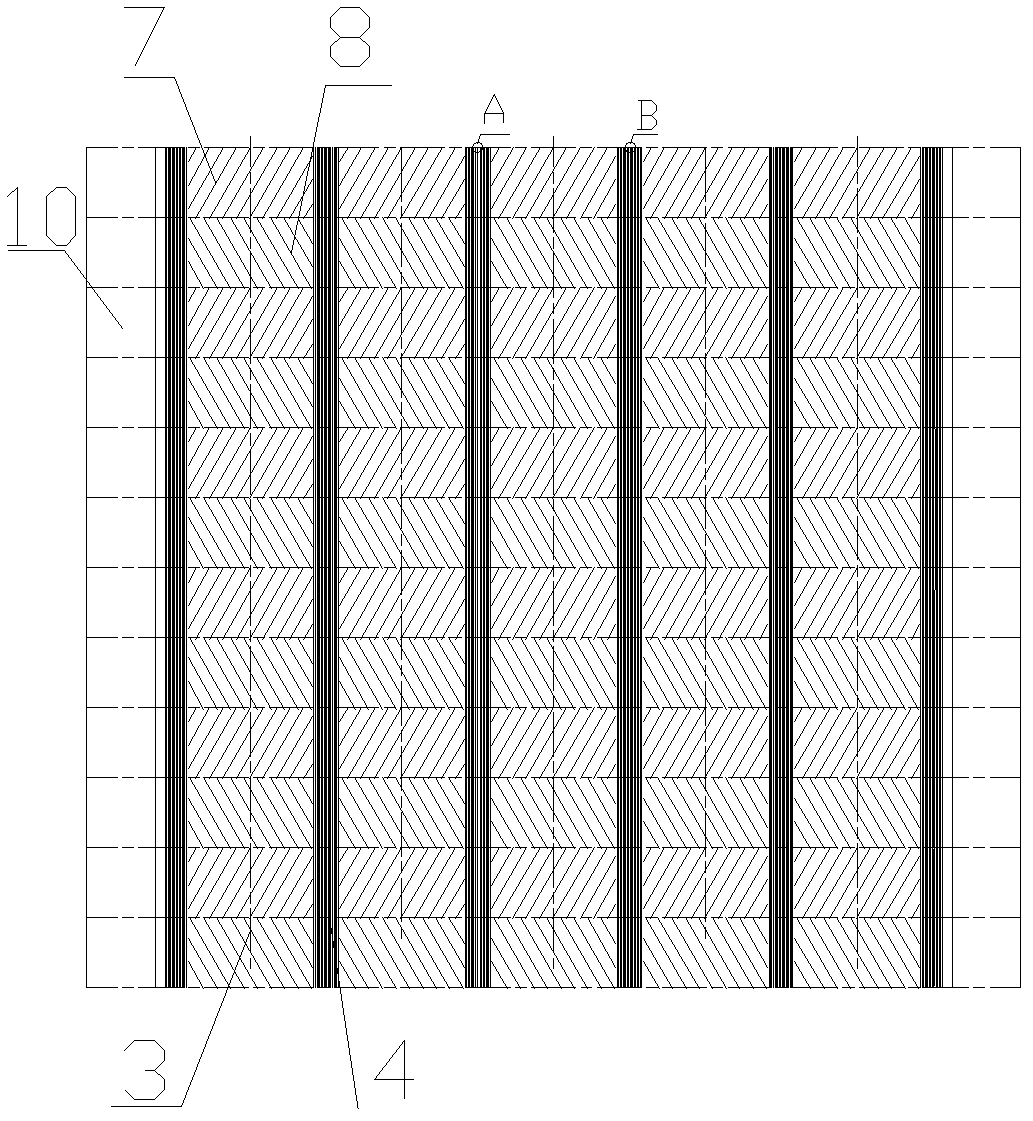

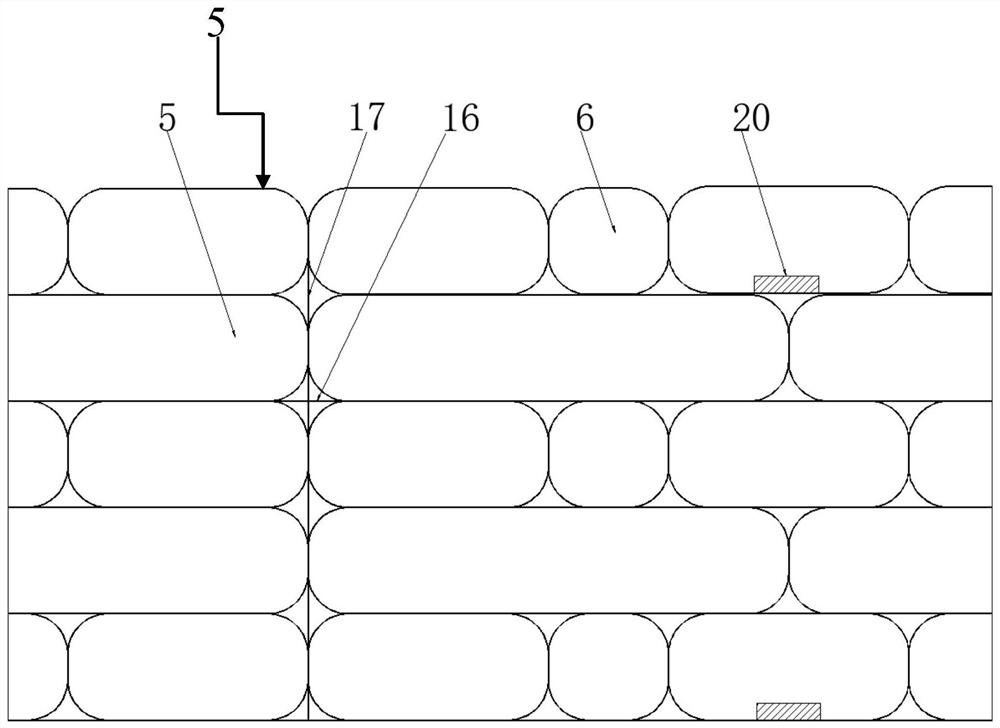

Floorboards for installation of floors in herringbone pattern are formed with two opposite sides inverted relative to each other. The invention further comprises methods for producing and making floorings comprising such floorboards, as well as fitting pieces and sets of parts for such floorings.

Owner:VÄLINGE INNOVATION AB

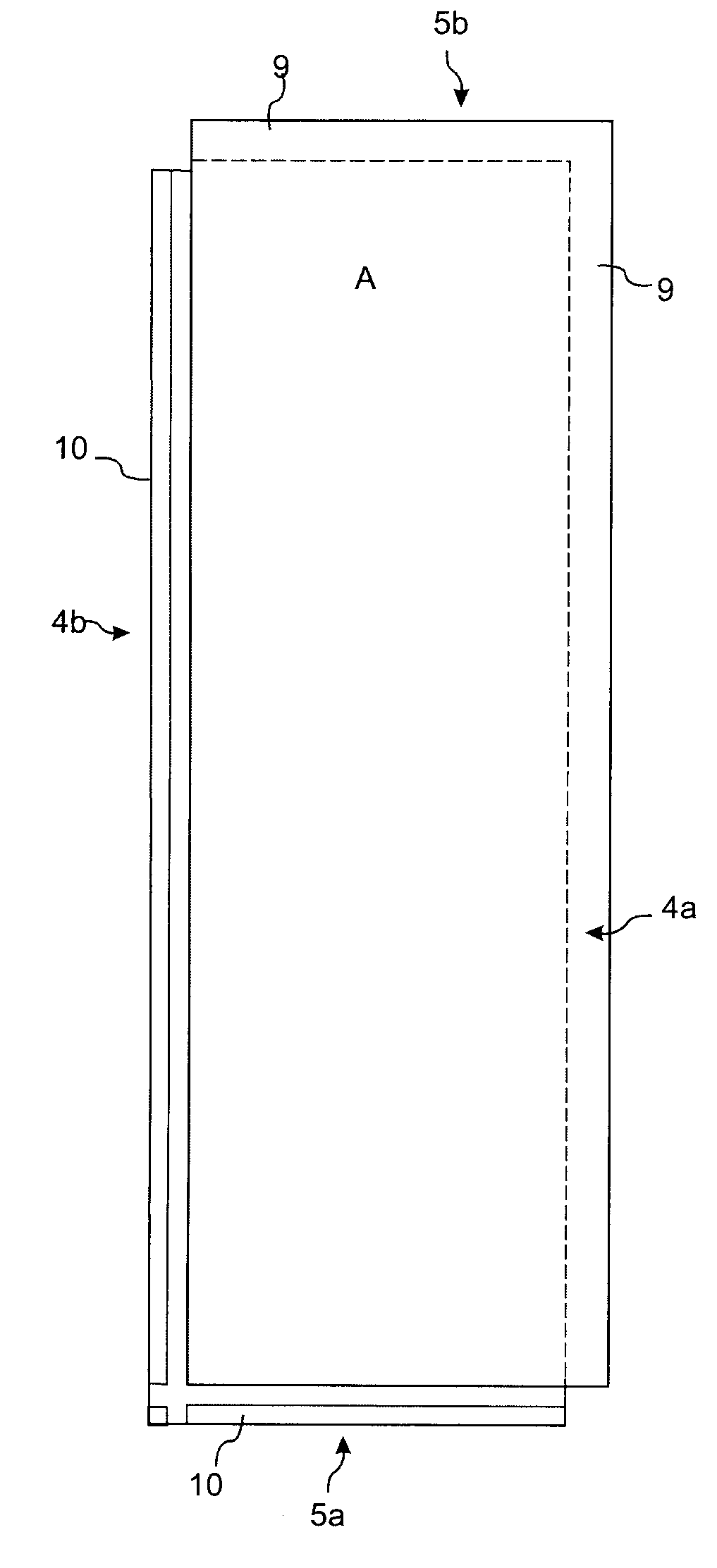

Flooring and method for laying and manufacturing the same

InactiveUS20080028713A1Improve distributionQuick and efficient layingConstruction materialWallsEngineeringHerringbone pattern

A flooring includes rectangular floorboards with long sides and short sides, the floorboards being joined in a herringbone pattern, long side to long side and long side to short side, wherein the floorboards have a surface layer of laminate, and the long sides of the floorboards have pairs of opposing mechanical connectors which at least allow locking-together both horizontally and vertically by inward angling.

Owner:VÄLINGE INNOVATION AB

Flooring And Method For Laying And Manufacturing The Same

ActiveUS20060196139A1The process is simple and fastImprove distributionStrutsConstruction materialSurface layerEngineering

A flooring includes rectangular floorboards with long sides and short sides, the floorboards being joined in a herringbone pattern, long side to long side and long side to short side, wherein the floorboards have a surface layer of laminate, and the long sides of the floorboards have pairs of opposing mechanical connectors which at least allow locking-together both horizontally and vertically by inward angling.

Owner:VÄLINGE INNOVATION AB

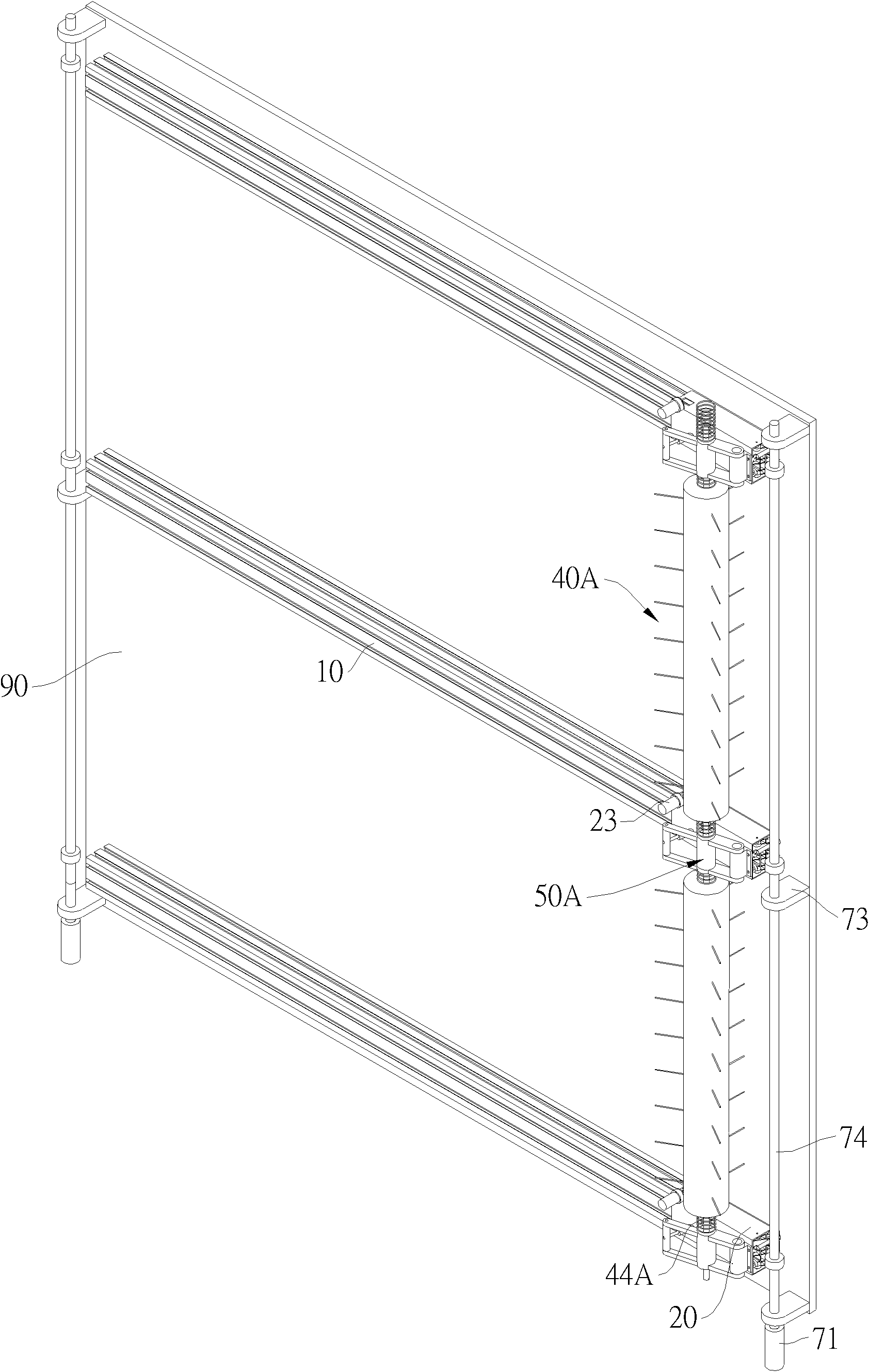

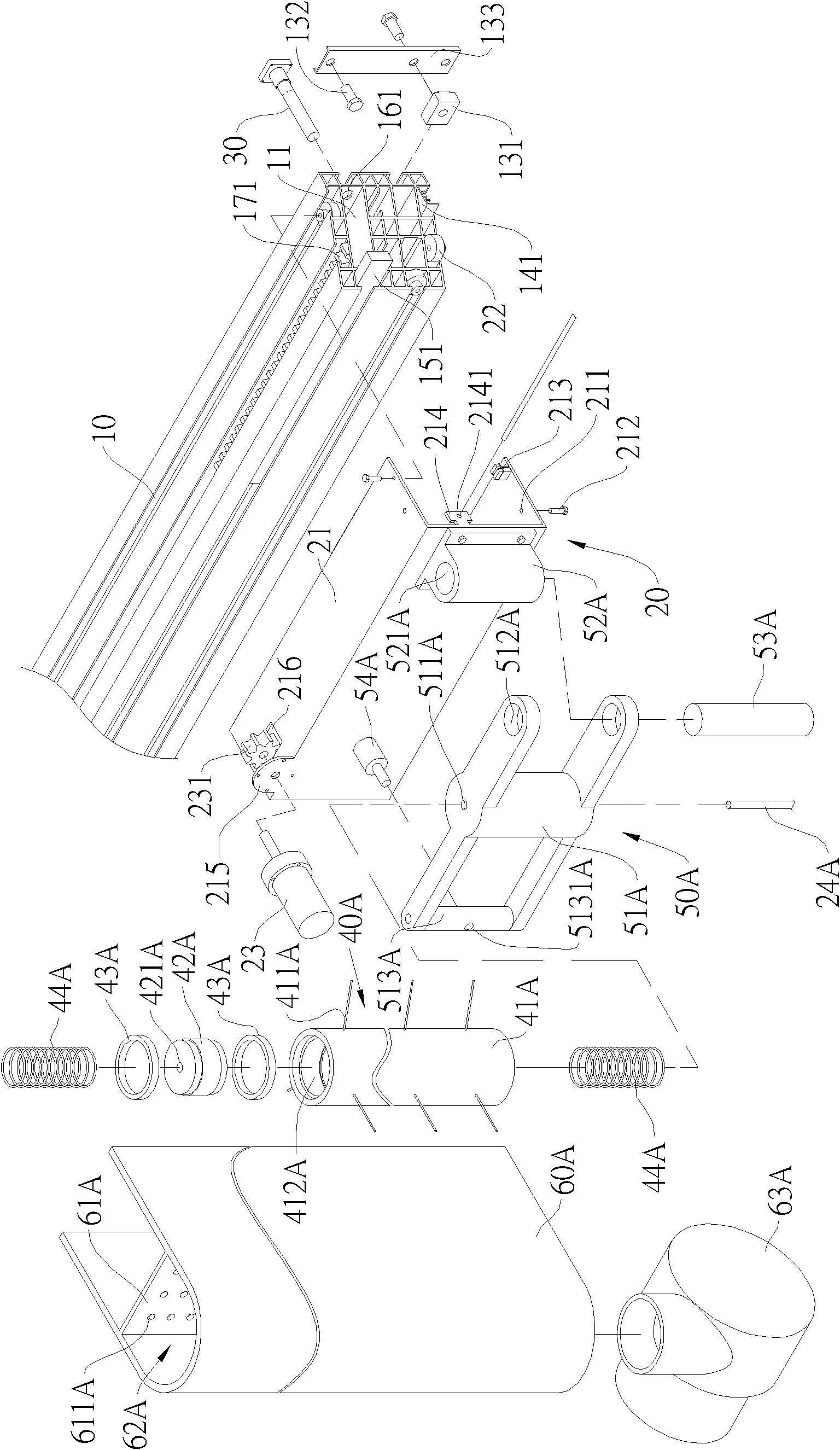

Wallboard automatic cleaning machine

InactiveCN102599864AReduce brush deformationAesthetically pleasingCarpet cleanersFloor cleanersEngineeringArray data structure

The invention relates to a wallboard automatic cleaning machine capable of cleaning the panels of exterior walls, glass or solar panels, wherein the machine is arranged on the same side with an object to be cleaned. The machine comprises a plurality of sets of parallel tracks in the long axial direction. A water conduit and electric rails are arranged on the tracks. The pipe wall of the water conduit is provided with a plurality of magnetic valves spaced from each other. A sliding engine base is arranged on the long axial tracks. A conductive frame is correspondingly arranged on the sliding engine base. The conductive frame is provided with a magnetic body in the long axial direction capable of opening or closing the cleaning water relative to the magnetic valves. A brush in the long axial direction is arranged between two adjacent sliding engine bases.

Owner:廖福彰

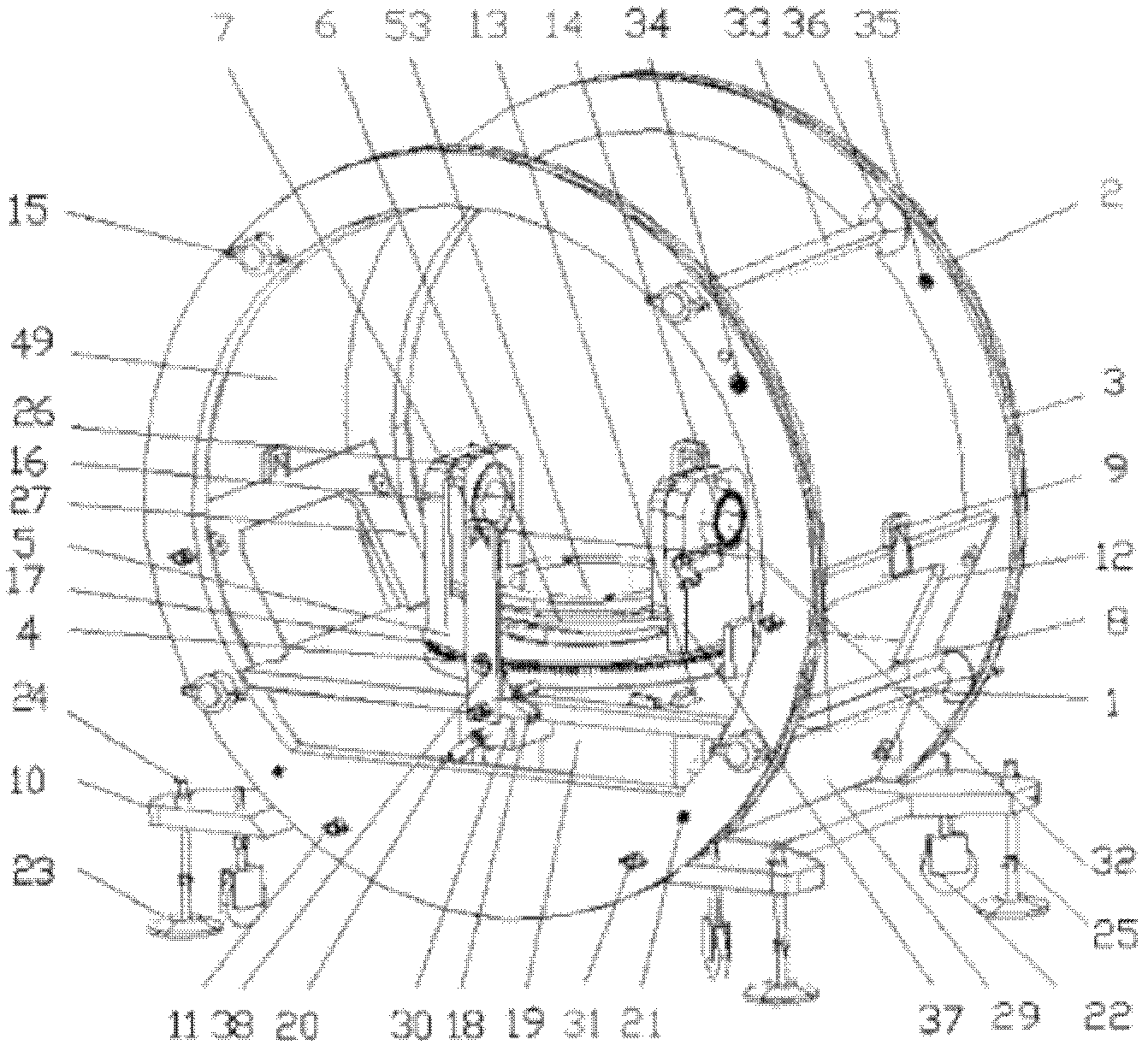

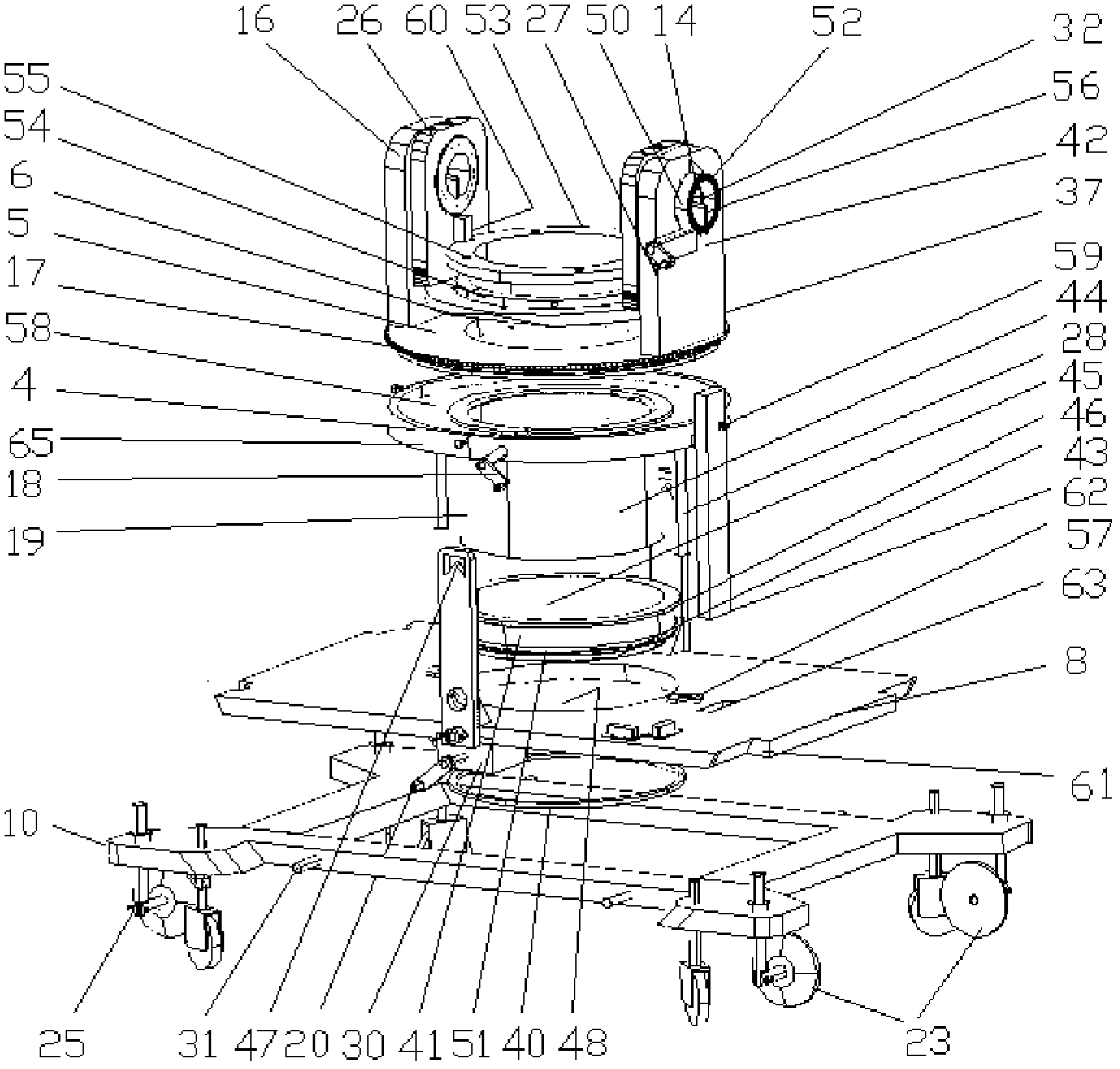

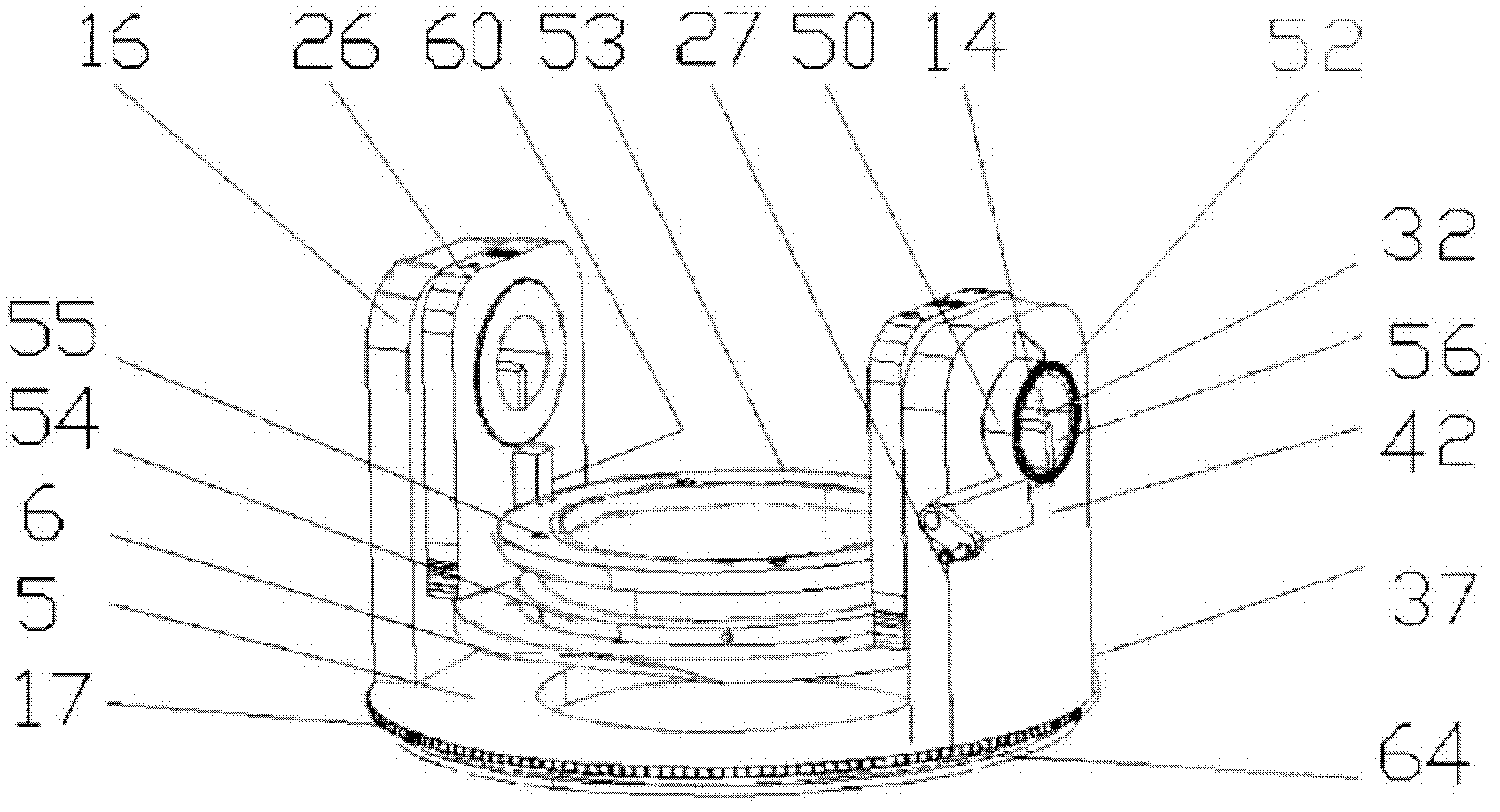

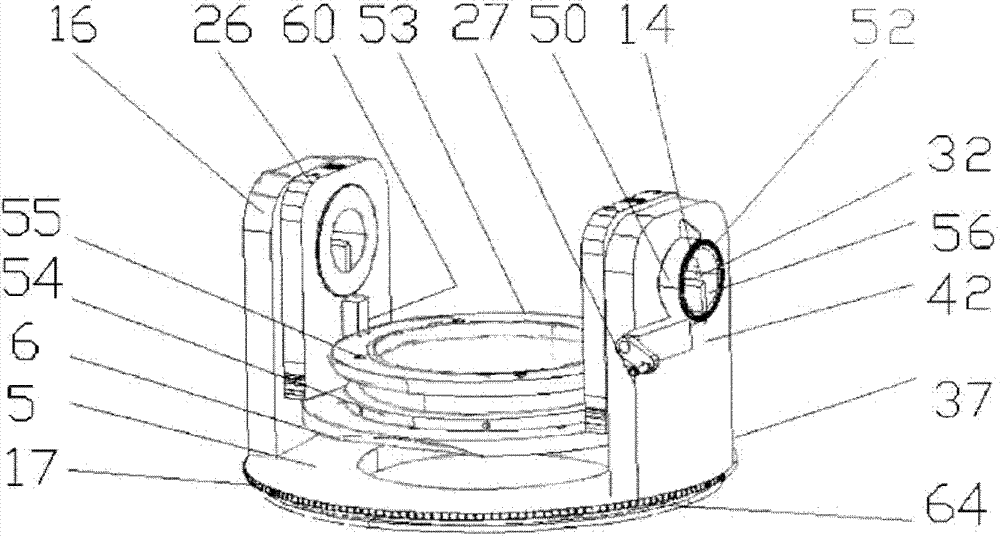

Center regulating rotary table for Helmholtz coil

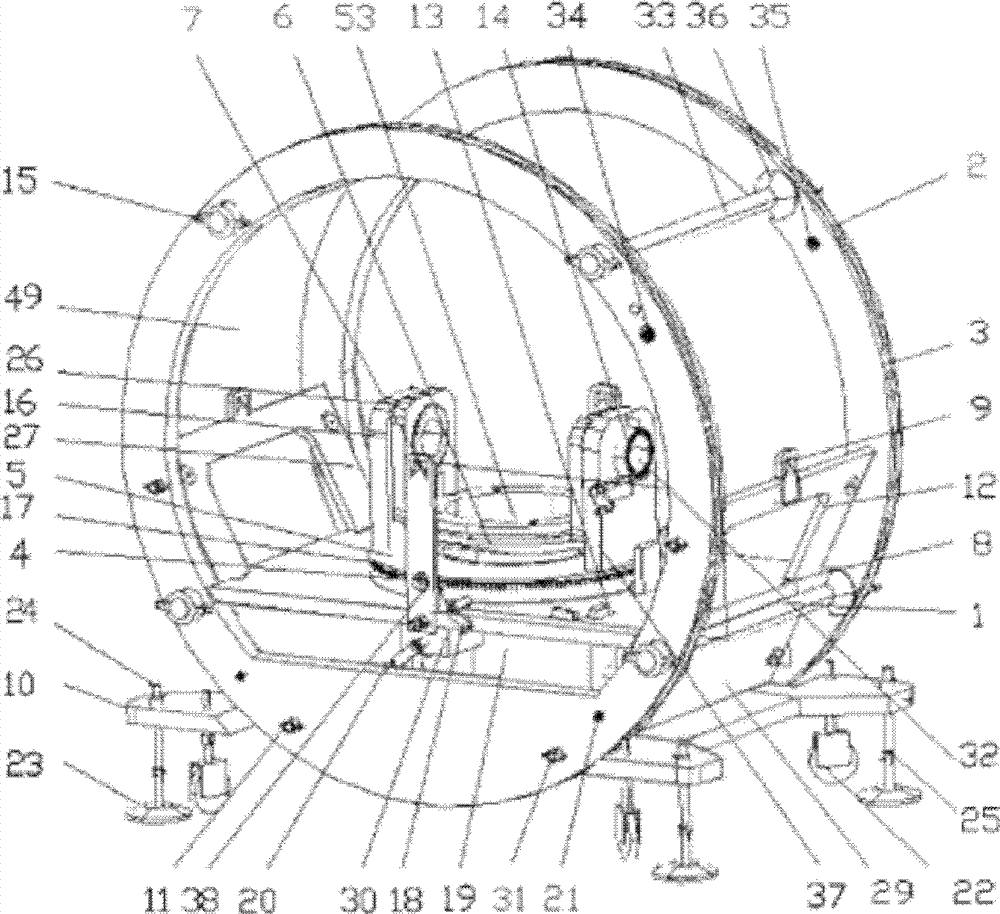

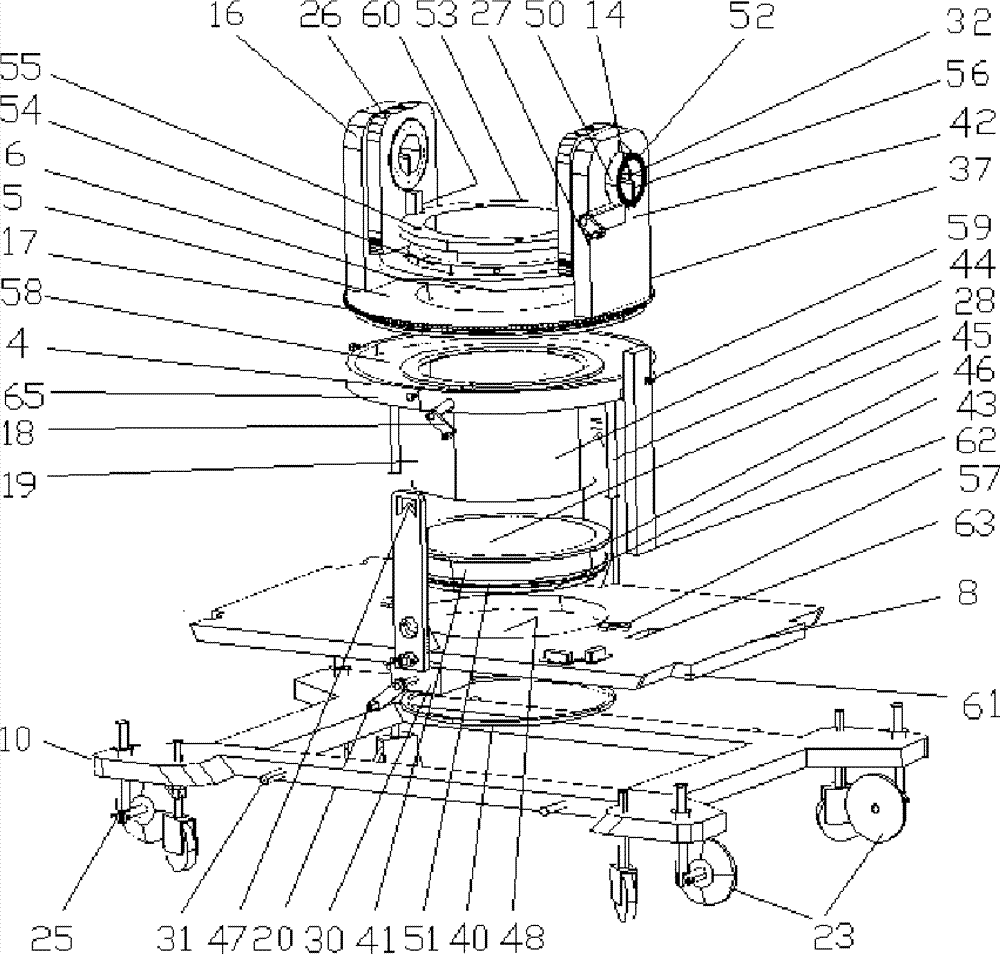

ActiveCN103048551AReasonable designEasy to assemble and disassembleElectromagentic field characteristicsHelmholtz coilEngineering

The invention relates to a center regulating rotary table for a Helmholtz coil. The device comprises a main structural frame (29) and an azimuth and lifting frame (37), wherein the main structural frame (29) comprises two circular ring-shaped plates (2) which are coaxially fixed; the circular ring-shaped plates (2) are provided with semicircular holes (49); the peripheral ring-shaped surfaces of the circular ring-shaped plates (2) are provided with grooves around the whole peripheries; the coil is wound in the grooves; the azimuth and lifting frame comprises a height regulating unit, a horizontal azimuth regulating unit and an inclination angle regulating unit; and by the arrangement of the units, high-accuracy three-dimensional continuous regulation on the height, the azimuth of spherical coordinates and the inclination angle position is implemented. The center regulating rotary table for the Helmholtz coil has the advantages that each part of the Helmholtz coil disclosed by the invention is reasonably designed, is simple and convenient to assemble and disassemble, is easy to frequently disassemble and carry and can easily implement omnibearing high-accuracy detection; and the Helmholtz coil disclosed by the invention has field windproof design and has good outdoor use applicability and strong anti-interference performance.

Owner:NAT SPACE SCI CENT CAS

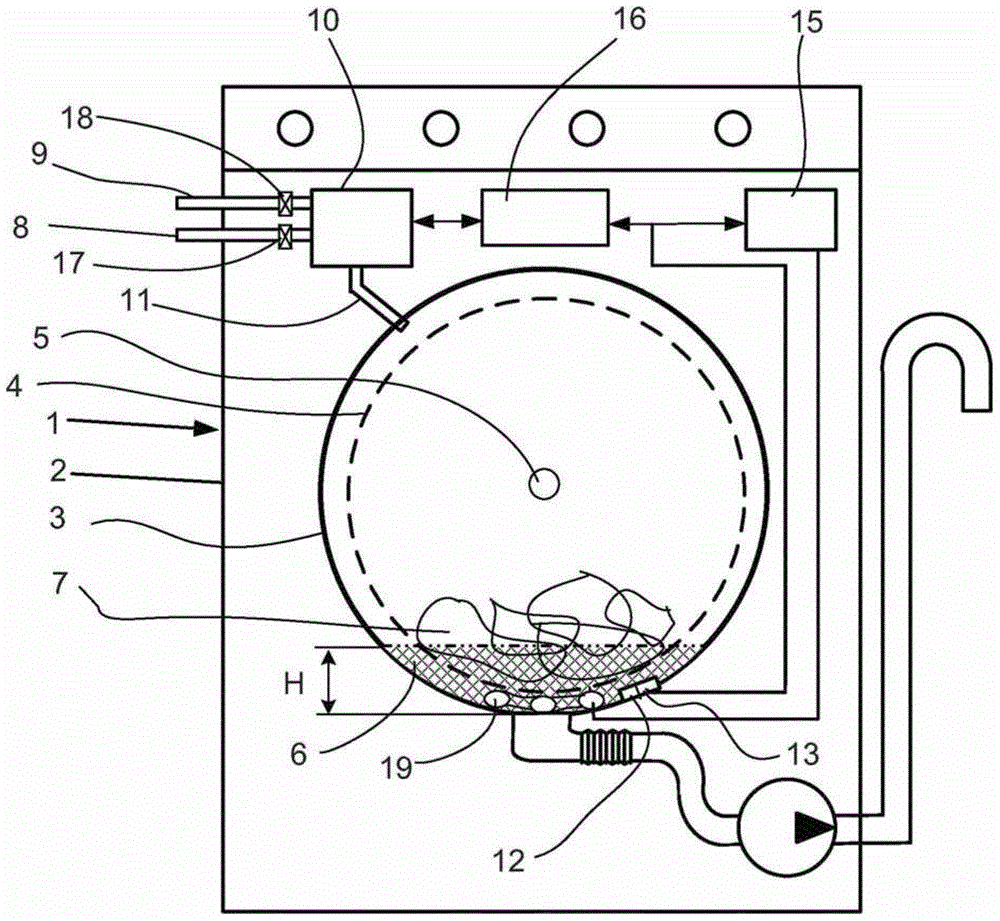

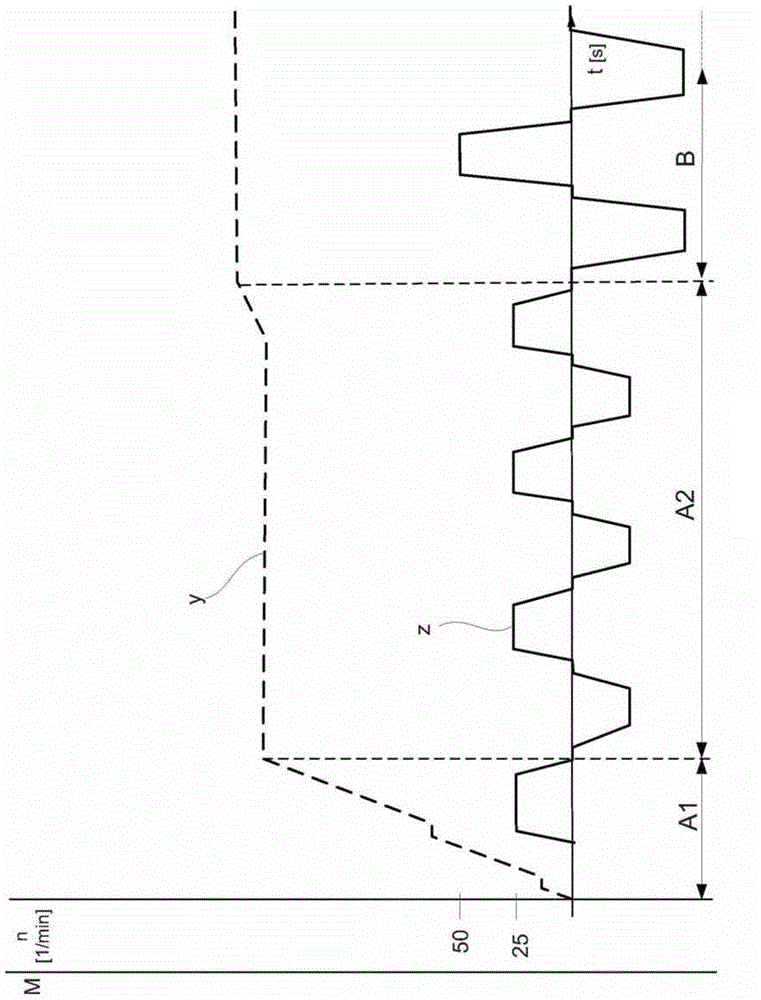

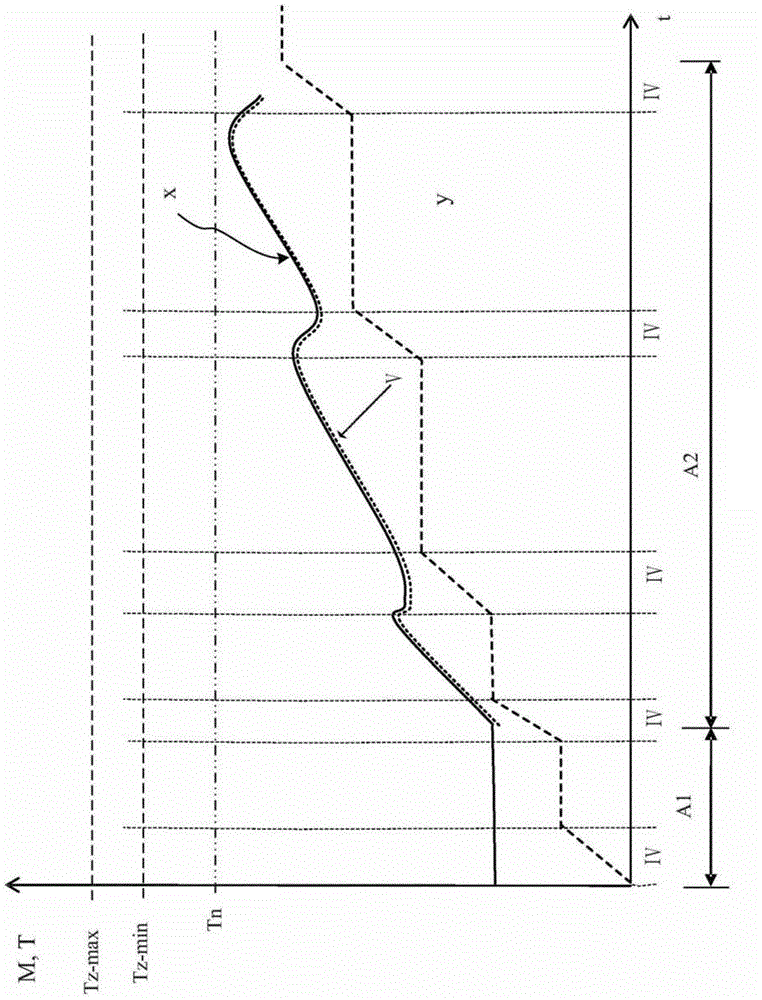

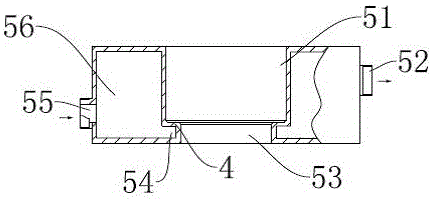

Method for washing laundry items in a program-controlled domestic appliance, and such a domestic appliance

ActiveCN104704156AGood washing temperatureImprove uniformityOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

The invention relates to a method in which a washing liquid in a suds container (3) is heated and a washing temperature of the washing liquid is set in order to wash laundry items (7) in a program-controlled domestic appliance (1) used for treating laundry items. In said method, laundry-specific and / or appliance-specific parameters, in particular the temperature of the washing liquid (6), are detected and the washing liquid is heated in dependence on the parameters in order to set a specific target temperature. The method is characterized in that, during a wetting phase (A2), in which washing liquid (6) is fed to the suds container (3) in order to wet the laundry items (7), a heating device (16) included in the domestic appliance is activated in order to heat the washing liquid (6), and the washing liquid (6) is heated by means of the heating device (16) to a wetting-phase temperature (Tn) that is lower than the target temperature (Tz) that is associated with a washing method selected by an operator. The method preferably also comprises a hot-water controller which causes the washing liquid to be heated to the target temperature during the wetting phase. The invention further relates to a corresponding domestic appliance.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

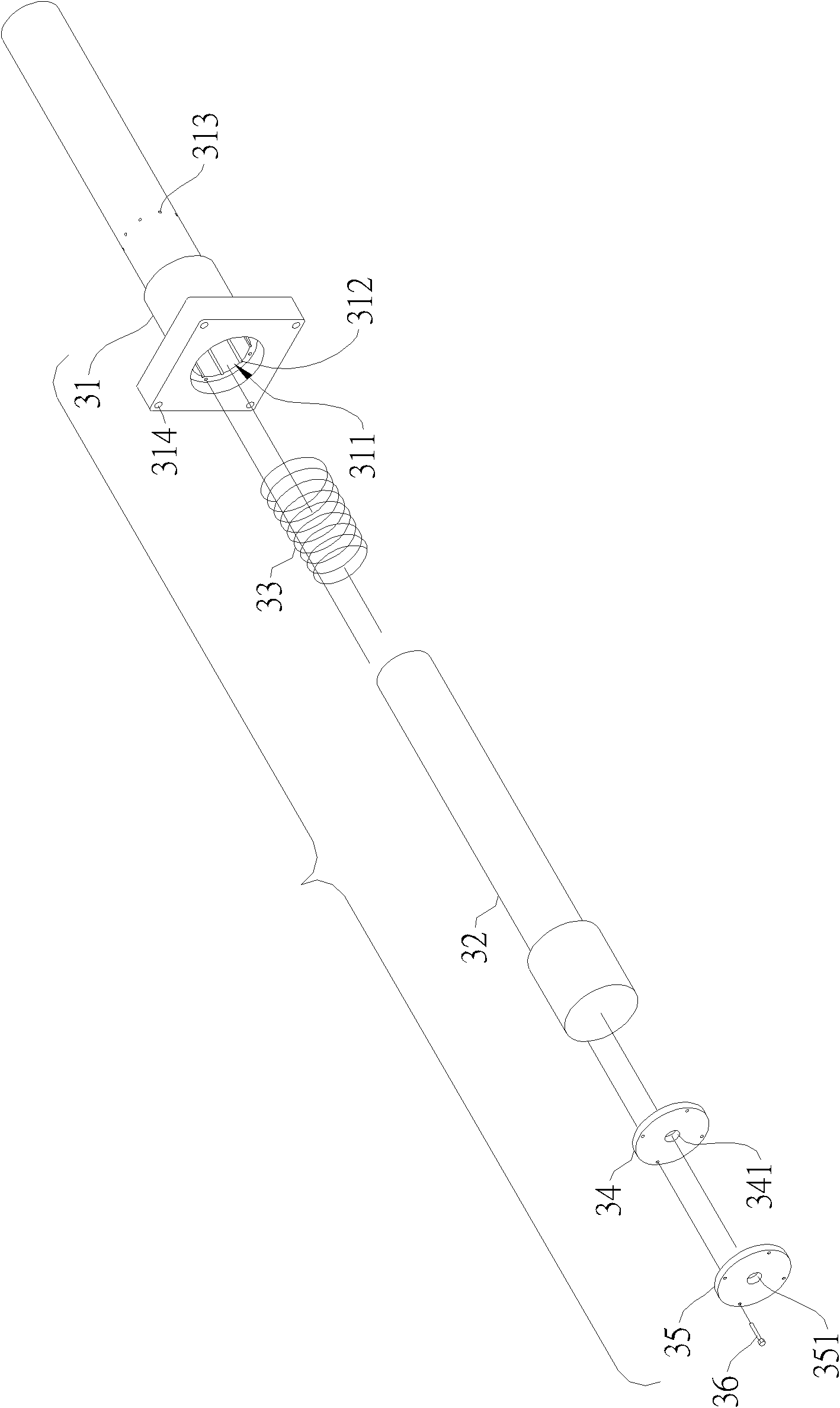

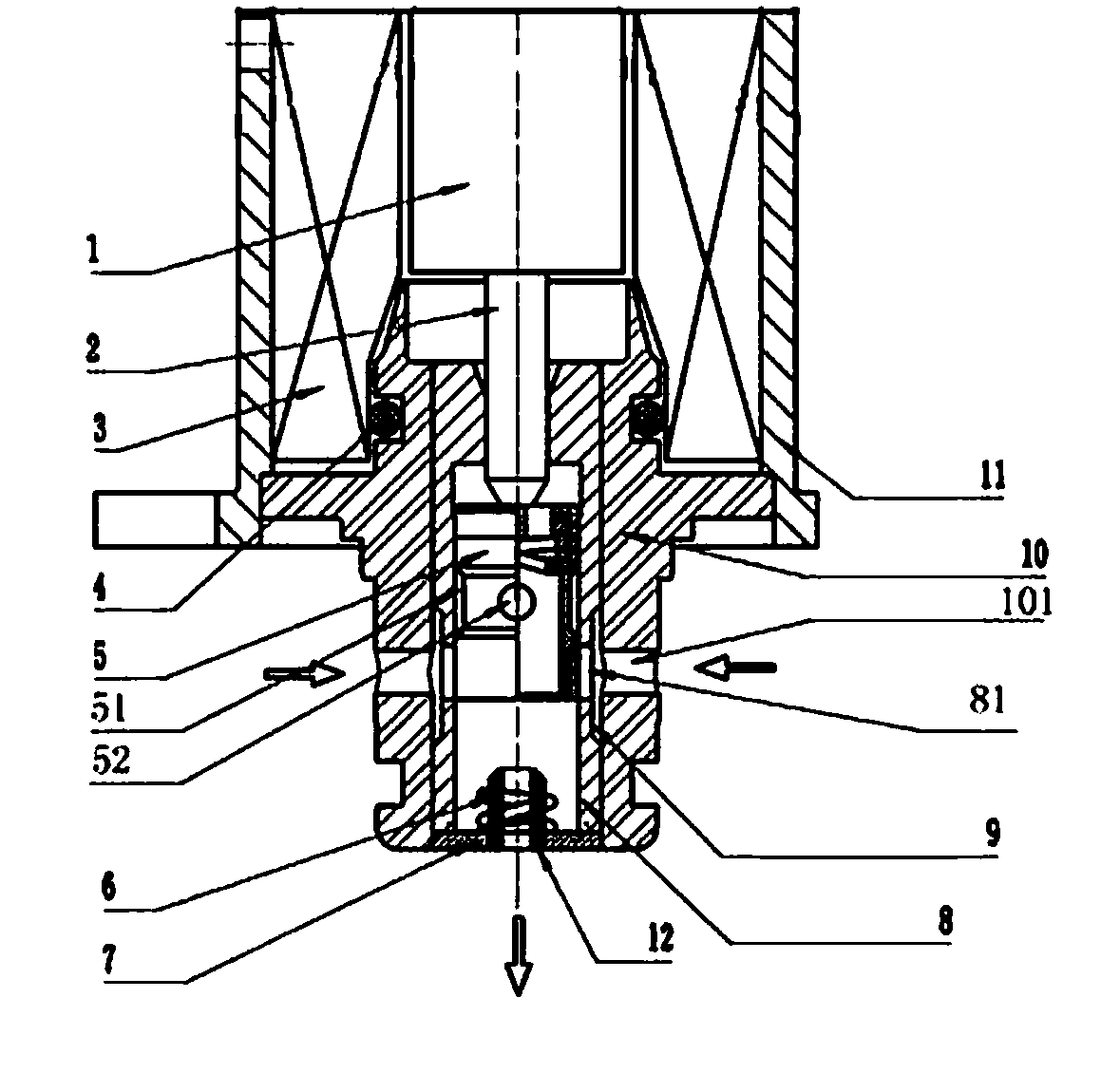

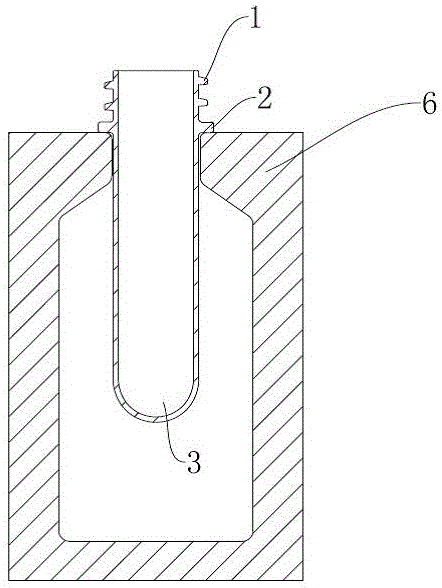

Proportional value adjustable high pressure common rail proportional electromagnetic valve

InactiveCN104315231AChange the stiffnessChange the scale valueOperating means/releasing devices for valvesSlide valveInterference fitCommon rail

The invention relates to a proportional value adjustable high pressure common rail proportional electromagnetic valve. The proportional value adjustable high pressure common rail proportional electromagnetic valve comprises a valve seat and a valve casing; a coil and an armature are arranged in the valve casing; a valve core is arranged in the valve seat; a piston is arranged in the valve core; an ejector rod is arranged in a coil chamber; one end of the ejector rod is in interference fit with the armature; the other end of the ejector rod penetrates a hole to be in contact with the bottom surface of the piston, wherein the hole is formed at the tail end of the valve core; the circumferential direction of the valve seat is provided with a first inlet hole; a second inlet hole is formed in the circumferential direction of the valve core corresponding to the first inlet hole; the circumferential direction of the piston is provided with an annular groove; the circumferential direction of the annular groove is provided with a flow hole which is communicated with an inner chamber of the piston to enable the second inlet hole which is formed in the valve core to be blocked through the circumferential direction outside the annular groove of the piston. The proportional value adjustable high pressure common rail proportional electromagnetic valve is characterized in that one end of the valve seat, which is far away from the valve casing, is in in interference fit with a spring seat; the center of the spring seat is provided with a screw hole; an adjustment screw is arranged in the screw hole; a spring is arranged in the piston; one end of the spring abuts against the inner bottom of the piston and the other end of the spring abuts against the spring seat; the inner end of the adjustment screw extends into the spring. The proportional value adjustable high pressure common rail proportional electromagnetic valve can be applied to different specifications of oil pumps and is suitable for a high pressure common rail system of a diesel engine.

Owner:无锡正大轴承机械制造股份有限公司

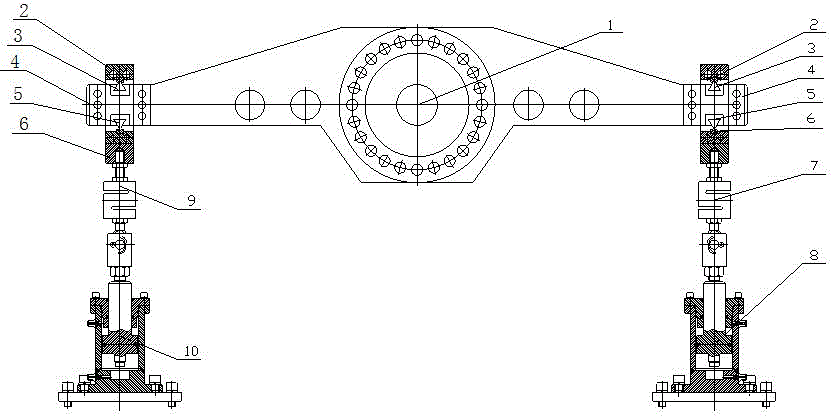

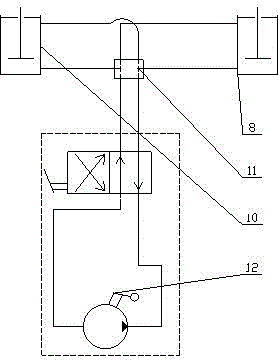

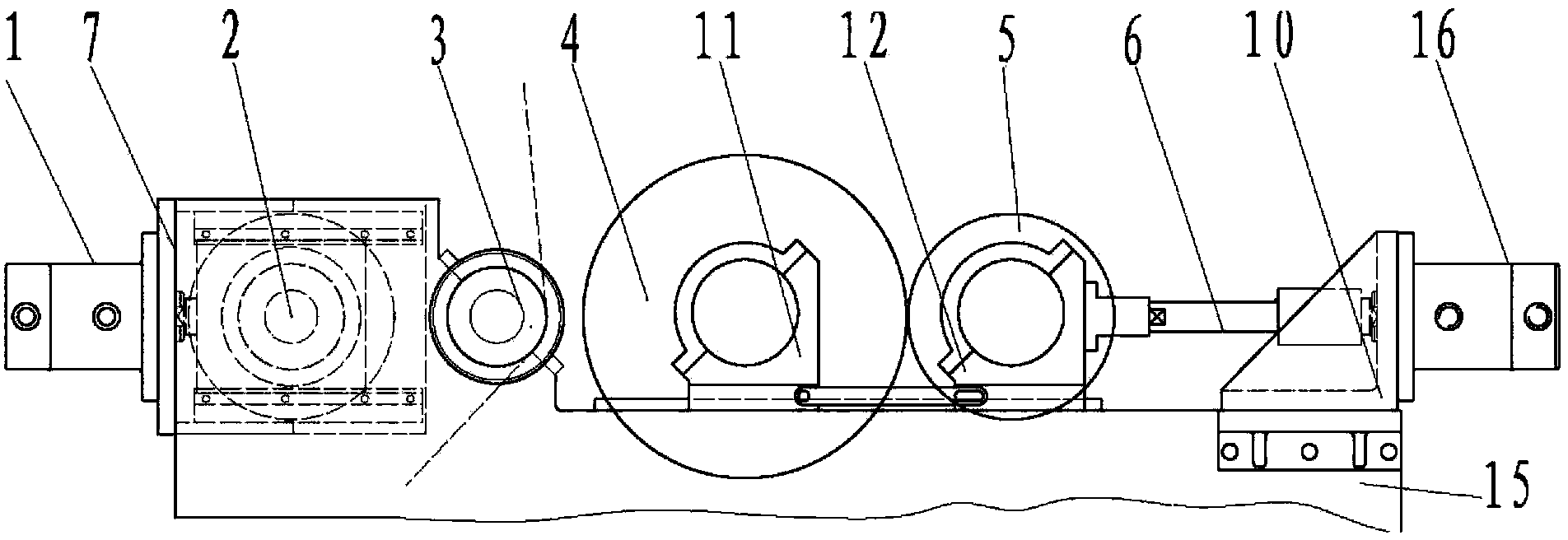

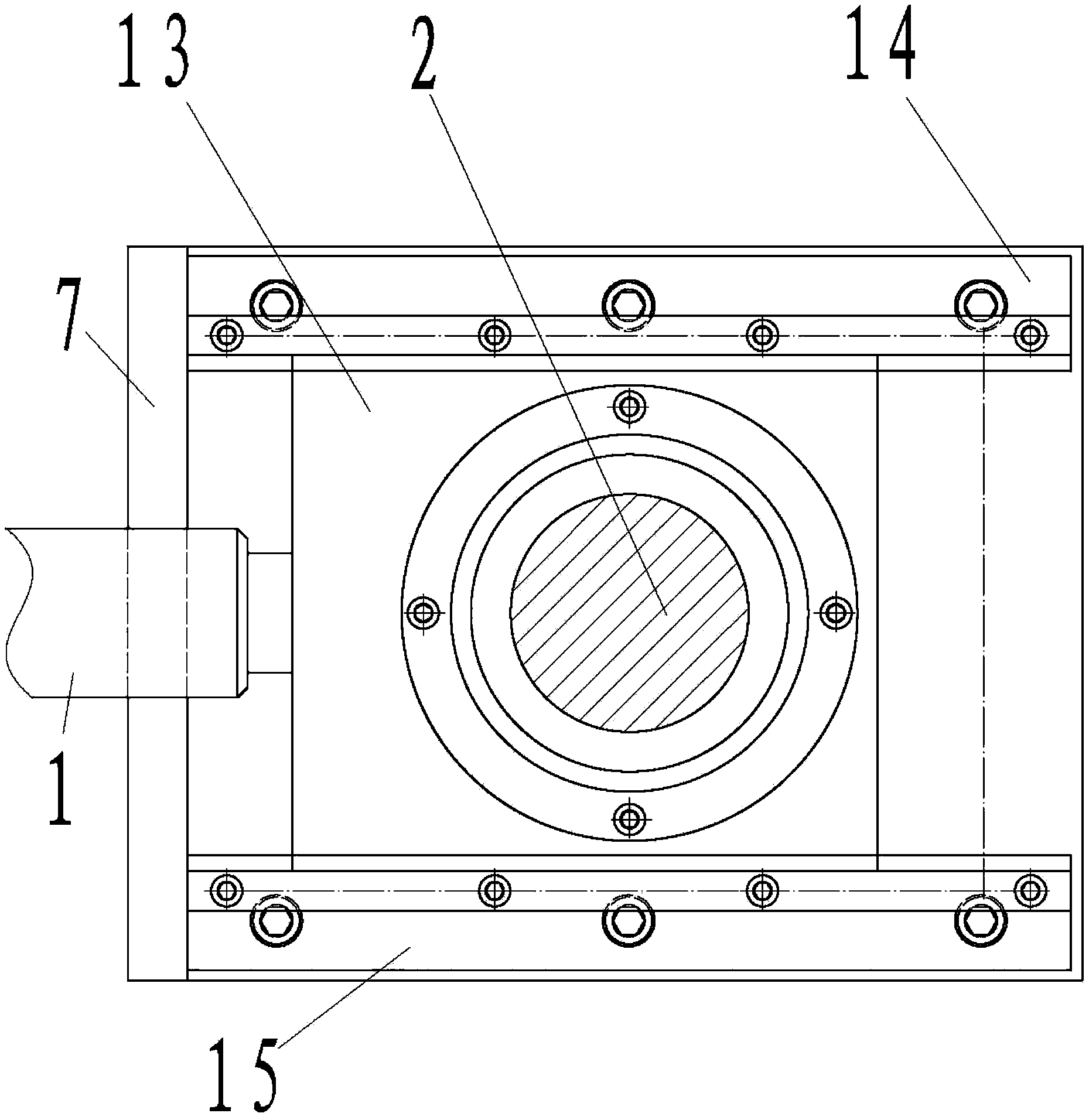

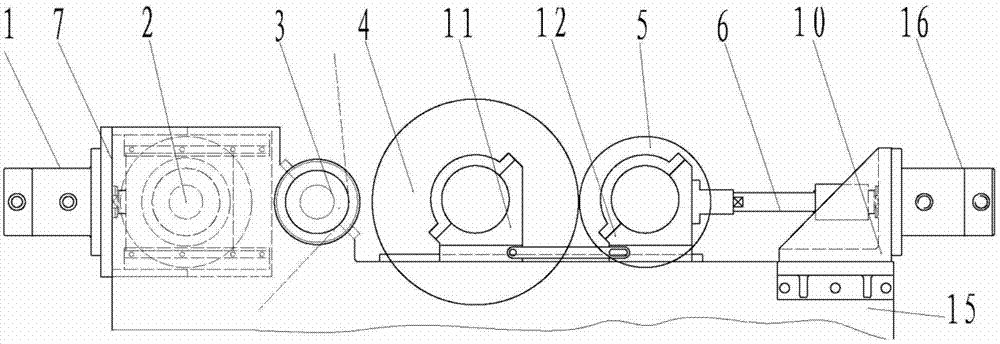

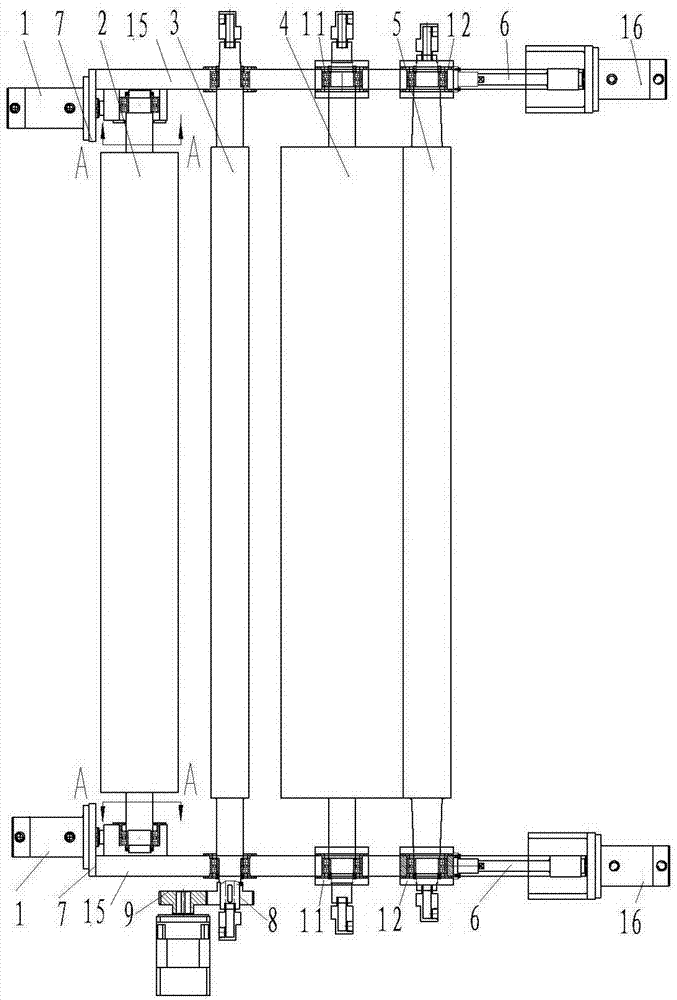

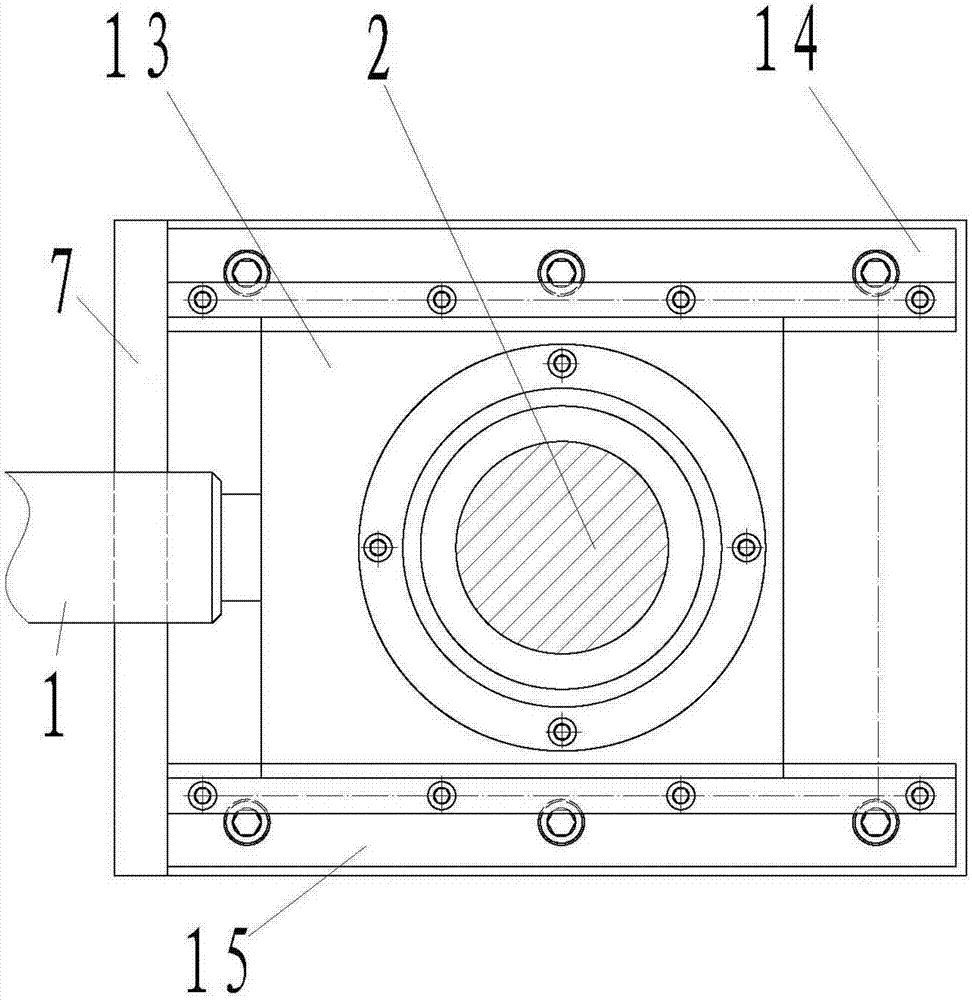

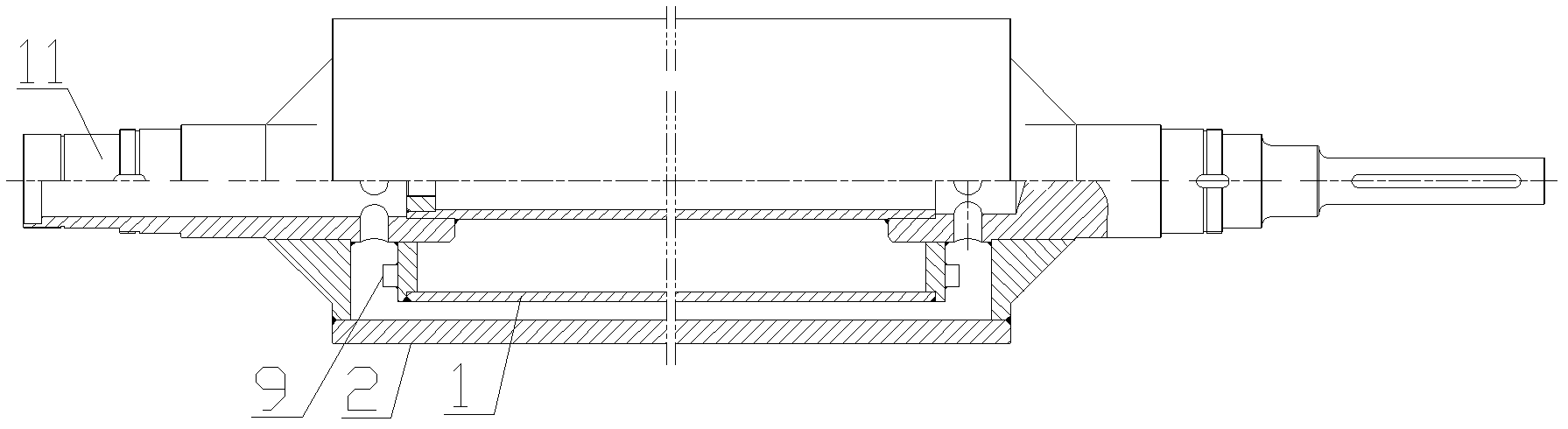

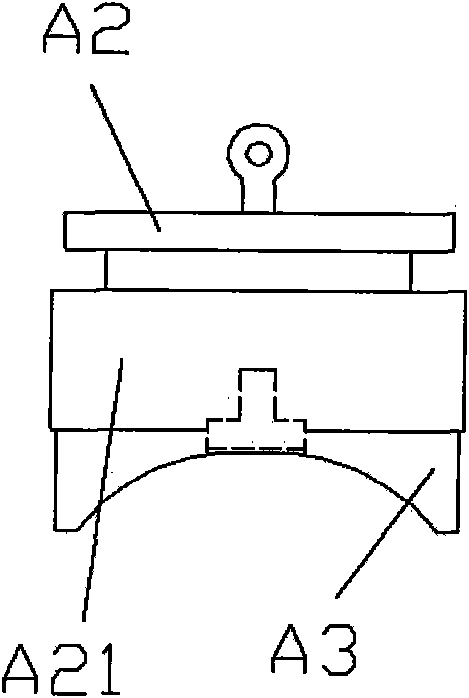

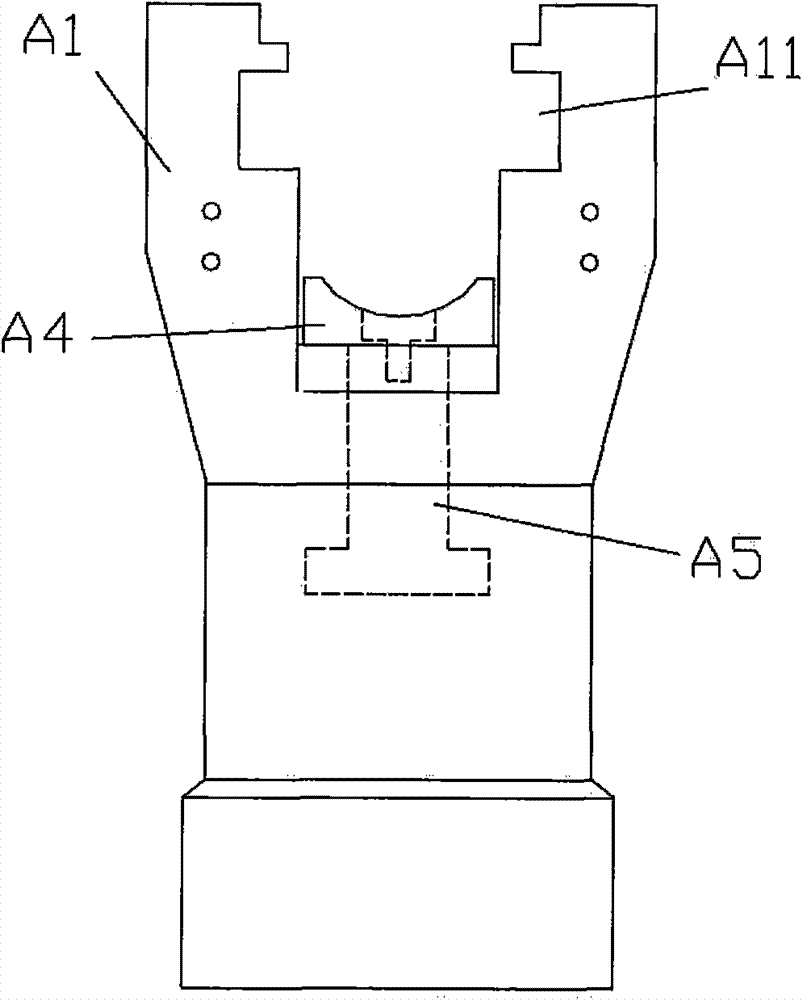

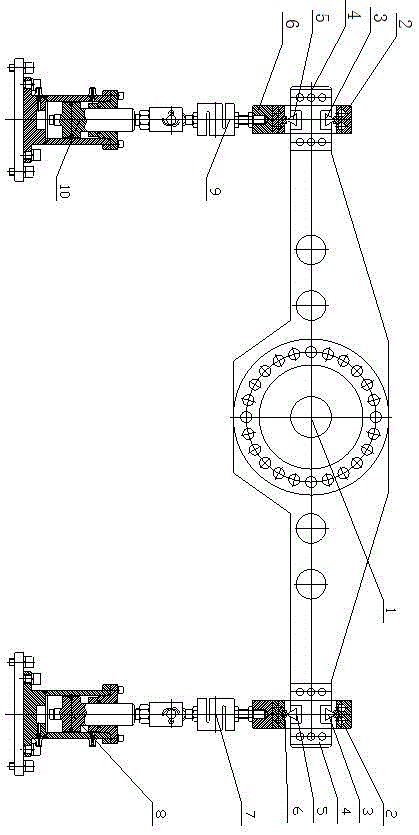

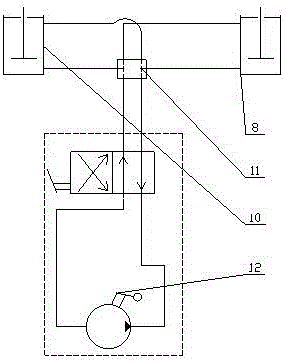

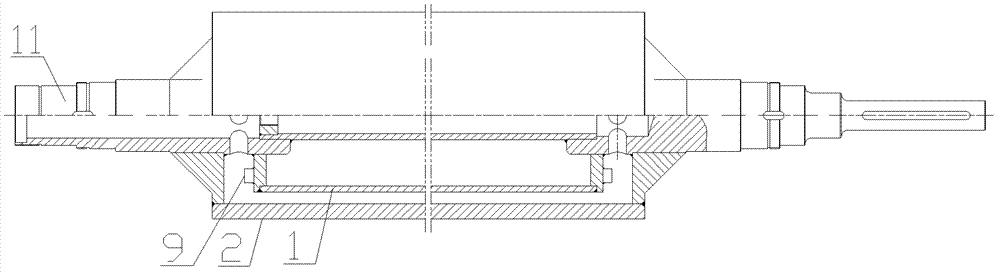

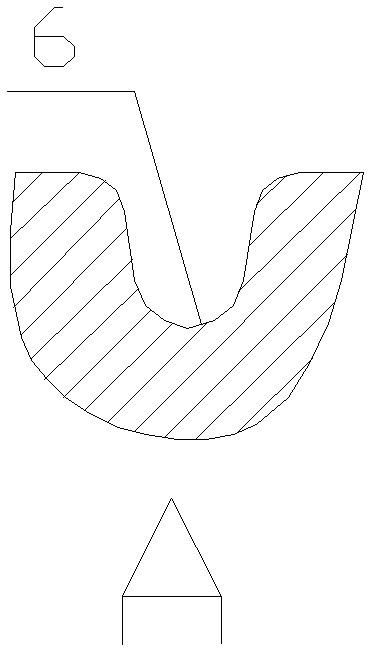

Hydraulic balance loading large torque static calibration device

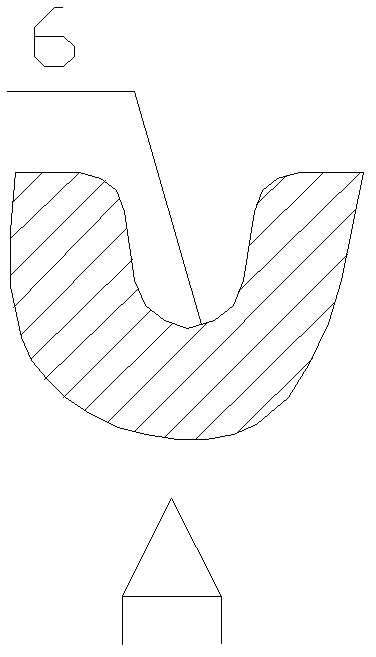

ActiveCN104155053AHigh precisionReduce variantForce/torque/work measurement apparatus calibration/testingControl theoryFrictional resistance

The invention discloses a hydraulic balance loading large torque static calibration device which comprises a torquemeter main shaft. Both ends of the torquemeter main shaft are symmetrically and fixedly connected with correction arms. Upper and lower ends of each correction arm are respectively connected with an upper triangular knife and a lower triangular knife. Each upper triangular knife is connected with an upper V-shaped block. Each lower triangular knife is connected with a lower V-shaped block. The lower part of a lower V-shaped block is provided with a first pull and press sensor and a first cylinder. The lower part of a lower V-shaped block on the other end is provided with a second pull and press sensor and a second cylinder. According to the invention, the left first cylinder is used to carry out balance loading; pulling and pressing are carried out at the same time; the torquemeter main shaft only bears torque, but does not bear a radial force; deformation is reduced; frictional resistance is reduced; and the static calibration precision is improved.

Owner:南通常测机电设备有限公司

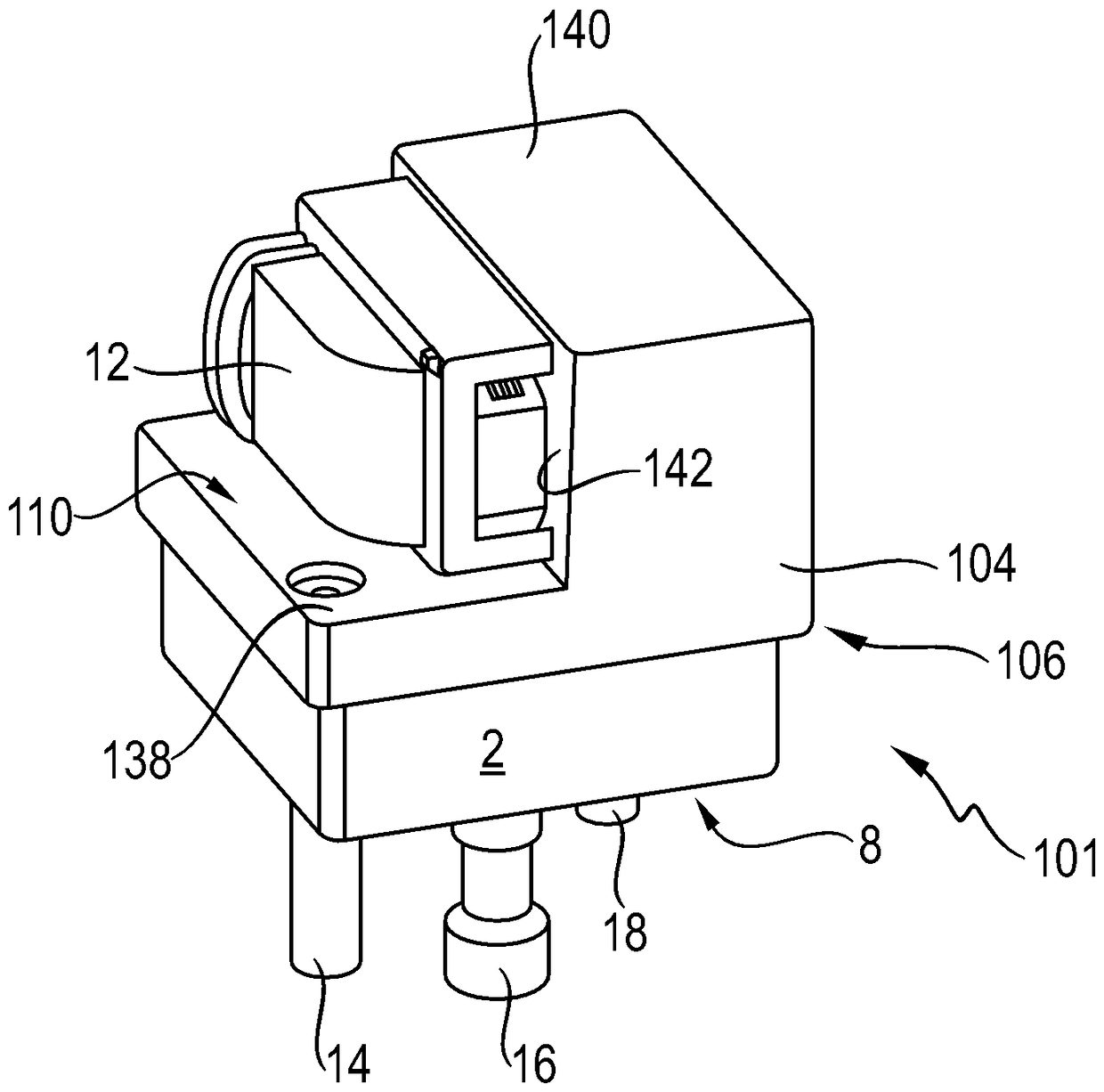

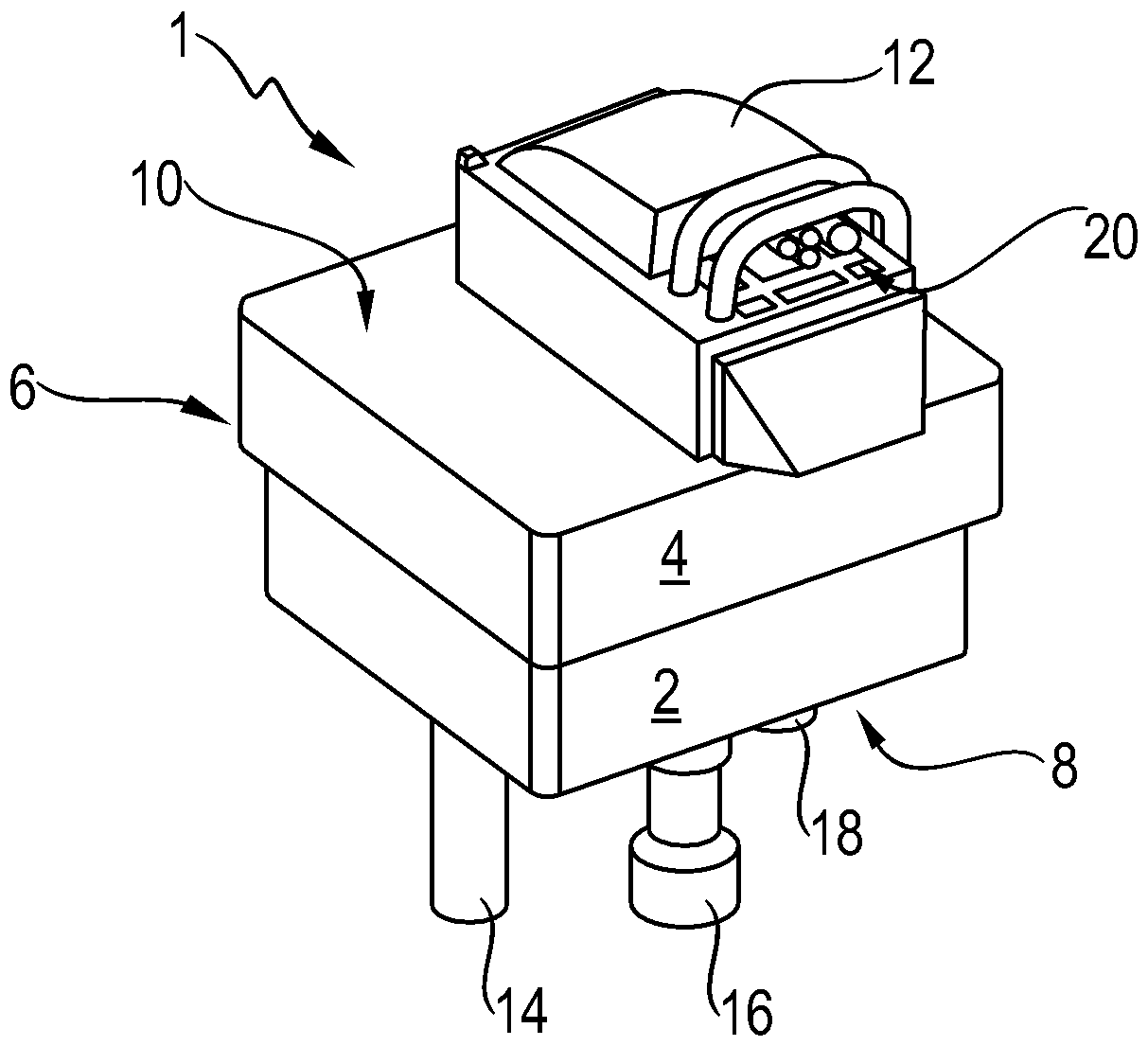

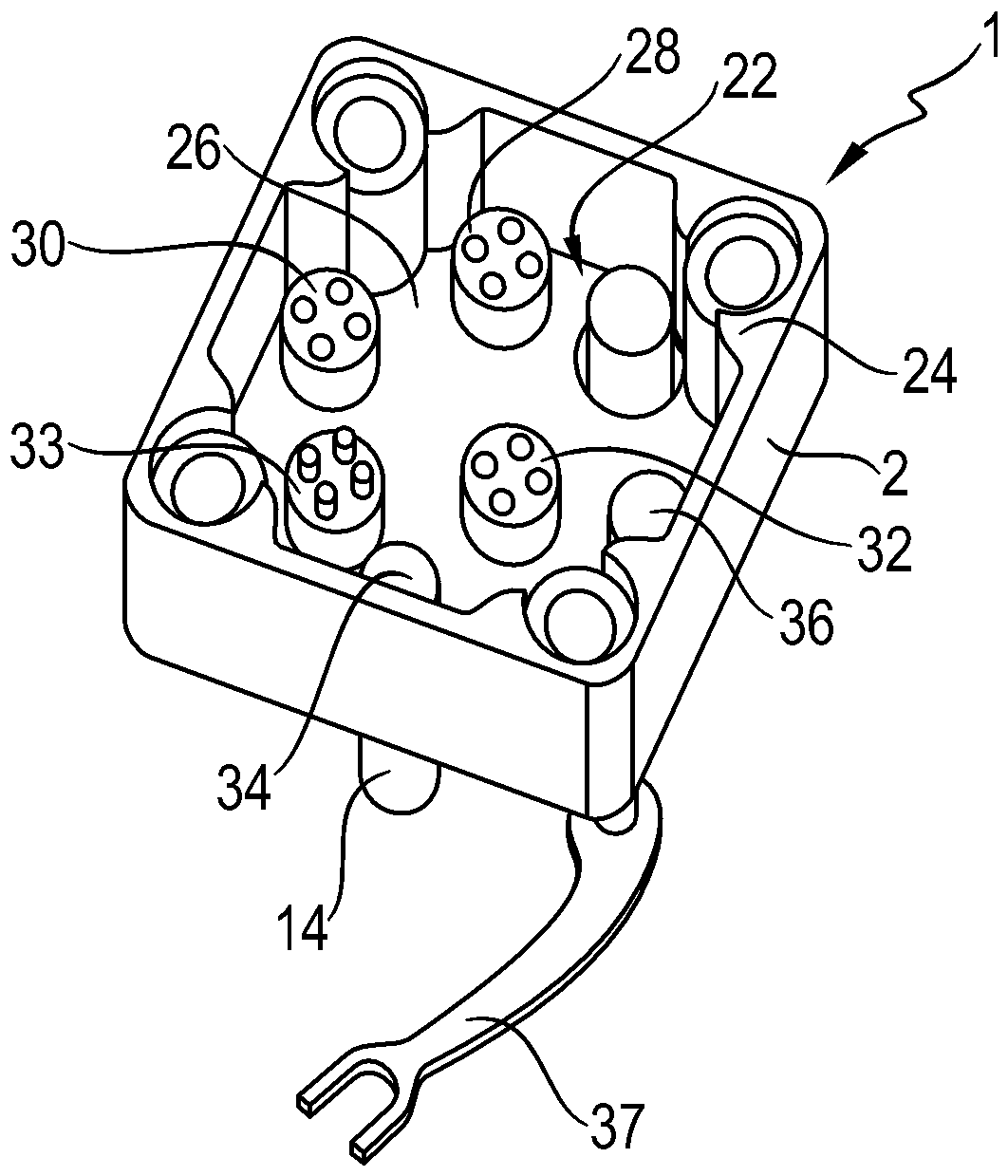

Spindle apparatus for use on a numerically controlled machine tool

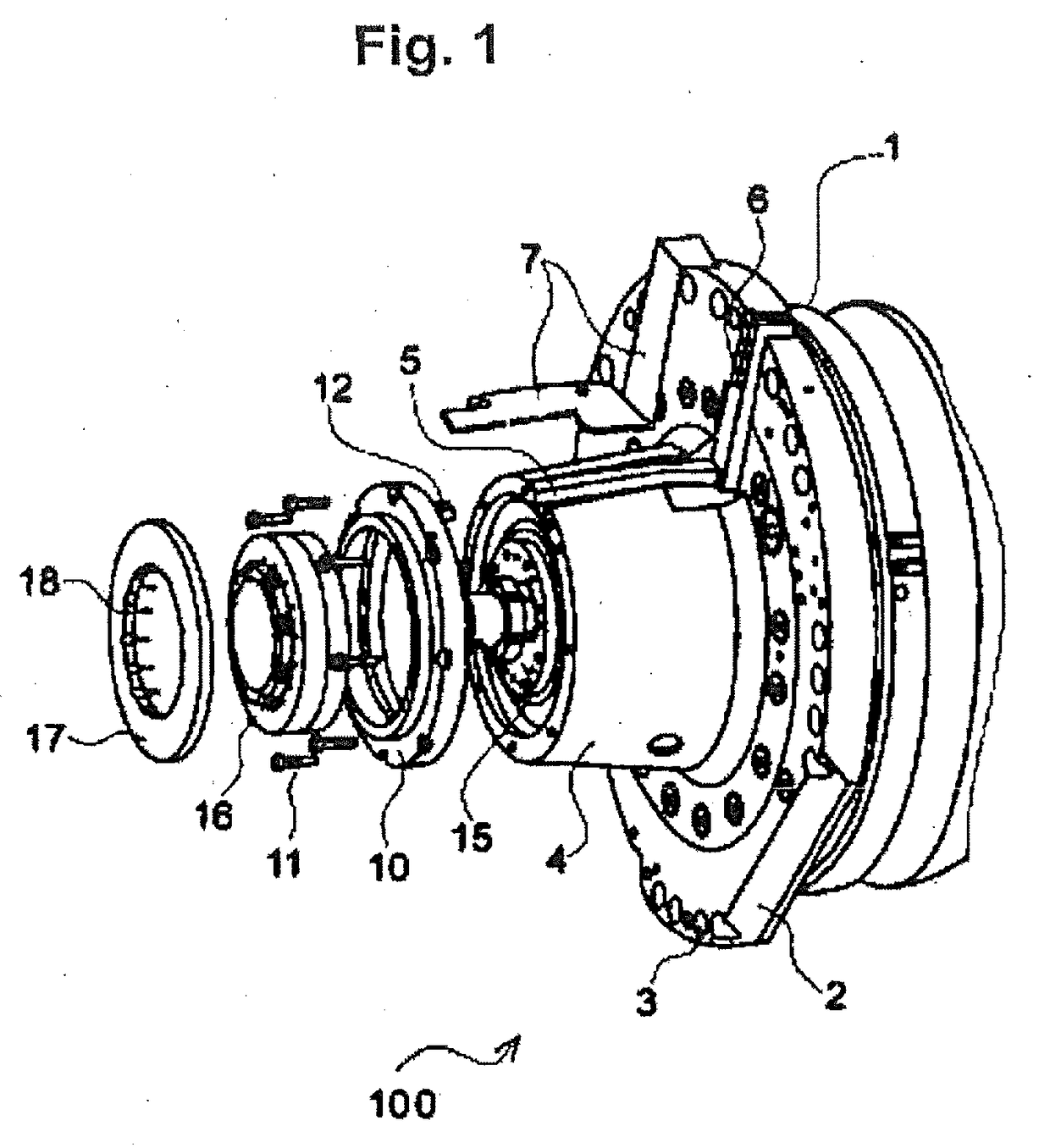

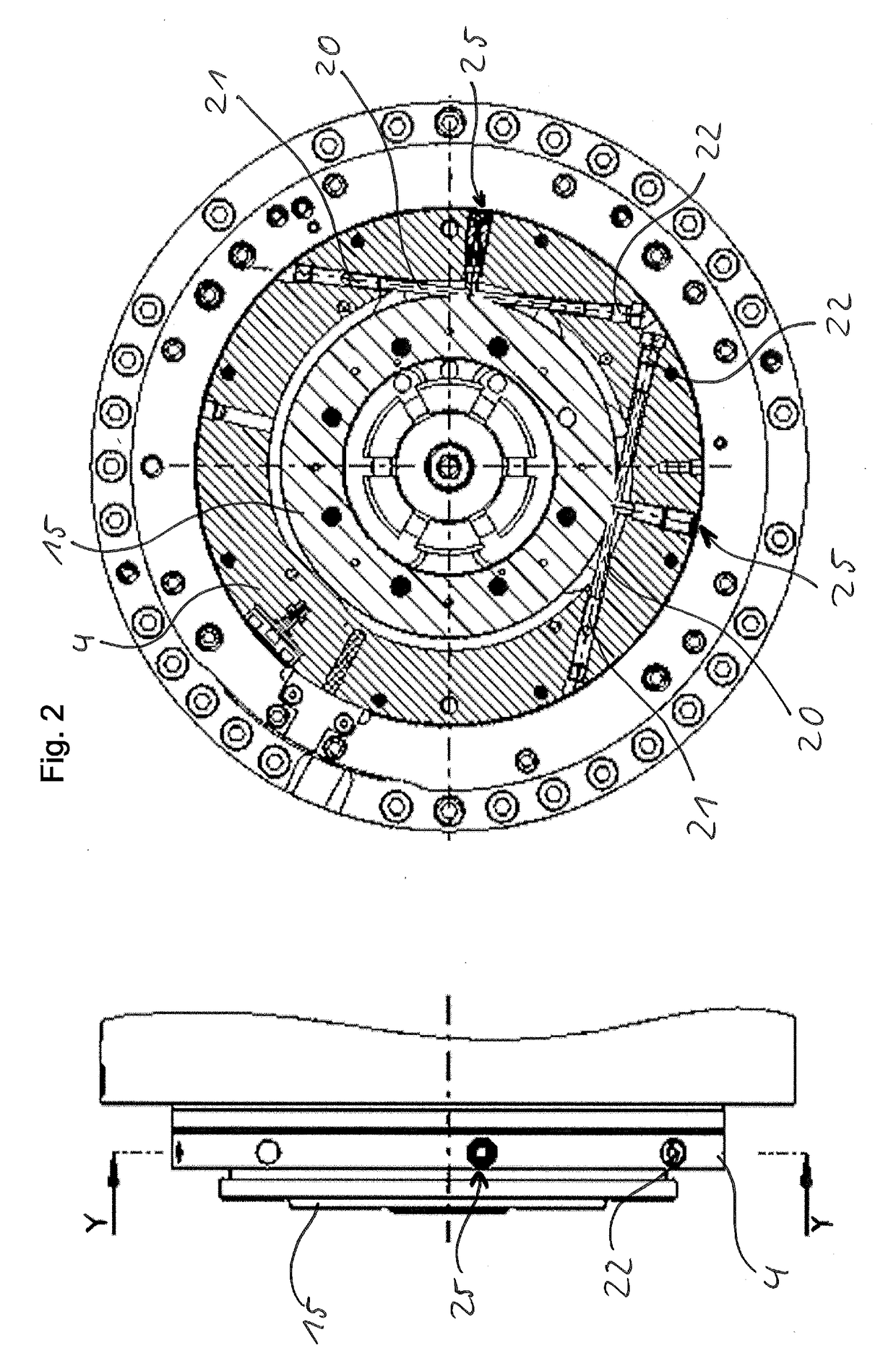

InactiveUS20190061085A1Improve machining accuracyImprove accuracyAutomatic control devicesMeasurement/indication equipmentsElectrically conductiveSpindle apparatus

The present invention relates to a spindle apparatus 100 for use on a numerically controlled machine tool, which spindle apparatus 100 has the following: a spindle housing 1, and a spindle shaft 15 which is mounted in the spindle housing, the spindle apparatus 100 having, furthermore, an electrically earthed section 4 which holds at least one rod element 20 which comprises an electrically conductive material, and the at least one rod element 20 being arranged in such a way that it makes contact with the spindle shaft 15 so as to bear tangentially against an outer circumference of the spindle shaft 15.

Owner:DECKEL MAHO PFRONTEN GMBH

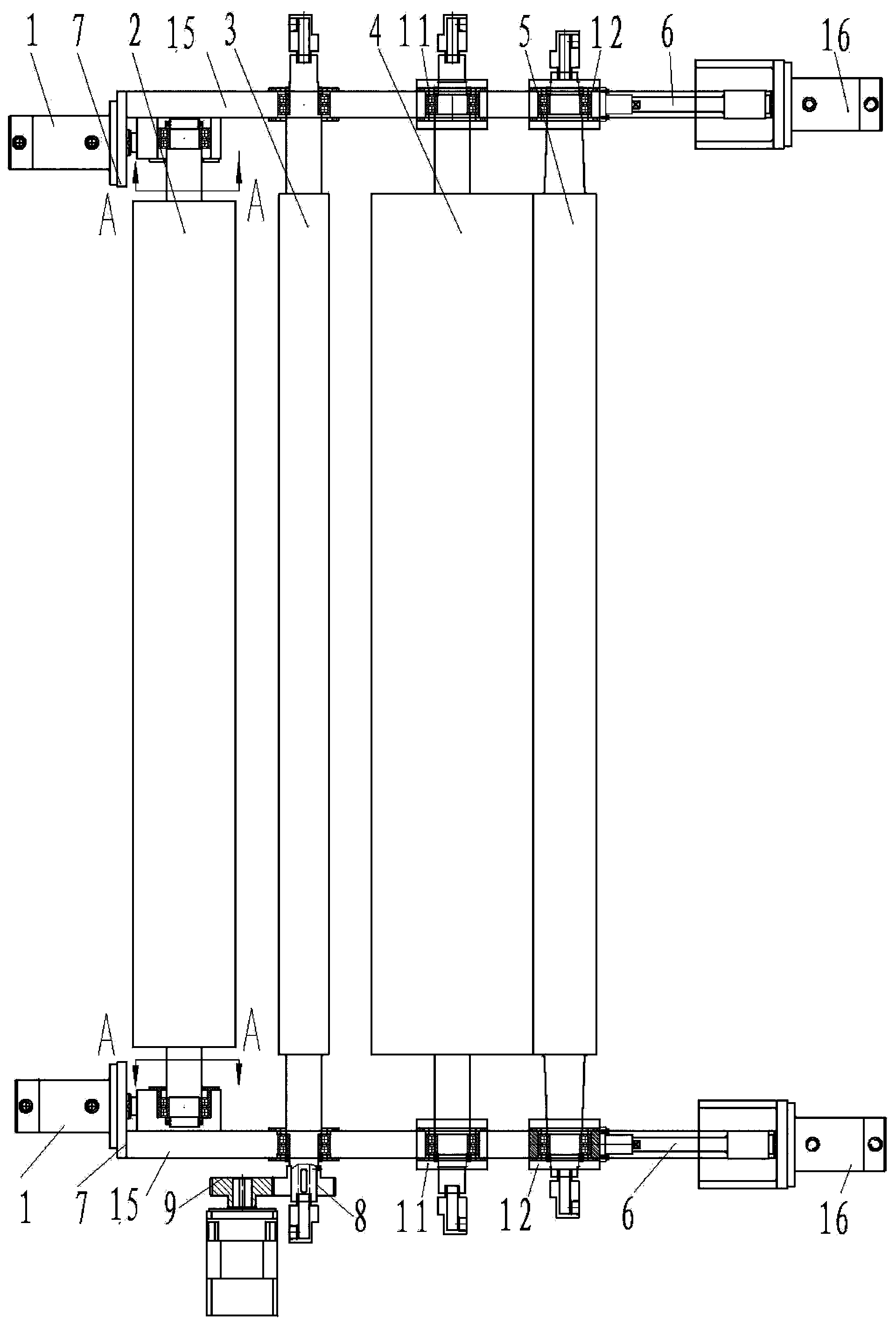

Embossing device of large-width wallpaper device

InactiveCN103407206AIncrease stiffnessImprove uniformityMechanical working/deformationPulp and paper industryPiston rod

The invention discloses an embossing device of a large-width wallpaper device. An opposite-pressing rubber covered roller, an embossing roller, an embossing rubber covered roller and a back-pressing steel roller are sequentially installed between wallboards on the two sides. The two ends of the opposite-pressing rubber covered roller are respectively and fixedly connected with a sliding block. Each sliding block is arranged on a guiding rail inside an opposite-pressing rubber covered roller support. The two opposite-pressing rubber covered roller supports are fixed on the wallboards on the two sides respectively. A left embossing oil cylinder is further fixed on each opposite-pressing rubber covered roller support. A piston rod of each left embossing oil cylinder is connected with the sliding block on the same side. The two ends of the embossing rubber covered roller are arranged on the wallboards on the two sides in a sliding mode respectively through an embossing rubber covered roller sliding base. The two ends of the back-pressing steel roller are arranged on the wallboards on the two sides in a sliding mode respectively through a pressed steel roller sliding base. Each pressed steel roller sliding base is connected with a piston rod of a right embossing oil cylinder through a connecting rod. The two right embossing oil cylinders are fixed on the wallboards on the two sides respectively through a set of oil cylinder supports. The embossing device of the large-width wallpaper device is simple in structure and meets the production requirements of large-width wallpaper.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

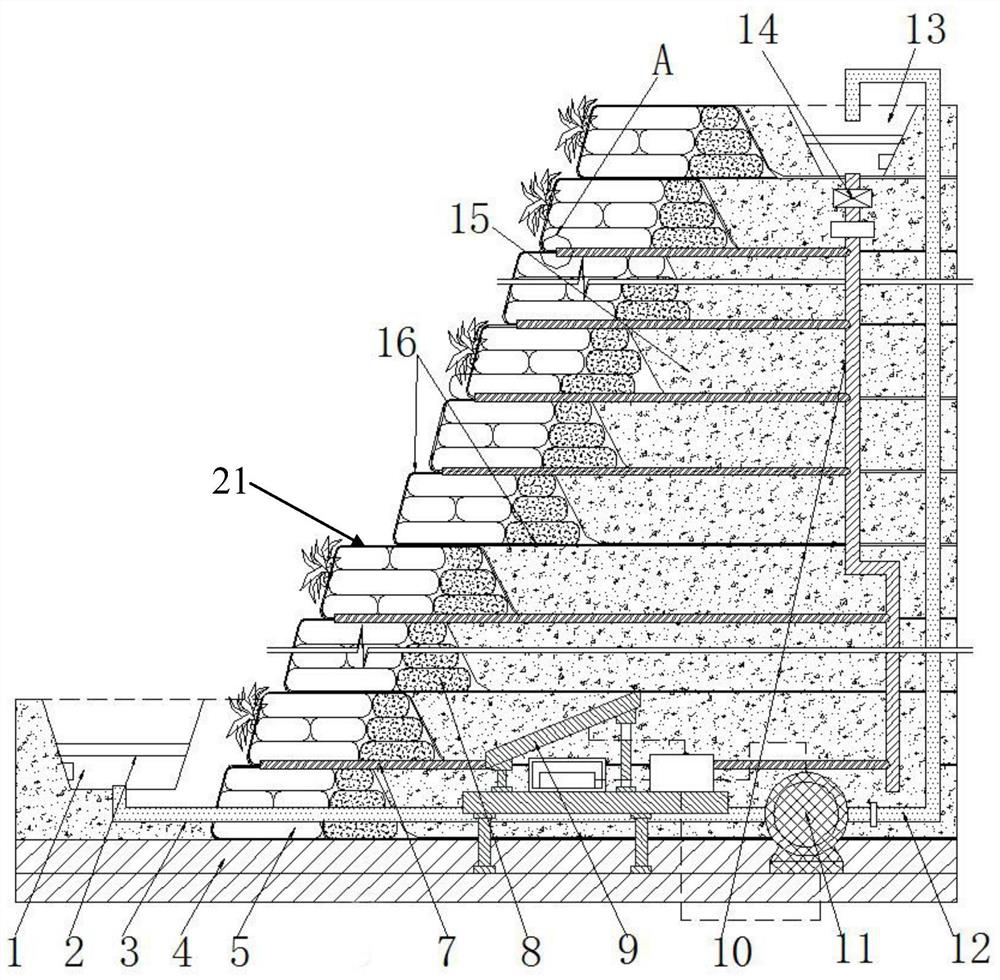

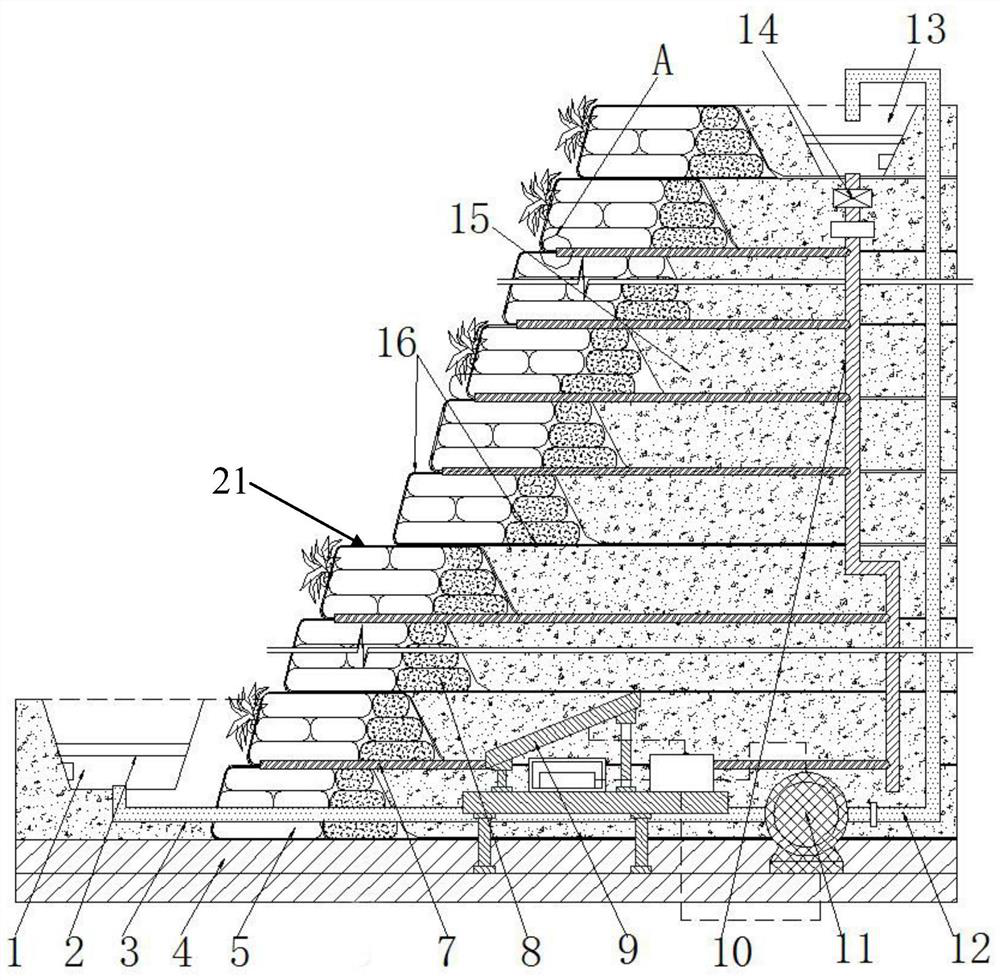

Solar drip irrigation system for ecological reinforced soil slope structure and laying method of solar drip irrigation system

ActiveCN111642369APromote penetrationPromote infiltration irrigationFatty/oily/floating substances removal devicesSewerage structuresWater deliveryDitch

The invention discloses a solar drip irrigation system for an ecological reinforced soil slope structure. The structure comprises a drainage ditch, an intercepting ditch and soil planting bags, wherein a water delivery pipe is mounted in the drainage ditch and fixedly connected with the inlet end of a water pump, a water replenishing pipe is fixedly connected with the outlet end of the water pump,and the upper end of the water replenishing pipe extends into the intercepting ditch; the intercepting ditch is formed in the top of the slope surface, a main pipeline is installed in the intercepting ditch, meanwhile, an electromagnetic valve and a filter are installed on the main pipeline, a roadbed is arranged on the lower side of each gravel layer, and a solar panel is fixed to the slope toethrough a support. According to the solar drip irrigation system for the ecological reinforced soil slope structure, rainwater collected in the drainage ditch can be supplemented to the intercepting ditch under the action of the water pump, the rainwater is recycled, and time and labor are saved.

Owner:CHINA ACAD OF TRANSPORTATION SCI

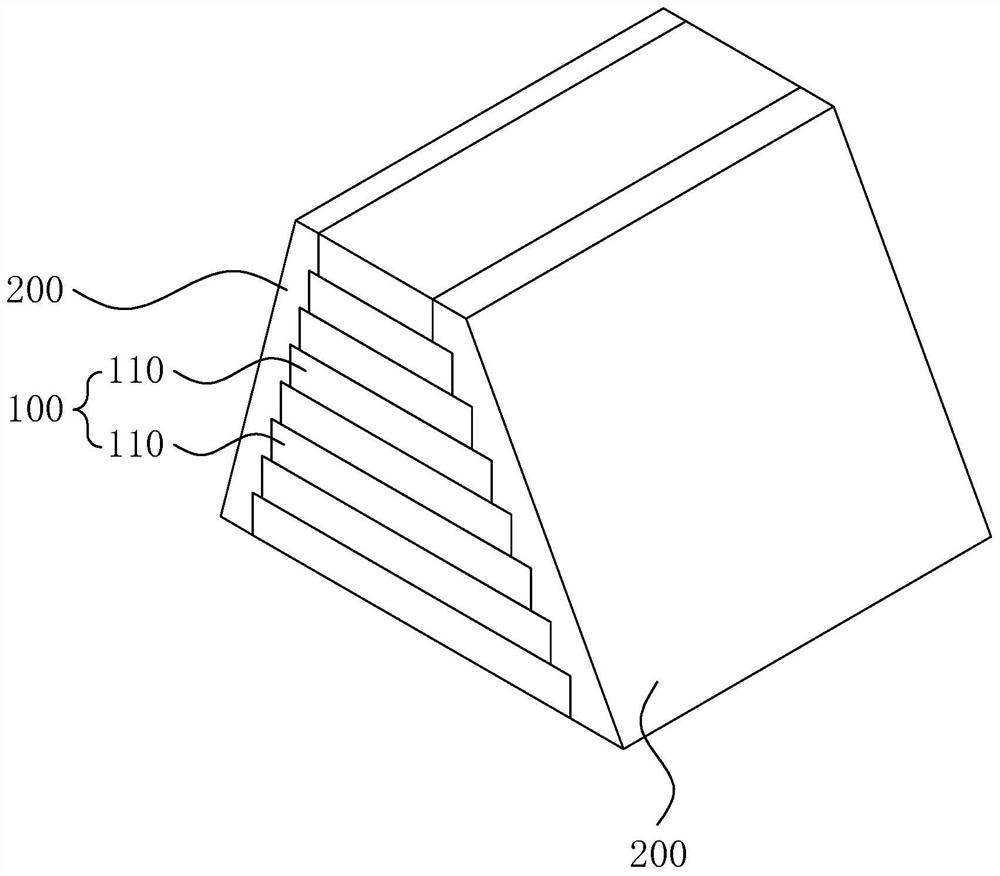

Direct-writing forming based preparation method for multielement ceramic functional gradient material

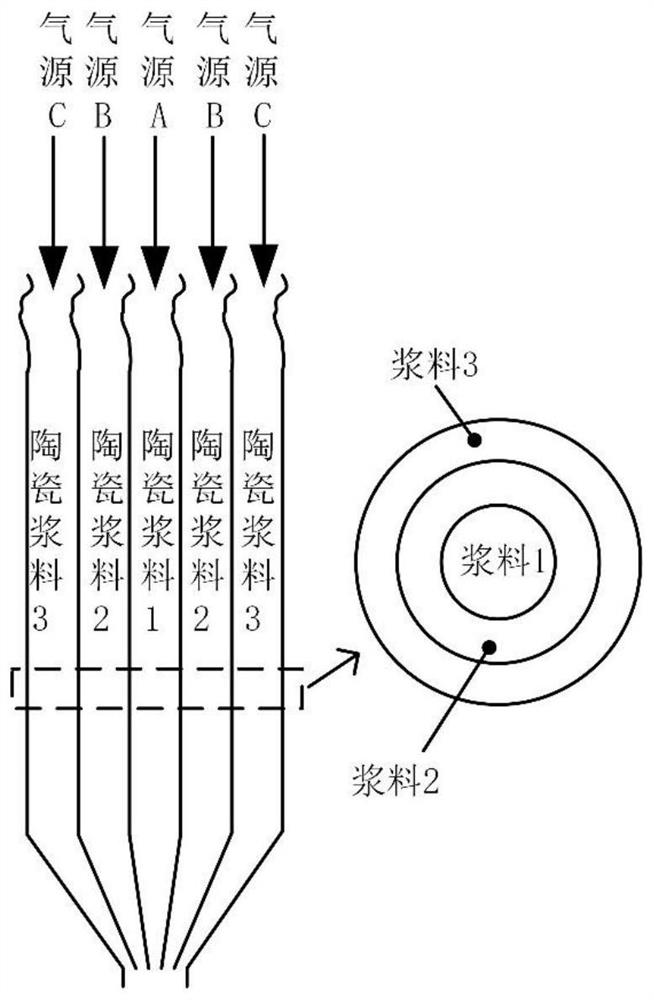

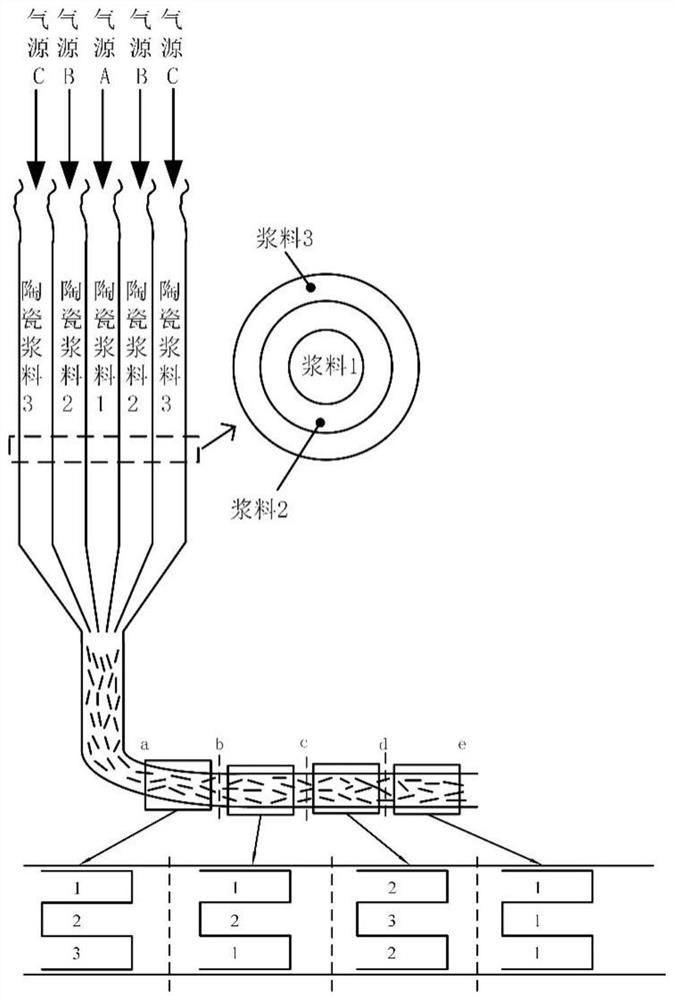

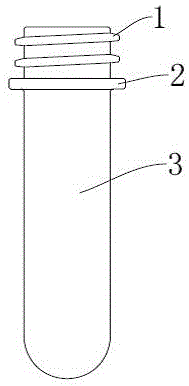

InactiveCN113001706ALow costUniform and stable dispersionAdditive manufacturing apparatusCeramic shaping apparatusFreeze-dryingFunctionally gradient material

The invention discloses a direct-writing forming based preparation method for a multielement ceramic functional gradient material, and belongs to the technical field of additive manufacturing. The technical problem to be solved in the invention is that there is no proper direct-writing forming technology for preparing the multielement ceramic functional gradient material. The preparation method comprises the following steps: separately injecting different ceramic slurry into multiple layers of coaxial feed cylinders; independently controlling each layer of the feed cylinders to perform extrusion in a direct-writing forming process, thereby obtaining multielement ceramic functional gradient material blanks; and freeze-drying, and vacuum-sintering to obtain the multielement ceramic functional gradient material. A compounding way of multielement materials can be adjusted, so that control on functional gradient of the ceramic materials is realized, and a design range of the ceramic functional gradient material is increased.

Owner:刘宇涵

Blow-molding blank cooling mounting base

Owner:CHONGQING YONGGANG RUBBER & PLASTIC

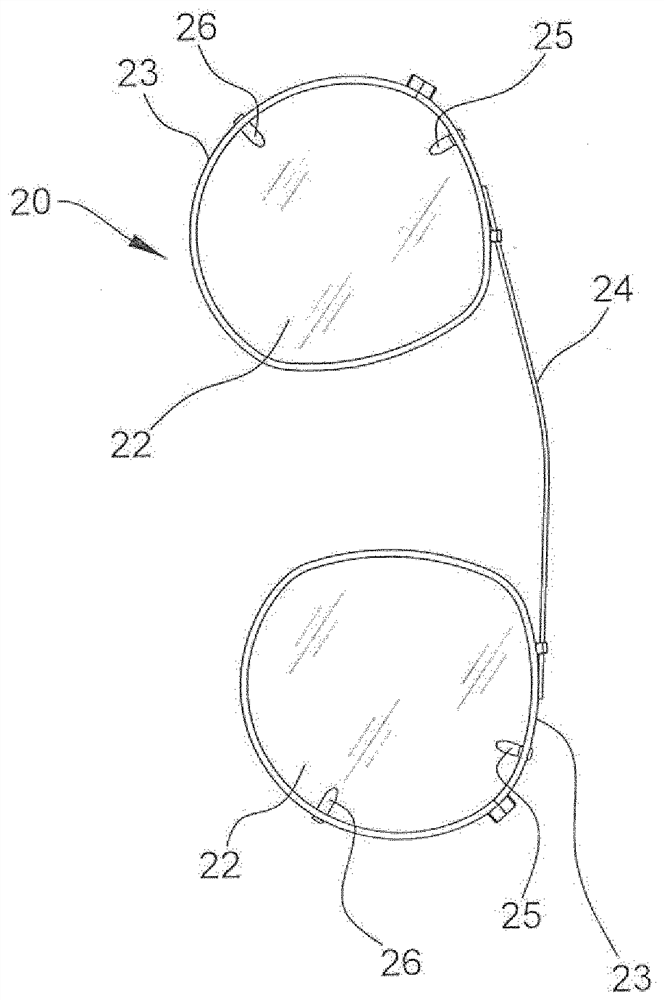

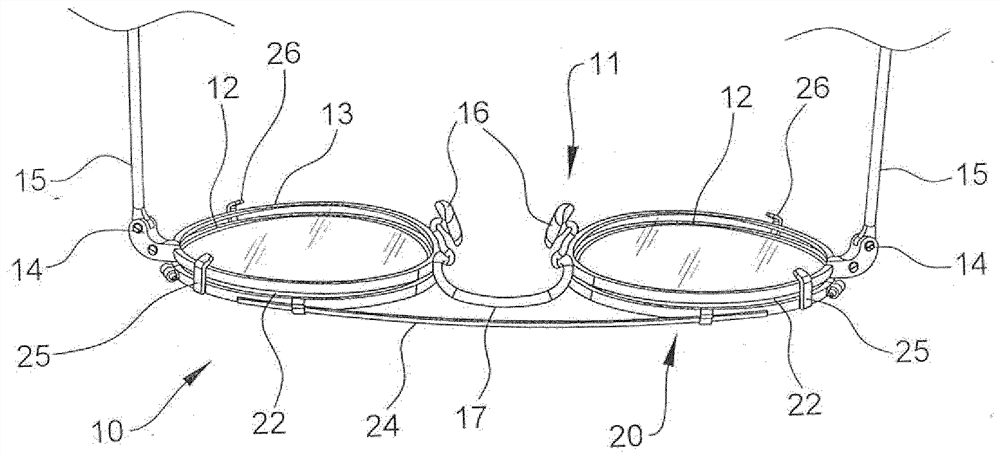

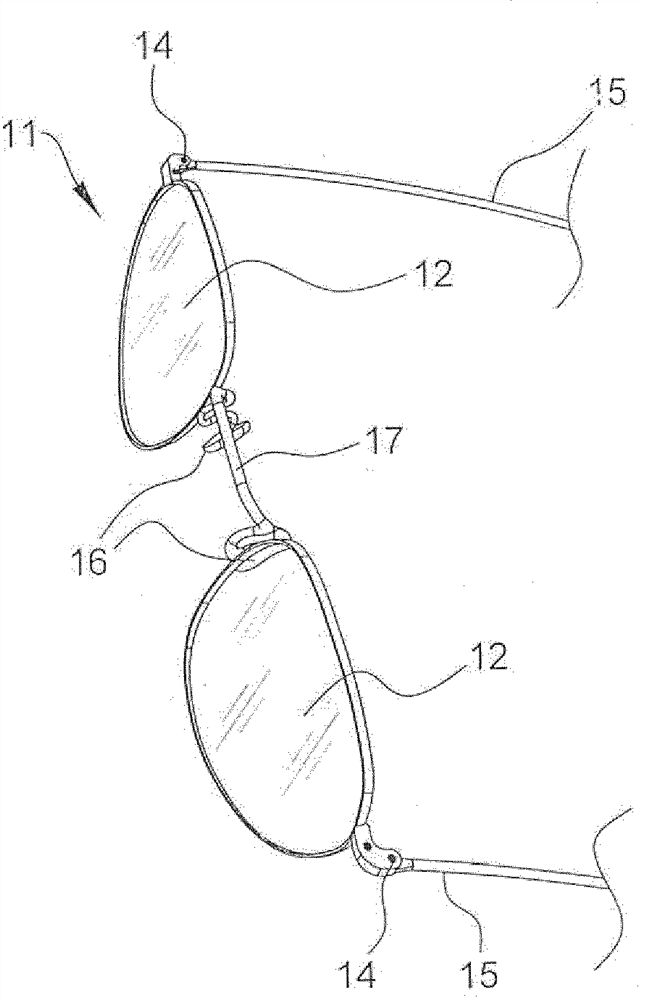

Spectacles and use of spectacles having a spectacle frame and an additional frame

PendingCN112041731ALow costReduce variantAuxillary optical partsOptical partsEyewearVisual perception

The invention relates to spectacles having a spectacle frame (11) and at least one additional frame (20) that can be placed on the front of said spectacle frame so as to be removable, both frames having lenses (12, 22) made of transparent material. The lenses (12) of the spectacle frame (11) are varifocal lenses for the purpose of correcting vision for different distance ranges in order to achievein each case maximum or clear visual acuity for at least one distance range, while the lenses (22) of the additional frame (20) are single-vision lenses or varifocal lenses. In combination with the lenses (12) of the spectacle frame (11), the lenses of the additional frame correct vision in a manner customized to the needs of the user. In a simple, cost-effective and convenient manner, a broad field of sharp vision in all distance ranges is afforded to the user, and therefore significantly improved vision comfort tailored to their requirements is provided.

Owner:安德里斯拜德

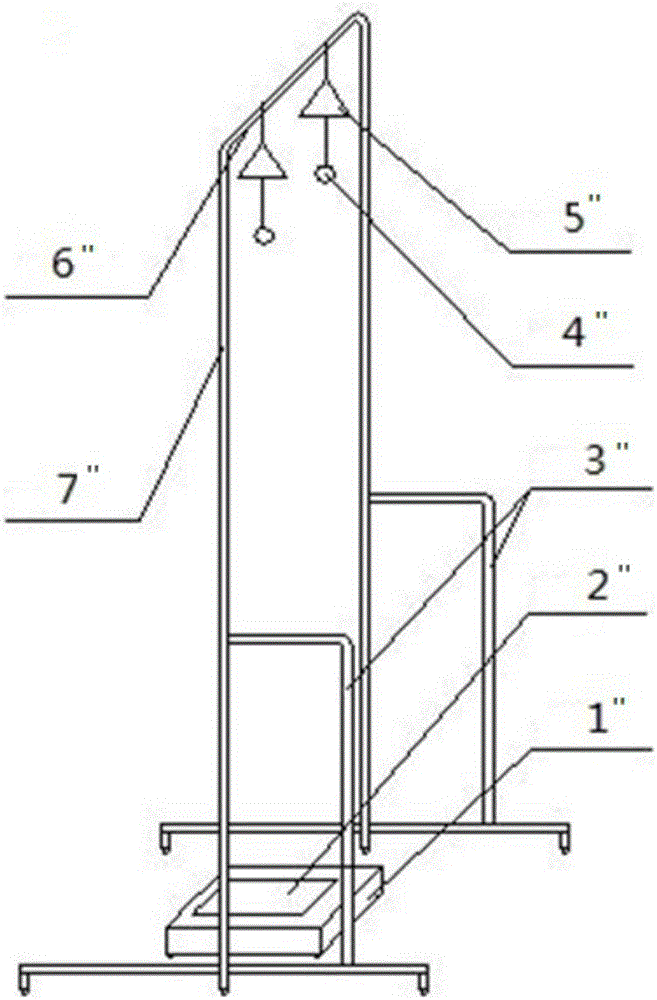

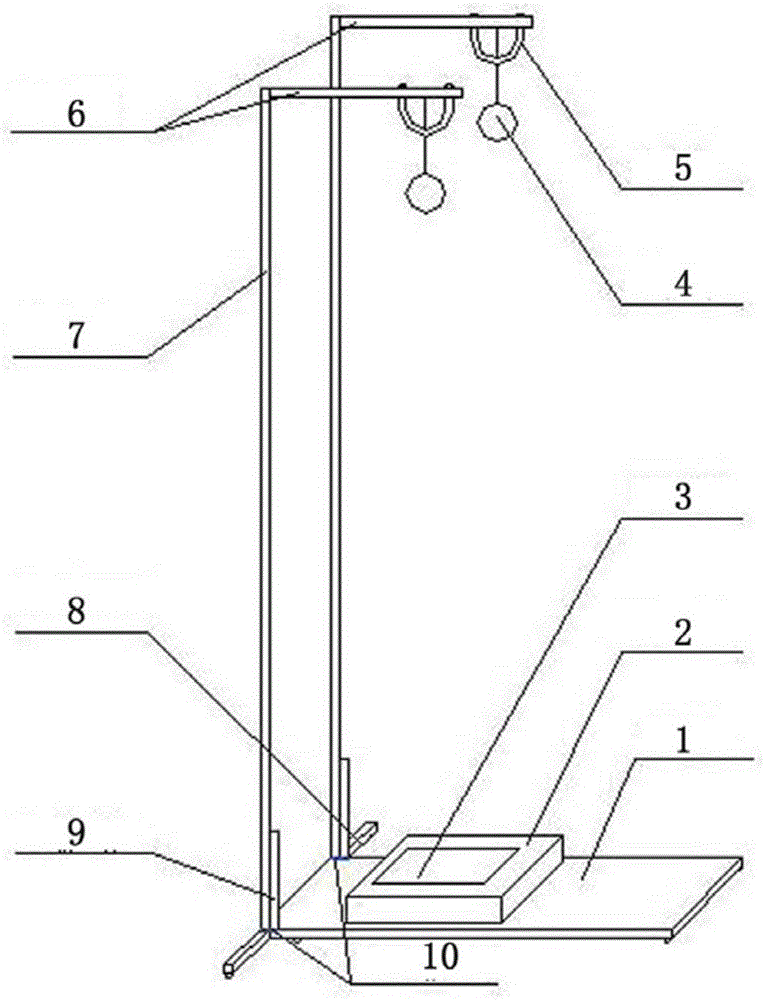

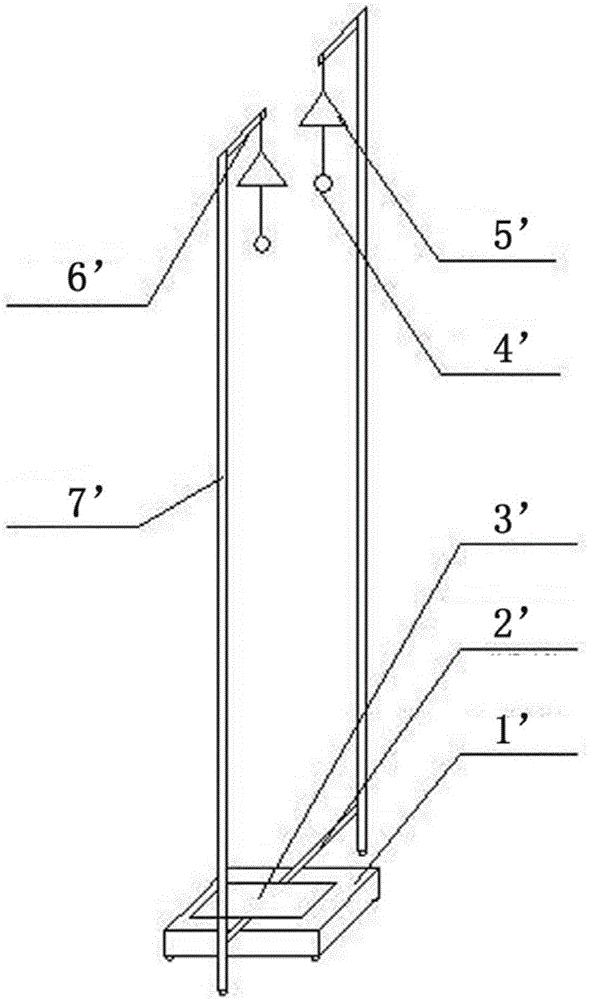

Novel qi and blood promoting machine

ActiveCN105078729ANo risk of fallingIncrease swingElectrotherapyVibration massageEngineeringBlood circulating

The invention relates to a novel qi and blood promoting machine.The qi and blood promoting machine has three structures. A first structure comprises a bottom plate (1), a qi and blood circulating machine (2), a footboard (3), a pull handle (5), an upper pull rod (6), a vertical rod (7), a bottom-widening rear rod (8) and an auxiliary rod (9). A second structure comprises a qi and blood circulating machine (1'), a triangular transverse rod (2'), a footboard (3'), a safety buckle (4'), a pull handle (5'), an upper pull rod (6') and a vertical rod (7'). A third structure comprises a qi and blood circulating machine (1''), a footboard (2''), a grab bar (3''), a safety buckle (4''), a pull handle (5''), an upper transverse rod (6'') and a vertical rod (7''). The technical scheme provided by the novel qi and blood promoting machine is advantaged by being convenient in installation, safe in operation and low in noise and is detachable, firm and not easily damaged and helps to improve usage effect.

Owner:HENAN PUKANG HEALTH CARE TECH CO LTD

Embossing device of large-width wallpaper device

InactiveCN103407206BIncrease stiffnessImprove uniformityMechanical working/deformationPulp and paper industryPiston rod

The invention discloses an embossing device of a large-width wallpaper device. An opposite-pressing rubber covered roller, an embossing roller, an embossing rubber covered roller and a back-pressing steel roller are sequentially installed between wallboards on the two sides. The two ends of the opposite-pressing rubber covered roller are respectively and fixedly connected with a sliding block. Each sliding block is arranged on a guiding rail inside an opposite-pressing rubber covered roller support. The two opposite-pressing rubber covered roller supports are fixed on the wallboards on the two sides respectively. A left embossing oil cylinder is further fixed on each opposite-pressing rubber covered roller support. A piston rod of each left embossing oil cylinder is connected with the sliding block on the same side. The two ends of the embossing rubber covered roller are arranged on the wallboards on the two sides in a sliding mode respectively through an embossing rubber covered roller sliding base. The two ends of the back-pressing steel roller are arranged on the wallboards on the two sides in a sliding mode respectively through a pressed steel roller sliding base. Each pressed steel roller sliding base is connected with a piston rod of a right embossing oil cylinder through a connecting rod. The two right embossing oil cylinders are fixed on the wallboards on the two sides respectively through a set of oil cylinder supports. The embossing device of the large-width wallpaper device is simple in structure and meets the production requirements of large-width wallpaper.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

Fishbone type ion permeable membrane drum

The invention relates to a fishbone type ion permeable membrane drum. The drum comprises an inner container and an outer barrel, wherein fishbone type inclined lines are formed on an outer barrel wall and form an angle of 60 degrees with the axial direction of the outer barrel; rib groups are arranged on the fishbone type inclined lines and comprise small ribs, and a large rib is arranged on the rib groups; and the rib groups are parallel to the round cross section of the outer barrel. The drum is simple in structure, is low in cost and can produce an ion permeable membrane which can be used for solving the short circuit problem caused by active material falling during a storage battery use process.

Owner:JIANGSU EPCOH TECH

Center regulating rotary table for Helmholtz coil

ActiveCN103048551BReasonable designEasy to assemble and disassembleElectromagentic field characteristicsHelmholtz coilEngineering

The invention relates to a center regulating rotary table for a Helmholtz coil. The device comprises a main structural frame (29) and an azimuth and lifting frame (37), wherein the main structural frame (29) comprises two circular ring-shaped plates (2) which are coaxially fixed; the circular ring-shaped plates (2) are provided with semicircular holes (49); the peripheral ring-shaped surfaces of the circular ring-shaped plates (2) are provided with grooves around the whole peripheries; the coil is wound in the grooves; the azimuth and lifting frame comprises a height regulating unit, a horizontal azimuth regulating unit and an inclination angle regulating unit; and by the arrangement of the units, high-accuracy three-dimensional continuous regulation on the height, the azimuth of spherical coordinates and the inclination angle position is implemented. The center regulating rotary table for the Helmholtz coil has the advantages that each part of the Helmholtz coil disclosed by the invention is reasonably designed, is simple and convenient to assemble and disassemble, is easy to frequently disassemble and carry and can easily implement omnibearing high-accuracy detection; and the Helmholtz coil disclosed by the invention has field windproof design and has good outdoor use applicability and strong anti-interference performance.

Owner:NAT SPACE SCI CENT CAS

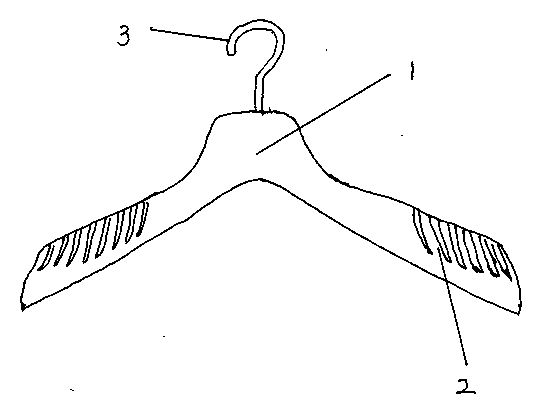

Anti-slipping clothes rack

The invention discloses an anti-slipping clothes rack which comprises a clothes rack body and a clothes rack hook. Anti-slipping protrusions are arranged at the load bearing positions of the clothes rack body and made of a soft plastic material, and the anti-slipping clothes rack effectively prevents clothes from dropping.

Owner:DALIAN SHENGJUN GARMENT ACCESSORIES

A solar drip irrigation system for ecological reinforced soil slope structure and its laying method

ActiveCN111642369BImprove permeabilityPromote infiltration irrigationFatty/oily/floating substances removal devicesSewerage structuresSolenoid valveDrip irrigation

The invention discloses a solar drip irrigation system for an ecological type reinforced soil slope structure, which comprises a drainage ditch, a water intercepting ditch and a soil planting bag, a water delivery pipe is installed in the drainage ditch, and the inlet of the water delivery pipe and the water pump At the same time, the water supply pipe is fixedly connected with the outlet end of the water pump, and the upper end of the water supply pipe extends to the inside of the intercepting ditch. The intercepting ditch is set on the top of the slope, and the main pipe is installed inside the intercepting ditch. Solenoid valves and filters are installed, the underside of the gravel layer is the roadbed, and the solar panels are fixed at the foot of the slope through brackets. The solar drip irrigation system for the ecological reinforced soil slope structure of the present invention, the rainwater collected inside the drainage ditch can be used to replenish water to the intercepting ditch under the action of the water pump, and the rainwater can be recycled, saving time and effort .

Owner:CHINA ACAD OF TRANSPORTATION SCI

Sensor device for hydraulic plunger units

ActiveCN104074736BIncreased durabilityEasy accessibilityMeasurement apparatus componentsPositive displacement pump componentsHydraulic ramEngineering

Owner:ROBERT BOSCH GMBH

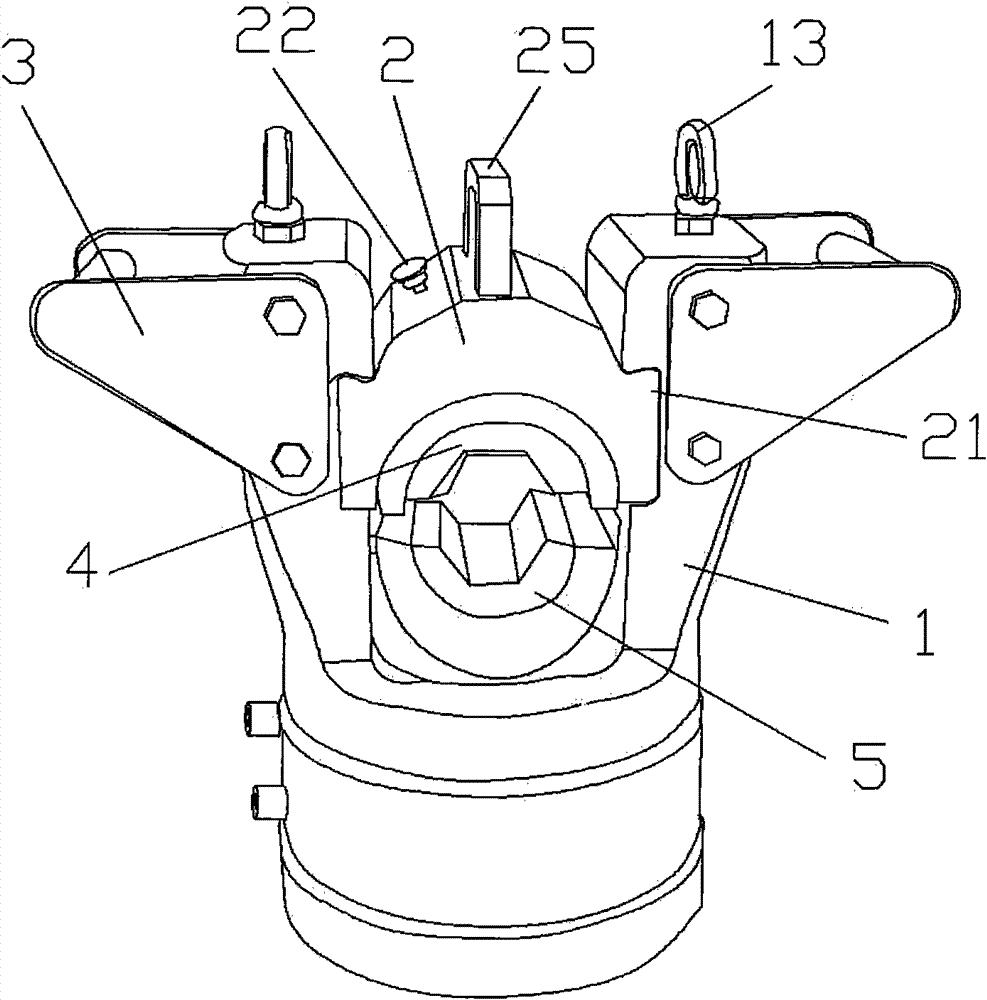

Split hydraulic clamp

InactiveCN102013615BSame stressSame plasticityLine/current collector detailsMetal-working hand toolsEngineeringMechanical engineering

Owner:吴书占

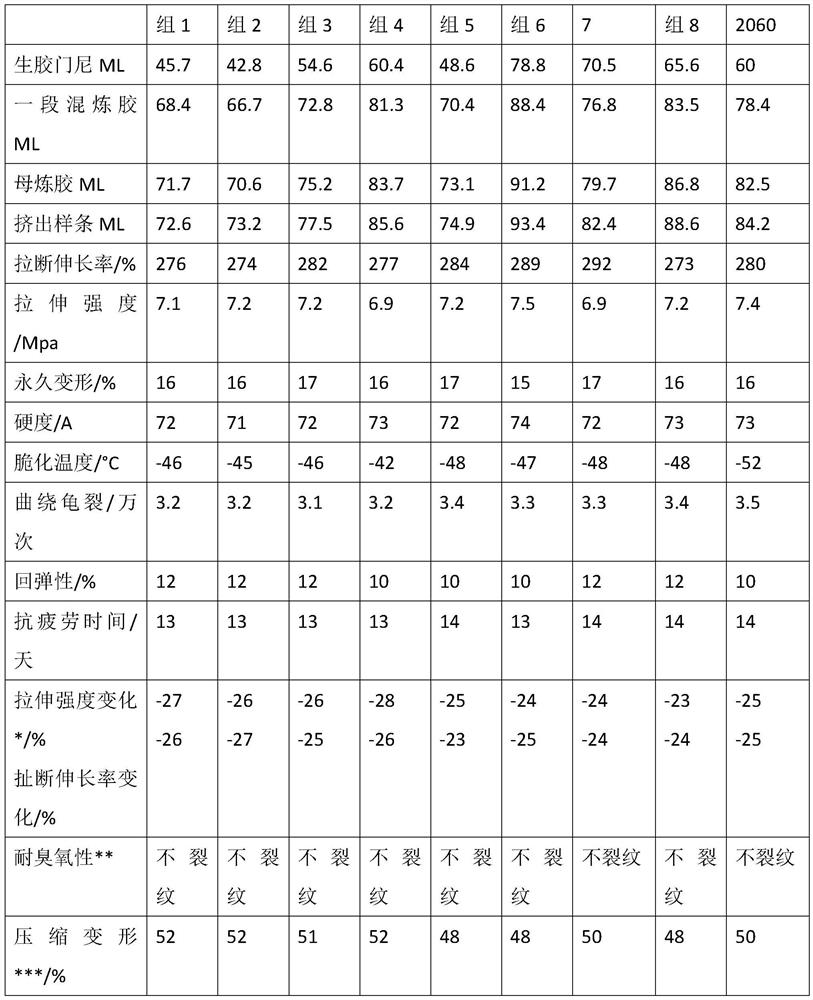

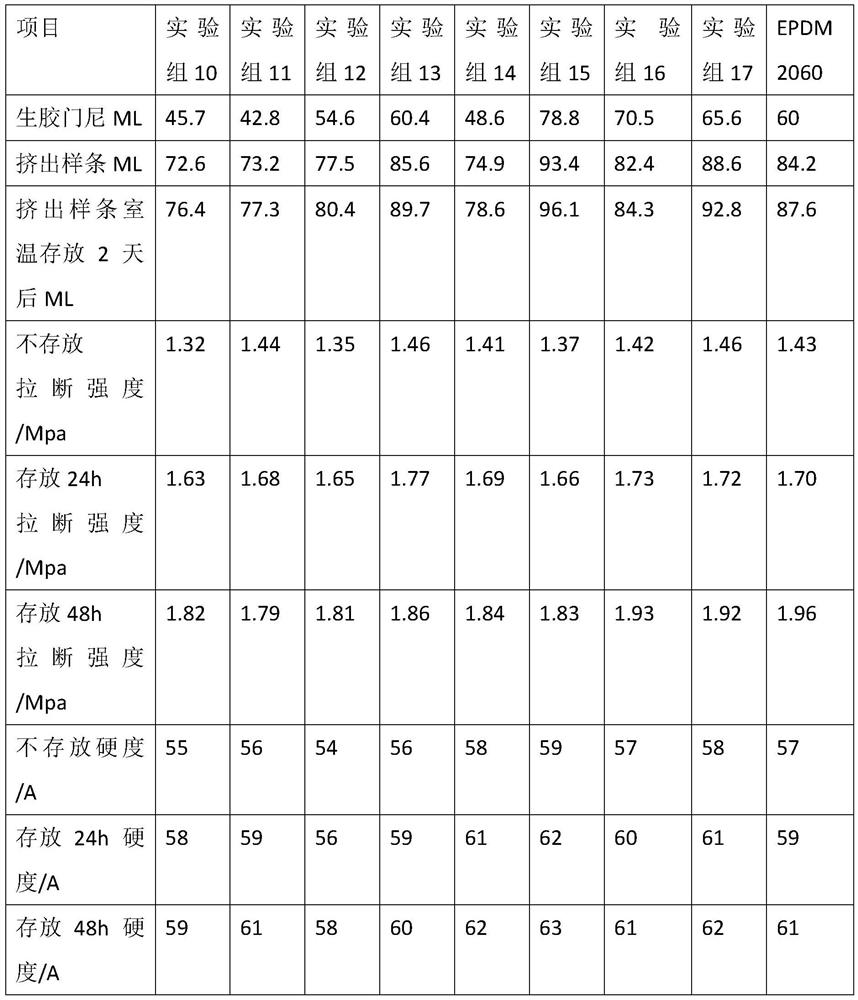

Sealing strip material based on partially hydrogenated polystyrene-b-conjugated diene/divinyl benzene random copolymer and preparation thereof

The invention discloses a sealing strip material based on a partially hydrogenated polystyrene-b-conjugated diene / divinyl benzene random copolymer and a preparation method thereof. The sealing strip material comprises a partially hydrogenated polystyrene-b-conjugated diene / divinyl benzene random copolymer, sulfur, a reinforcing agent, a filling agent, filling oil, a coupling agent, an accelerant,a post-effect vulcanizing agent and auxiliary materials such as zinc oxide, stearic acid and an anti-aging agent. The sealing strip with good physical and mechanical properties, strong ageing resistance, good heat resistance, low compression deformation, continuous tension resistance and long anti-fatigue time can be obtained through mixing, extrusion and vulcanization, and the sealing strip is particularly suitable for outdoor windows.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydraulically balanced loading type high-torque static calibration device

ActiveCN104155053BHigh precisionReduce variantForce/torque/work measurement apparatus calibration/testingFriction reductionCam

Owner:南通常测机电设备有限公司

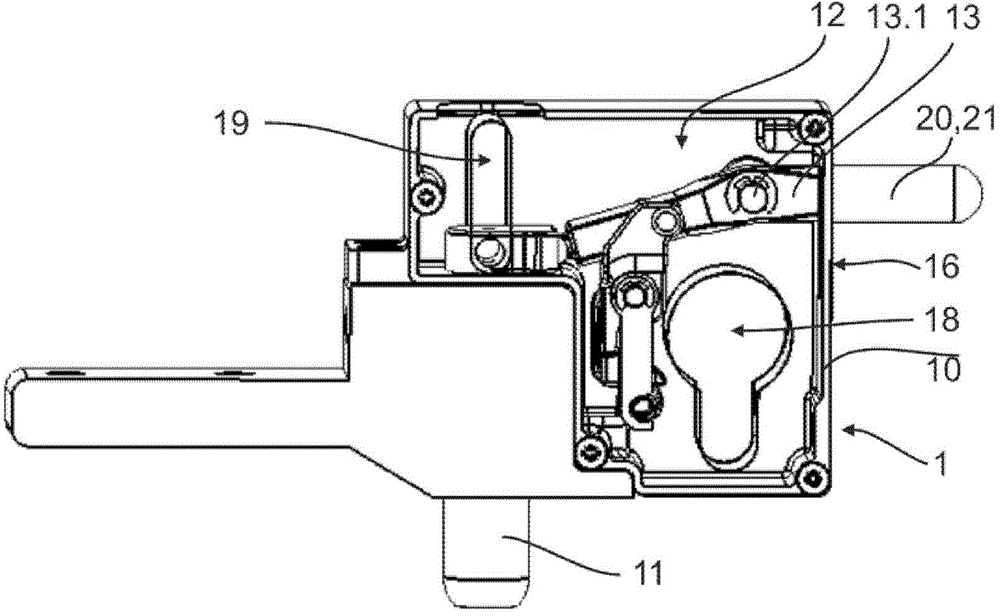

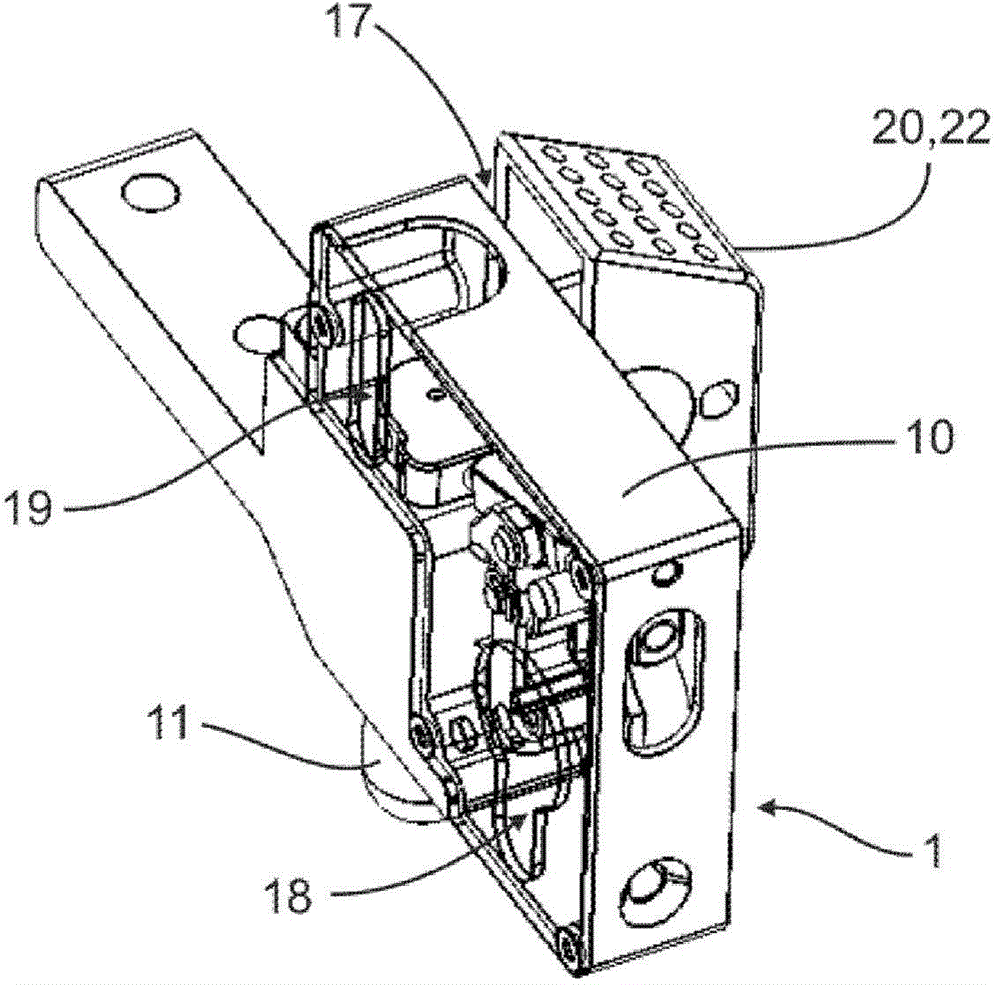

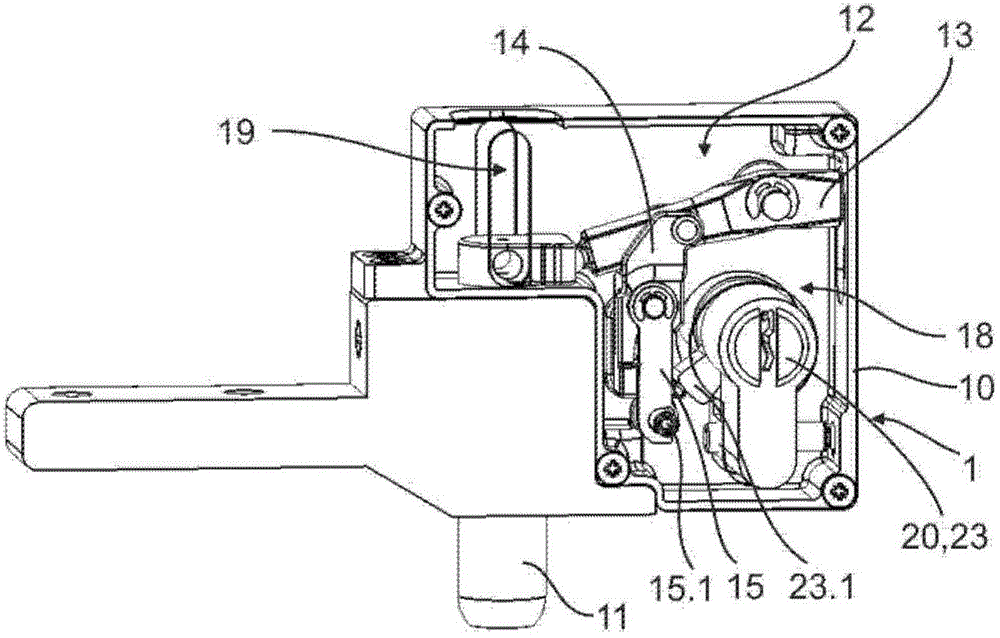

Universal lock

InactiveCN104563603AReduce variantConsistent processingConstruction fastening devicesLock casingsLocking mechanismEngineering

Owner:多玛德国有限公司

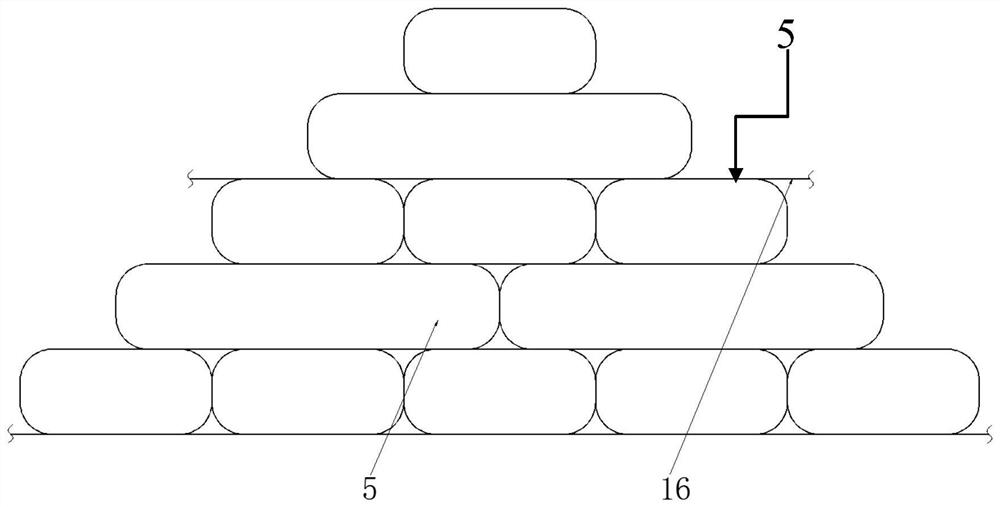

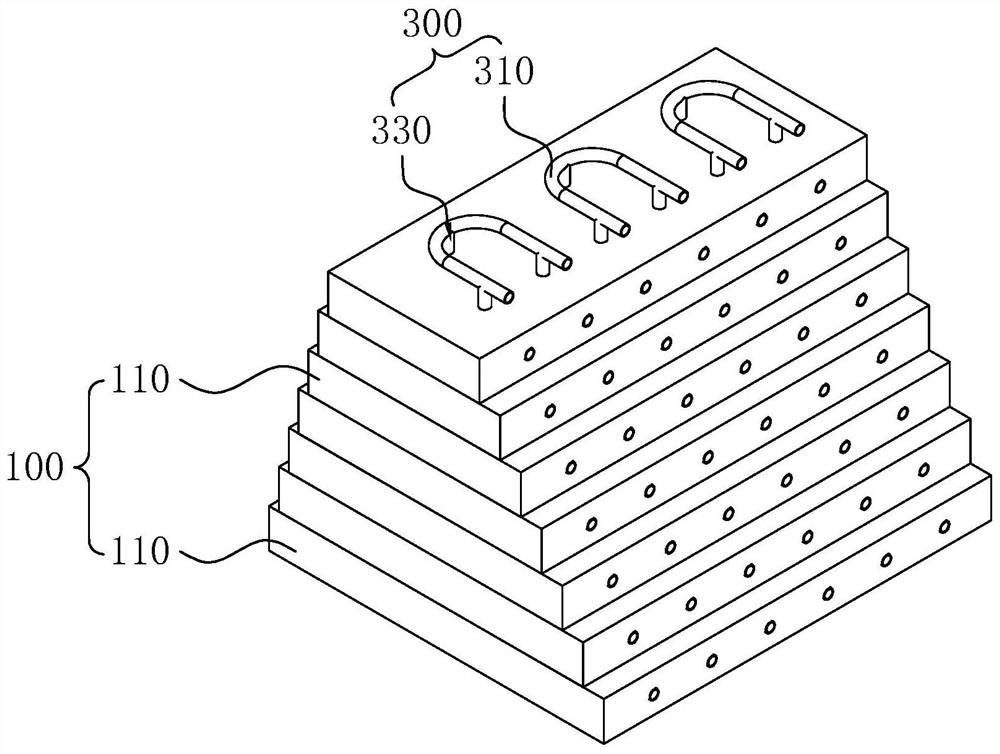

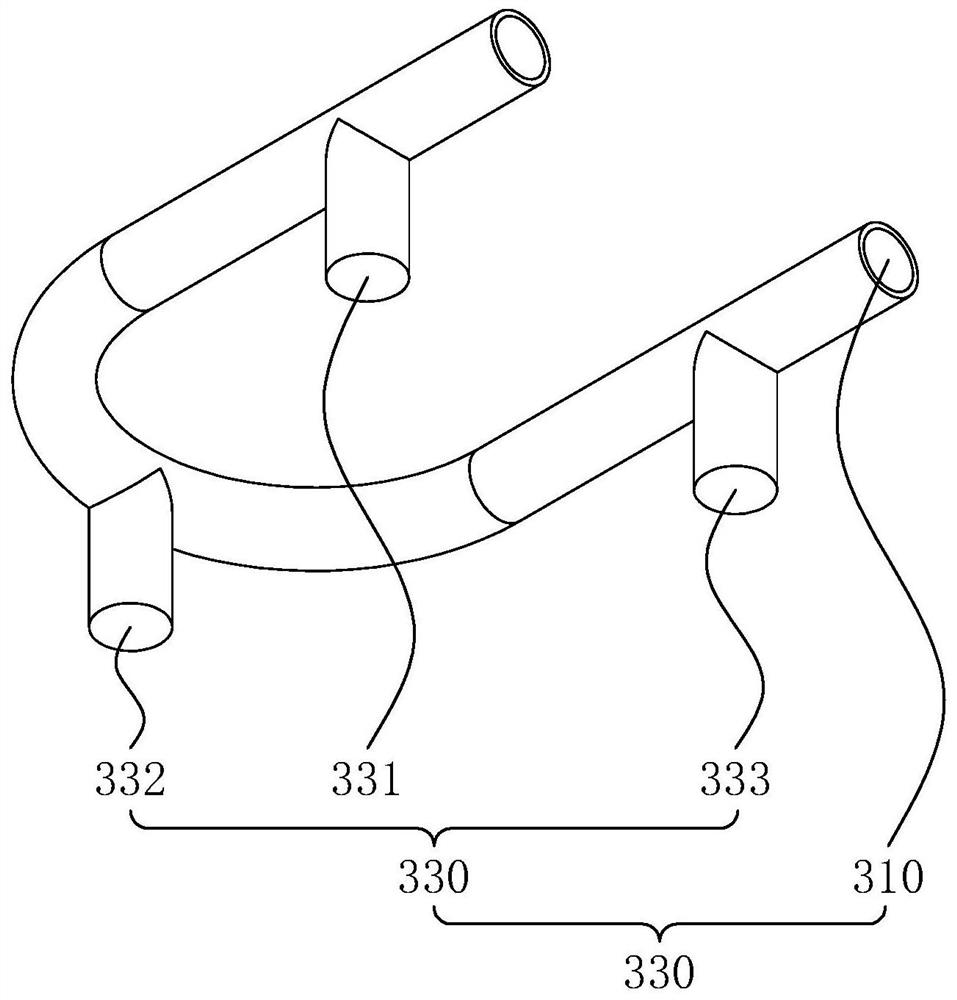

Roller compacted concrete dam structure and construction method

ActiveCN113250148AReduce warping or breakingImprove coagulation efficiencyBarrages/weirsHydro energy generationStructural engineeringRoller-compacted concrete

The invention relates to a roller compacted concrete dam structure and a construction method, and relates to the technical field of hydraulic engineering. The roller compacted concrete dam structure comprises a roller compacted concrete part and normal state concrete parts laid on the two sides of the roller compacted concrete part; the roller compacted concrete part comprises a plurality of roller compacted concrete layers; each roller compacted concrete layer is provided with a cooling mechanism; and each cooling mechanism comprises a plurality of sections of cooling pipes evenly distributed in the length direction of the corresponding roller compacted concrete layer, and every two adjacent sections of cooling pipes are not connected or flexibly connected. The construction method comprises the steps of cooling pipe laying, discharging, flattening, rolling compaction, water passing, normal state concrete pouring and the like. According to the roller compacted concrete dam structure and the construction method, the probability that the roller compacted concrete layers are damaged can be reduced, the probability that roller compacted concrete is eroded by cooling water is reduced, the solidification efficiency of the roller compacted concrete layers is improved, and accordingly the strength of a roller compacted concrete dam is improved.

Owner:山东水总有限公司

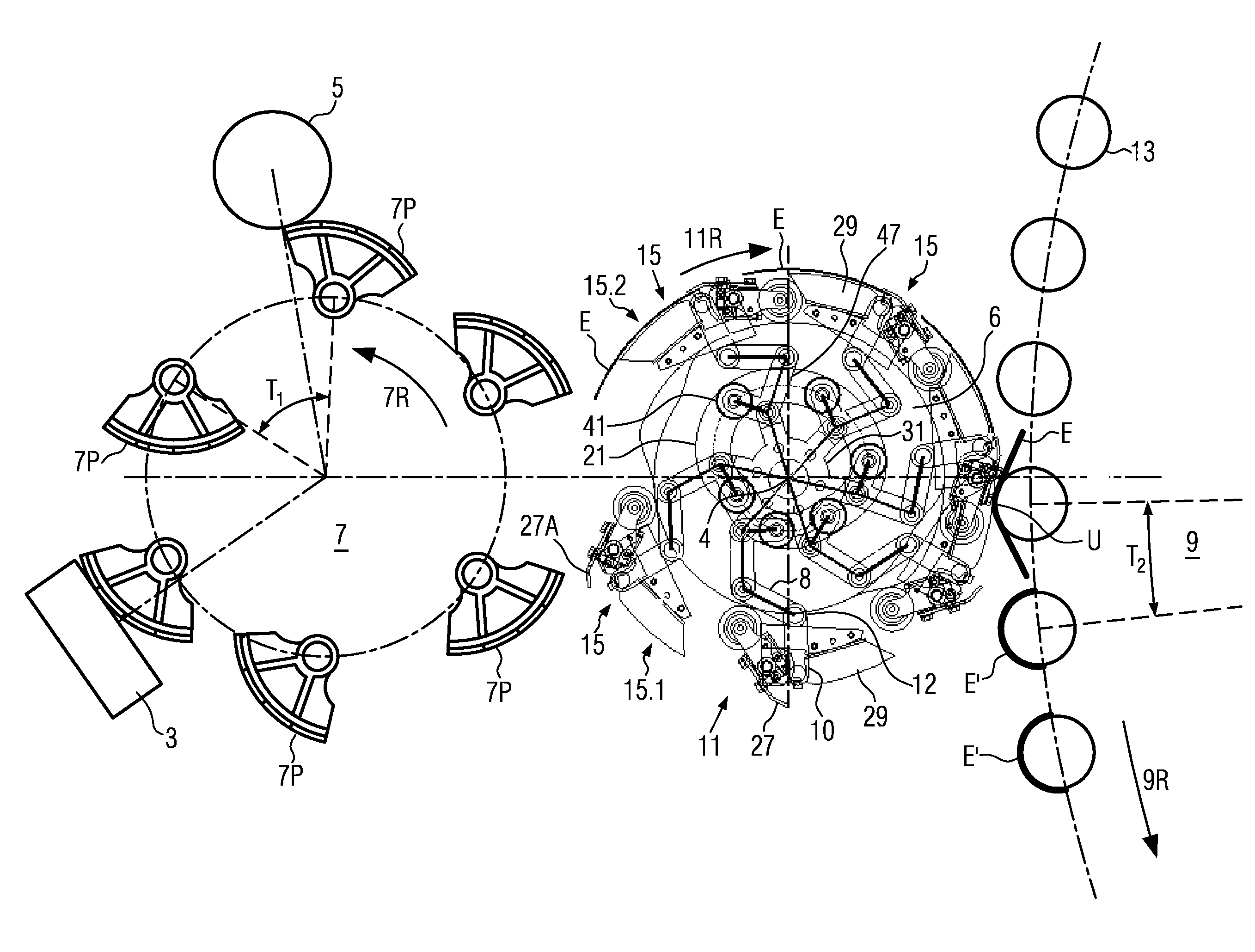

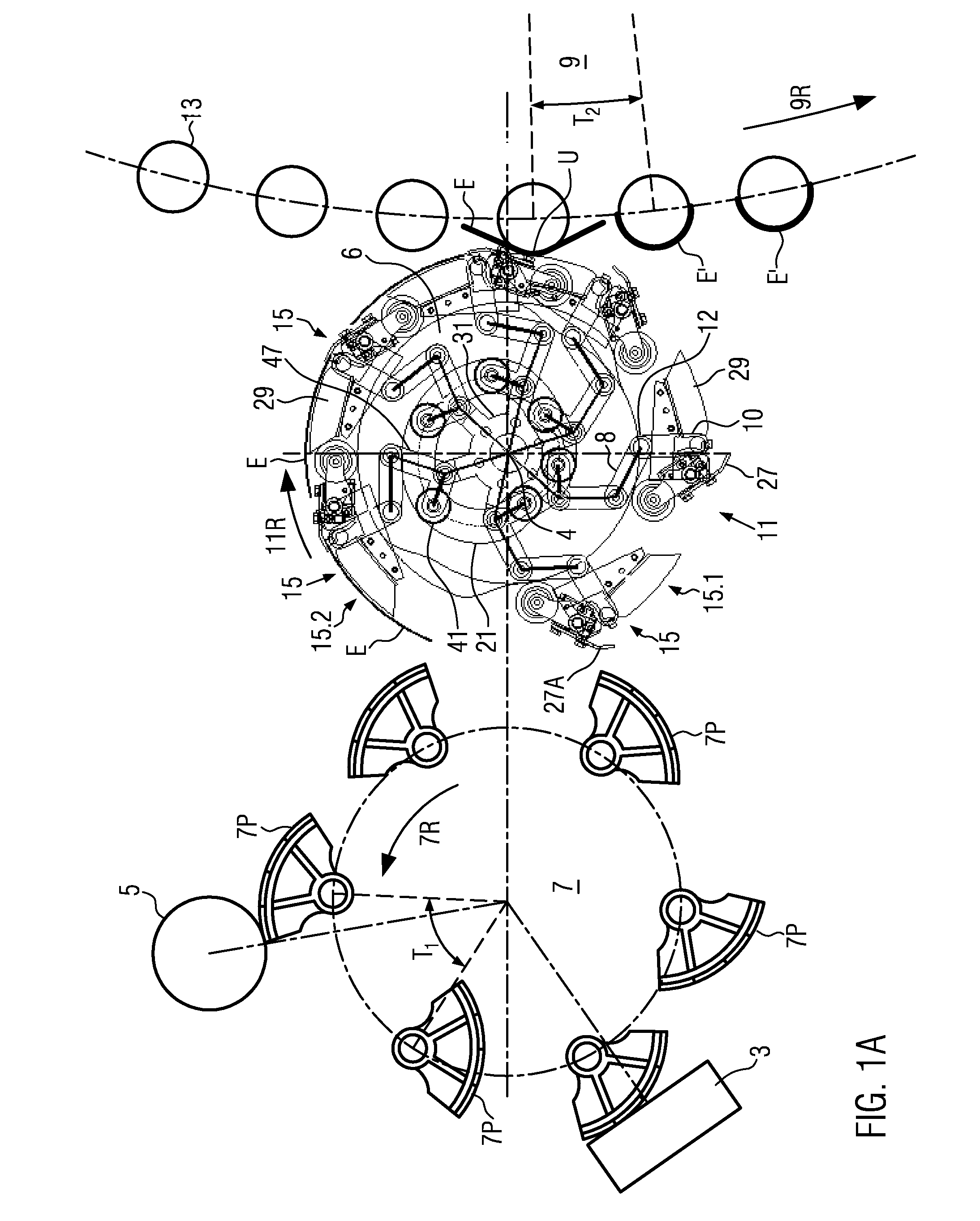

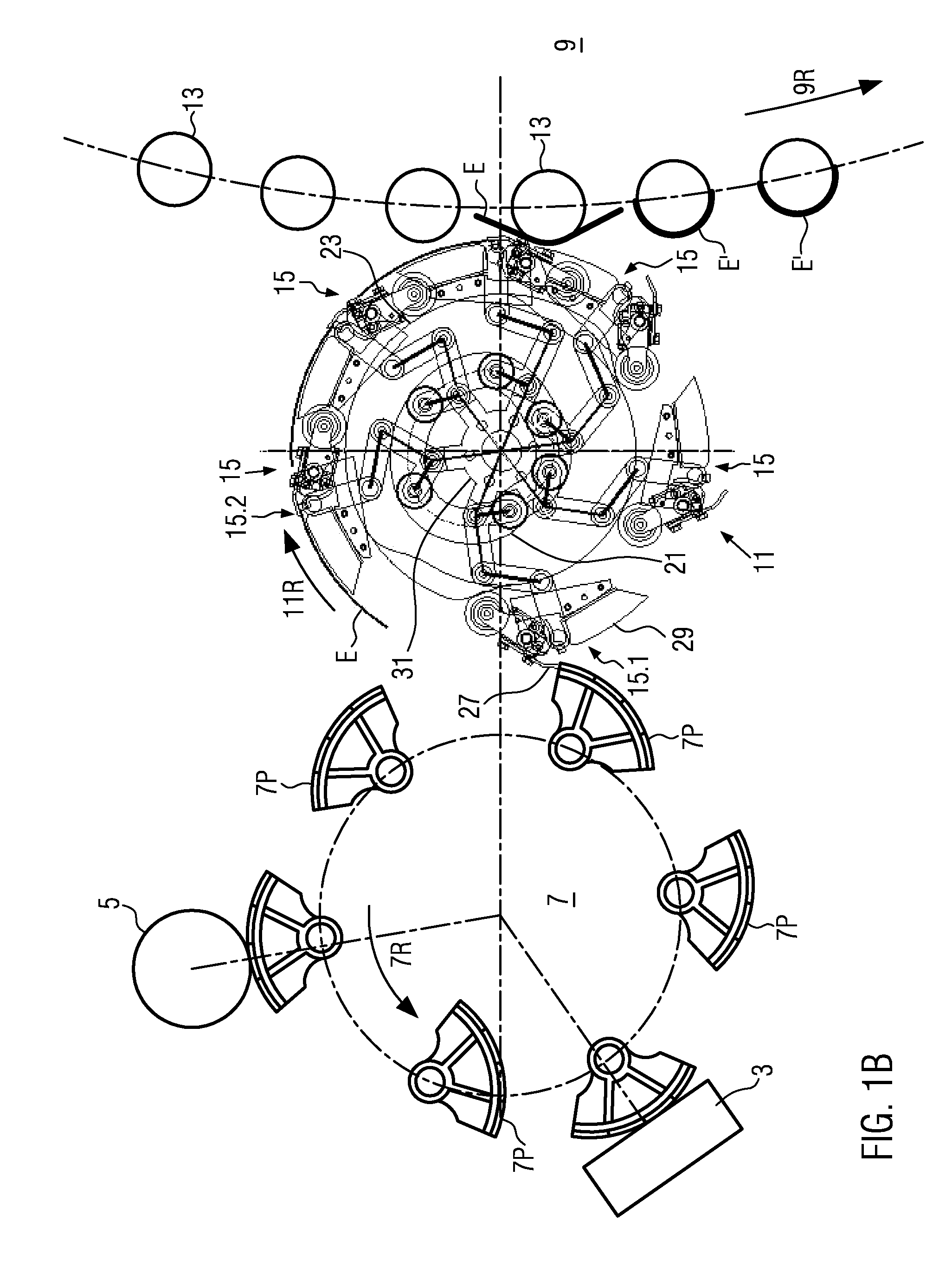

Reduction gripper for a cold glue unit

ActiveUS8790474B2Reduce variantSuitable for processingMechanical working/deformationLamination ancillary operationsMechanical engineeringRelative velocity

A device for transferring labels in a labeling machine with at least two retaining elements for holding labels, with the retaining elements being mounted offset in the circumferential direction around a gripper cylinder axle, and a mechanical control means configured to change the relative speed between the retaining elements in the circumferential direction of the gripper cylinder.

Owner:KRONES AG

Fishbone type ion permeable membrane drum

InactiveCN103035868BImprove mechanical propertiesImprove wear resistanceCell component detailsEngineeringLarge ribs

The invention relates to a fishbone type ion permeable membrane drum. The drum comprises an inner container and an outer barrel, wherein fishbone type inclined lines are formed on an outer barrel wall and form an angle of 60 degrees with the axial direction of the outer barrel; rib groups are arranged on the fishbone type inclined lines and comprise small ribs, and a large rib is arranged on the rib groups; and the rib groups are parallel to the round cross section of the outer barrel. The drum is simple in structure, is low in cost and can produce an ion permeable membrane which can be used for solving the short circuit problem caused by active material falling during a storage battery use process.

Owner:JIANGSU EPCOH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com