Blow-molding blank cooling mounting base

A technology of mounting seat and blank body, which is applied in the field of blow molding blank cooling mounting seat, can solve problems such as product failure, and achieve the effect of reducing deformation and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

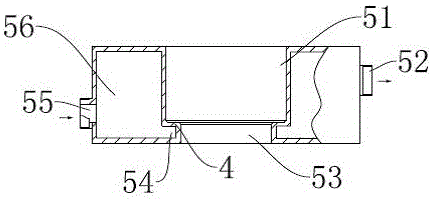

[0019] Such as image 3 Shown is a schematic structural view of the cooling mounting seat of the blow molding embryo body seat of the present invention. The cooling mounting seat of the blow molding embryo body seat is in the form of a cylinder as a whole, and a housing cavity 51 of a cylindrical space is opened on the central axis of the cylinder. The bottom is provided with a through hole 53, and a circulation flow channel is provided between the outer wall of the cooling mounting seat of the blow molding embryo body seat, the accommodation cavity 51 and the through hole 53. Set on the circumference of the through hole 53, the flow channel cavity 56 is also set on the circumference of the receiving cavity 51, the ring cavity 54 communicates with the flow channel cavity 56, and there is an outwardly protruding inflow under the left side wall of the flow channel cavity 56. The mouth 55 is provided with an outwardly protruding outlet 52 above the right side wall of the runner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com