Direct-writing forming based preparation method for multielement ceramic functional gradient material

A functionally graded material, direct writing technology, applied in the field of additive manufacturing, can solve the problems of difficult preparation of controllable multi-material ink, less research on multi-material direct writing, etc., to expand the design range, low cost, high precision The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

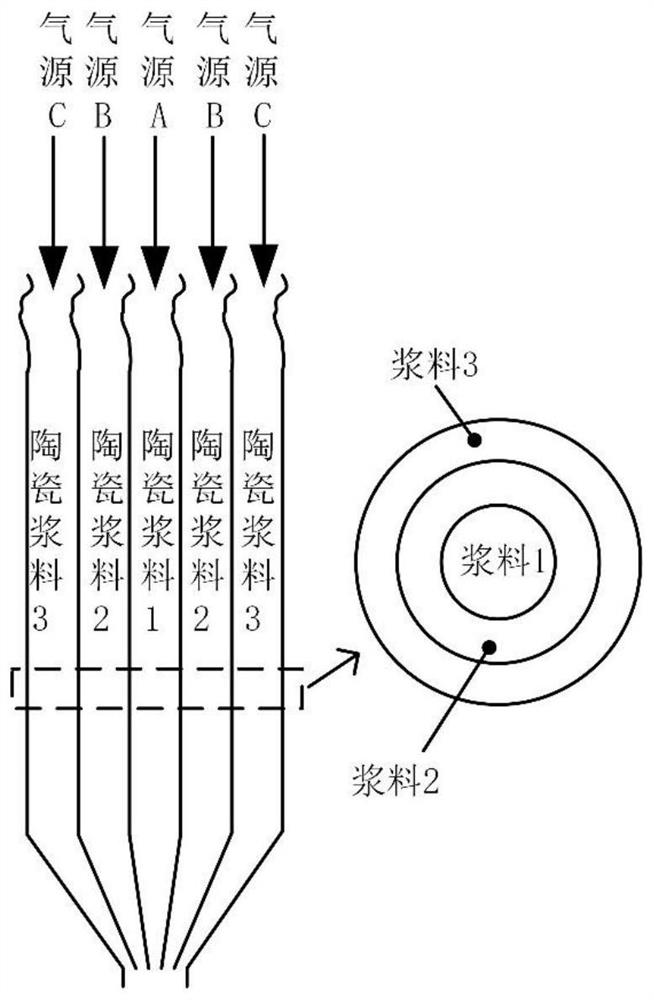

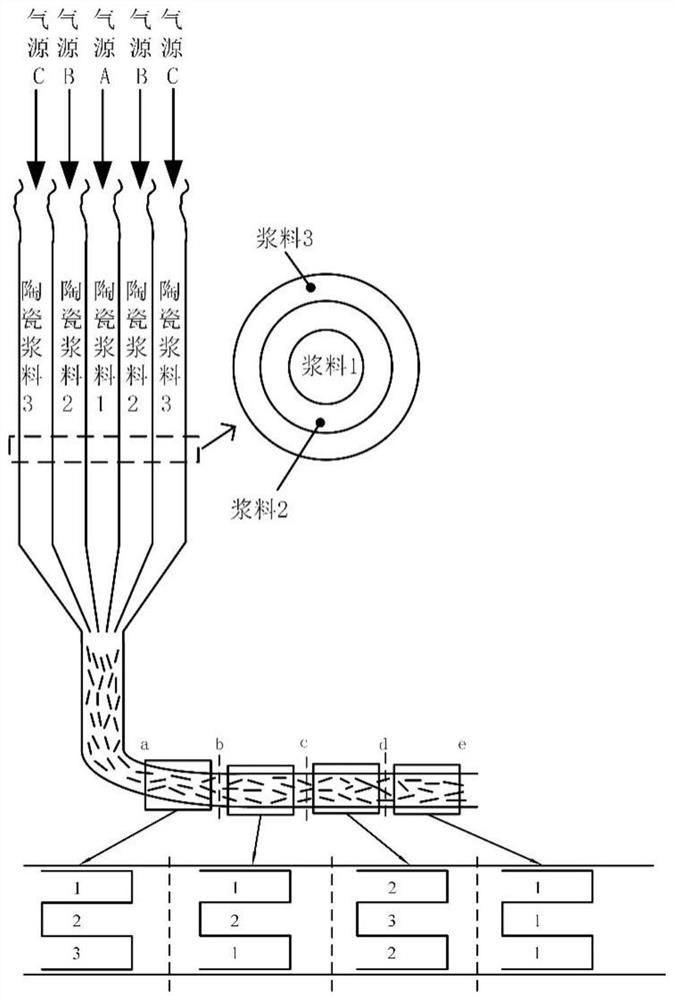

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, silicon carbide / silicon nitride / alumina functionally graded materials are prepared.

[0053] (1) Ceramic slurry preparation

[0054]Preparation of silicon carbide slurry: Weigh 60g of SiC powder, add 26g of absolute ethanol, 8g of polyethylene glycol and 1.5g of guar gum, and stir thoroughly to obtain a silicon carbide ceramic slurry with shear thinning;

[0055] Preparation of silicon nitride ceramic slurry: Weigh 65g of silicon nitride powder, add 28g of absolute ethanol, 1g of sodium hexametaphosphate and 1.8g of guar gum, and stir well to obtain a silicon nitride ceramic with shear thinning slurry;

[0056] Preparation of alumina slurry: Weigh 50g of alumina powder, add 13.2g of methyl ethyl ketone, 6.8g of absolute ethanol, 1g of glycerol trioleate and 0.8g of polyvinyl alcohol, and stir well to obtain the oxidation slurry with shear thinning. Aluminum ceramic paste;

[0057] (2) Inject the three different ceramic slurries prepared above into...

Embodiment 2

[0061] This example prepares silicon carbide / titania / zirconia functionally graded material

[0062] (1) Ceramic slurry preparation

[0063] Preparation of silicon carbide slurry: Weigh 60g of SiC powder, add 26g of absolute ethanol, 4g of polyethylene glycol, 1.2g of 25wt% tetramethylammonium hydroxide and 1.5g of guar gum to it, and stir well to obtain Shear thinned silicon carbide ceramic slurry;

[0064] Preparation of titanium dioxide ceramic slurry: Weigh 55g of titanium dioxide powder, add 19g of deionized water, 2g of ammonium methacrylate and 1.4g of guar gum carboxymethyl cellulose, and obtain a shear-thinning titanium dioxide ceramic slurry after fully stirring material;

[0065] Preparation of zirconia slurry: Weigh 50 g of zirconia powder, add 23 g of acetone, 0.8 g of polyvinyl alcohol, and 0.6 g of dibutyl phthalate, and stir thoroughly to obtain a shear-thinning zirconia ceramic slurry;

[0066] (2) The three different ceramic slurries prepared are injected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com