Hydraulic balance loading large torque static calibration device

A technology of hydraulic balance and high torque, applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, instrument, etc., can solve the problem of torque meter spindle drive system modification, affecting calibration accuracy and other problems, to reduce frictional resistance , Improve calibration accuracy and reduce the effect of variant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

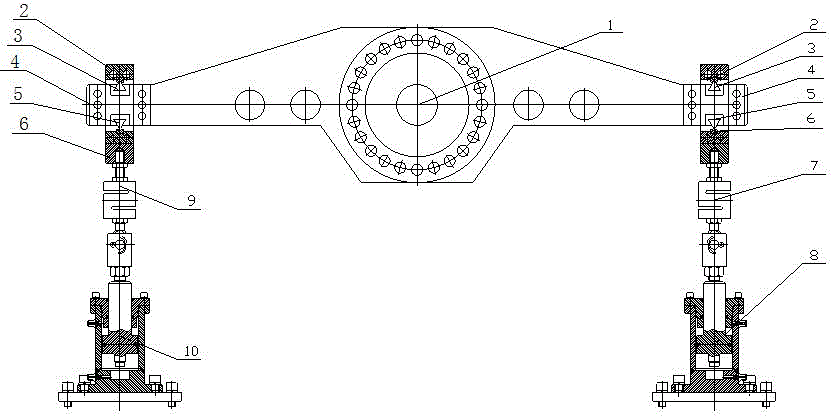

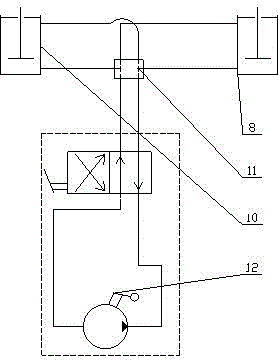

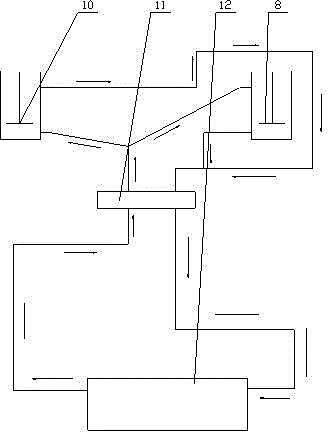

[0014] Such as figure 1 The hydraulic balance loading type high-torque static calibration device shown includes a torque meter main shaft 1, and the two ends of the torque meter main shaft 1 are symmetrically fixedly connected with a correction arm 4, and the upper and lower ends of the correction arm 4 are respectively connected with an upper triangular knife 3 and a lower The triangular knife 5, the upper triangular knife 3 is also connected with the upper V-shaped block 2, the lower triangular knife 5 is also connected with the lower V-shaped block 6, and the bottom of the lower V-shaped block 6 is provided with the first pull pressure sensor 7 and the first oil cylinder 8 , the bottom of the V-shaped block 6 at the other end is provided with a second tension pressure sensor 9 and a second oil cylinder 10, and the bases of the first oil cylinder 8 and the second oil cylinder 10 are fixed.

[0015] As can be seen from the figure, the calibration arm 4 is installed and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com