Split hydraulic clamp

A hydraulic pliers, split technology, used in hand-held tools, manufacturing tools, electrical components, etc., can solve the problems of poor pressure bearing effect, waste of materials, looseness and deformation, etc., to achieve center alignment, convenient transportation, and small deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

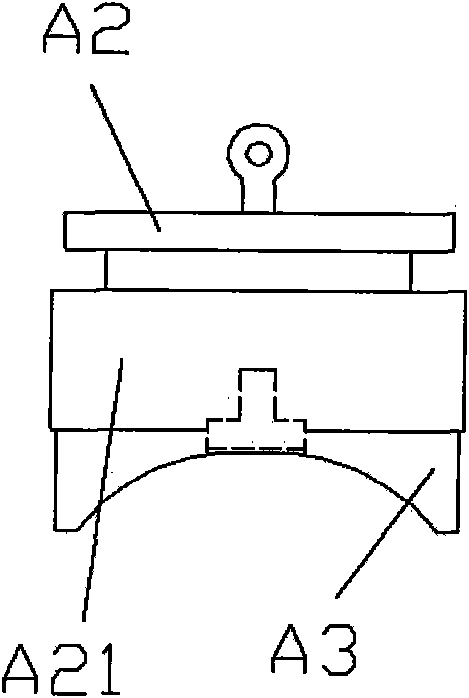

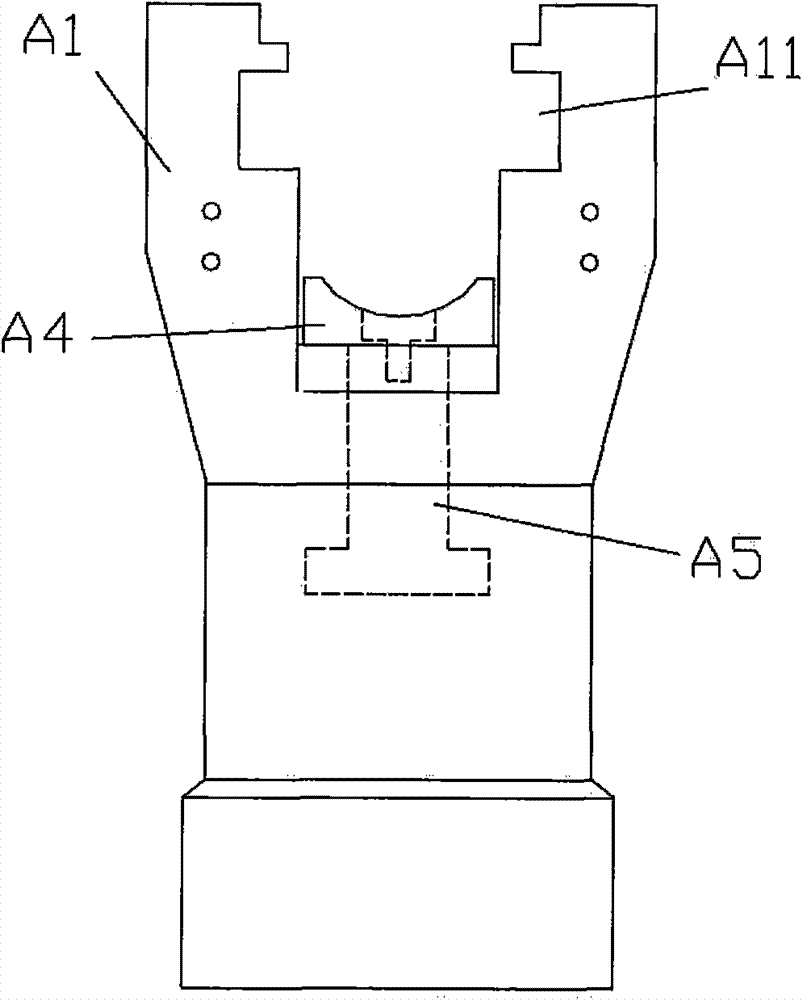

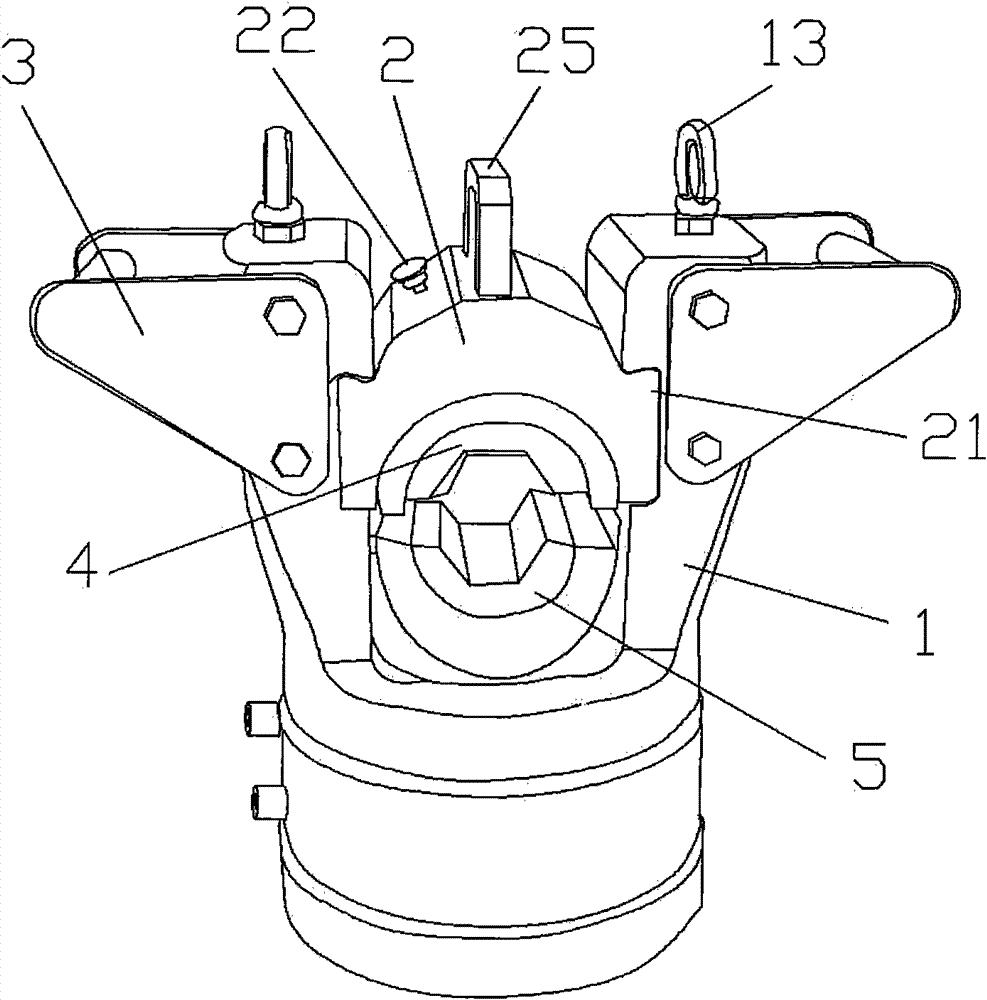

[0035] Examples, see Figure 3 to Figure 10 Shown: a split hydraulic pliers, including caliper body 1, pliers upper cover 2, handle 3, upper mold 4, lower mold 5 and piston 6, the piston is installed on the caliper body 1, and the caliper body 1 is fixedly connected with The handle 3 and the pliers body 1 are formed with a guide groove 11, and the corresponding pliers upper cover 2 is formed with a guide post 21, and the guide post 21 is inserted into the guide groove 11, and the pliers upper cover 2 is formed with a pliers upper cover positioning hole 23 , the positioning spring pin 22 of the upper mold and the upper cover of the clamp is installed;

[0036] The pliers body 1 is equipped with a pliers upper cover and a pliers body positioning spring pin 12, and the pliers upper cover and pliers body positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com