A die forging method for an output shaft of a gearbox

A technology for output shafts and gearboxes, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, mechanical equipment, etc., can solve the problems of easy fracture, short service life, incomplete heat treatment, etc. Easy to break and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

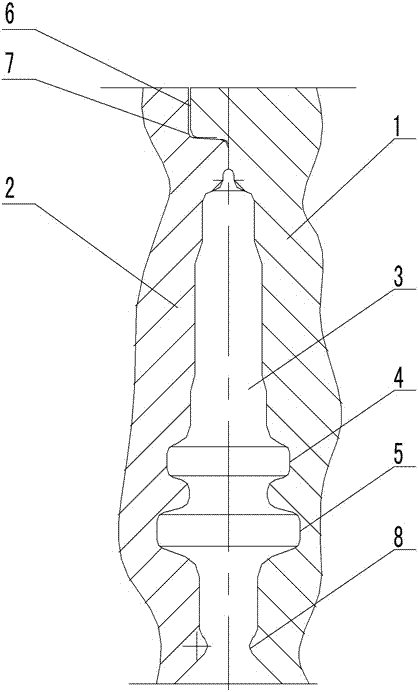

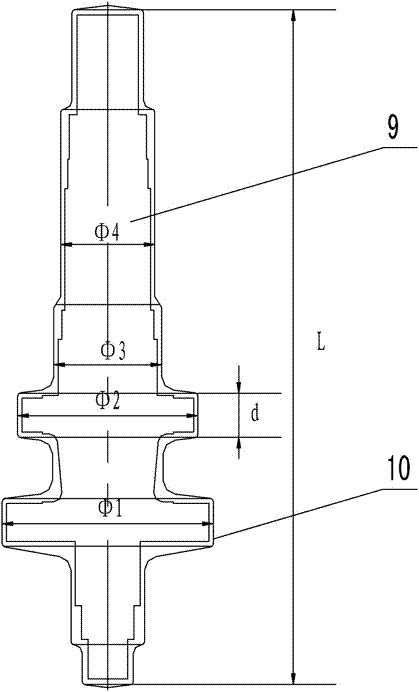

[0023] Embodiment: A kind of die forging method of gear box output shaft of this example, its steps are:

[0024] a. 20MnCr5 alloy steel billet is selected, the composition and percentage of alloy steel are: carbon 0.17-0.22%, silicon ≤ 0.12%, manganese 1.10-1.50%, phosphorus ≤ 0.035%, sulfur 0.020-0.035%, chromium 1.00-1.30%, copper ≤ 0.20%, aluminum 0.020-0.055%, the matrix is iron, its low-power structure is generally loose, the center is loose, and the segregation is ≤3 grades, the banded structure is ≤3 grades, the purity K3 (O)<30, austenite crystal The particle size is not more than 5.0 grade, and the end hardenability J10=33-39; the blank is cut with a semi-automatic band sawing machine, and the diameter of the blank is 100mm;

[0025] b. Put the billet into the natural gas heating furnace for heat treatment: first heat the billet to 1170°C, then rapidly cool down to 1000°C, the cooling rate is 5°C / s, then heat the billet to 1200°C, and then rapidly cool down to 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com