Process for producing pillowcase not obliquely kneaded after being filled with duck down or hollow staples

A production process and hollow technology, applied in the cutting of textile materials, spreading thin soft materials, textiles and papermaking, etc., can solve the problems of rising fabric costs, affecting sales, skewing, etc., to achieve cost savings and customer satisfaction. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

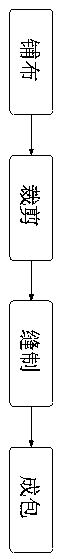

[0027] A pillowcase production process that is filled with duck down or hollow staple fibers without pinching, the process flow is as follows figure 1 , including the following steps:

[0028] Step 1: Spread the cloth. Use the conventional cloth spreading machine to spread the cloth by cutting and flipping the two-way cloth. Only two layers of fabrics are spread, and the cloth is spread in the same direction, which can ensure that the pieces formed by subsequent cutting can maintain the same direction. Adjust the tension of spreading to 80N, and adjust the speed of spreading to 60 m / min. Change the traditional spreading tension and speed to avoid wrinkles and unevenness of subsequent fabrics;

[0029] Step 2: Cutting. Lay a layer of fabric from the required length point back to the original point and then cut it. Turn the head of the spreading machine 180°, and then spread it back to the original point from the required length point to cut it. This way of spreading the fabric ...

Embodiment 2

[0034] A pillowcase production process that is filled with duck down or hollow staple fibers without pinching, the process flow is as follows figure 1 , including the following steps:

[0035] Step 1: Spread the cloth. Use the conventional cloth spreading machine to spread the cloth by cutting and flipping the two-way cloth. Only two layers of fabrics are spread, and the cloth is spread in the same direction, which can ensure that the pieces formed by subsequent cutting can maintain the same direction. Adjust the tension of spreading to 90N, and adjust the speed of spreading to 50 m / min. Change the traditional spreading tension and speed to avoid wrinkles and unevenness of subsequent fabrics;

[0036] Step 2: Cutting. Lay a layer of fabric from the required length point back to the original point and then cut it. Turn the head of the spreading machine 180°, and then spread it back to the original point from the required length point to cut it. This way of spreading the fabric ...

Embodiment 3

[0041] A pillowcase production process that is filled with duck down or hollow staple fibers without pinching, the process flow is as follows figure 1 , including the following steps:

[0042] Step 1: Spread the cloth. Use the conventional cloth spreading machine to spread the cloth by cutting and flipping the two-way cloth. Only two layers of fabrics are spread, and the cloth is spread in the same direction, which can ensure that the pieces formed by subsequent cutting can maintain the same direction. The tension of spreading is adjusted to 100N, and the speed of spreading is adjusted to 50 m / min, changing the traditional tension and speed of spreading to avoid wrinkles and unevenness of subsequent fabrics;

[0043]Step 2: Cutting. Lay a layer of fabric from the required length point back to the original point and then cut it. Turn the head of the spreading machine 180°, and then spread it back to the original point from the required length point to cut it. This way of spread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com