Roller compacted concrete dam structure and construction method

A technology of roller compacted concrete and construction method, applied in infrastructure engineering, marine engineering, water conservancy engineering and other directions, can solve problems such as cooling water leakage and cooling pipe fracture, and achieve the effect of improving support force, reducing difficulty and improving filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

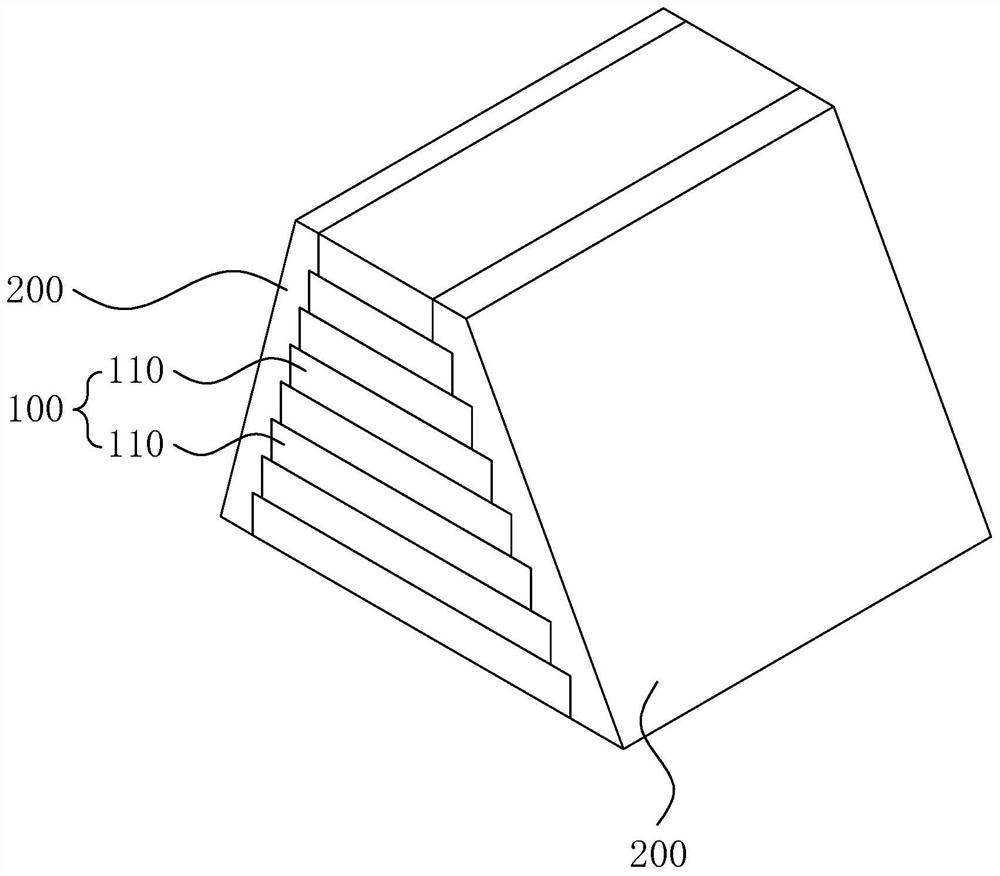

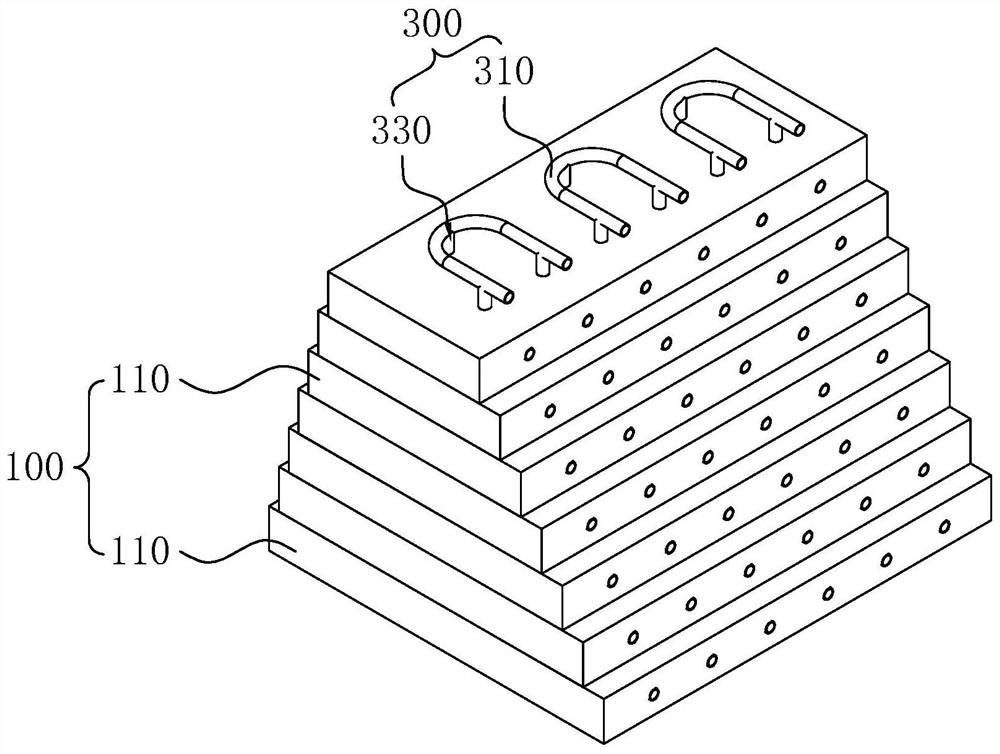

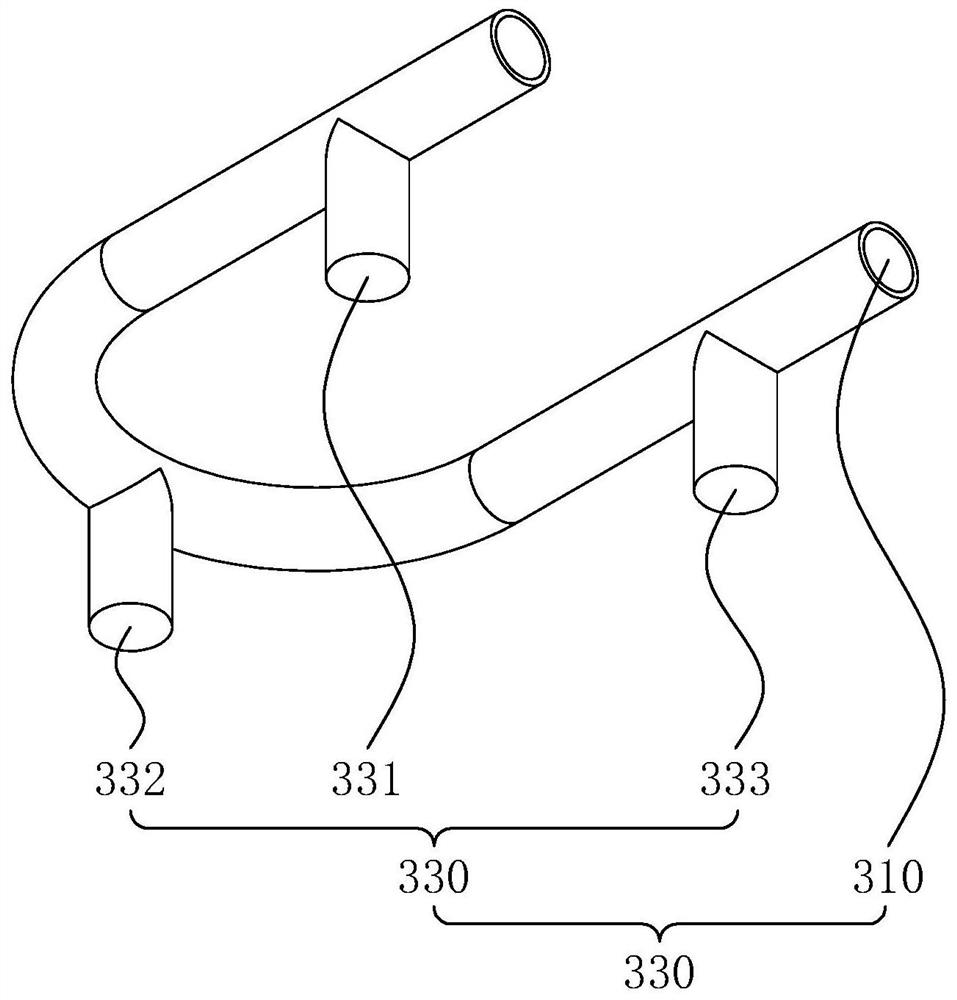

[0051] The embodiment of the application discloses a roller compacted concrete dam structure and a construction method. First, the embodiment of the present application discloses a roller compacted concrete dam structure, referring to figure 1 and figure 2 , the roller compacted concrete dam structure includes a roller compacted concrete part 100 and a normal concrete part 200 laid on both sides of the roller compacted concrete part 100, the roller compacted concrete part 100 includes a multi-layer roller compacted concrete layer 110, and the roller compacted concrete layer from bottom to top 110 The width gradually narrows. The roller compacted concrete is provided with a cooling mechanism 300 for cooling the roller compacted concrete. The cooling mechanism 300 includes a multi-section cooling pipe 310, and the multi-section cooling pipe 310 is evenly distributed in the length direction of the roller compacted concrete dam. When cooling the roller compacted concrete layer ...

Embodiment 2

[0072] The embodiment of the application discloses a roller compacted concrete dam structure and a construction method. First, the embodiment of the present application discloses a roller compacted concrete dam structure, referring to Figure 5 The difference between the embodiment of the present application and the embodiment 1 is that a metal hose 320 is used for flexible connection between adjacent cooling pipes 310 at both ends. One end of the metal hose 320 is fastened to the water outlet end of one section of the cooling pipe 310 , and the other end of the metal hose 320 is fastened to the water inlet end of an adjacent section of the cooling pipe 310 .

[0073] Under the communication effect of the metal hose 320, the cooling pipes 310 in the roller compacted concrete in the same layer are connected together. When cooling the roller compacted concrete, it is only necessary to fill the water inlet end of the cooling pipe 310 at the end, and then all the cooling pipes 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com