Continuous condensation method of perfluorinated ethylene propylene emulsion

A technology of agglomeration method and continuous method, applied in the field of continuous agglomeration of polyperfluoroethylene propylene emulsion, can solve the problems of complex process, low equipment utilization rate, unfavorable washing, continuous drying and granulation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

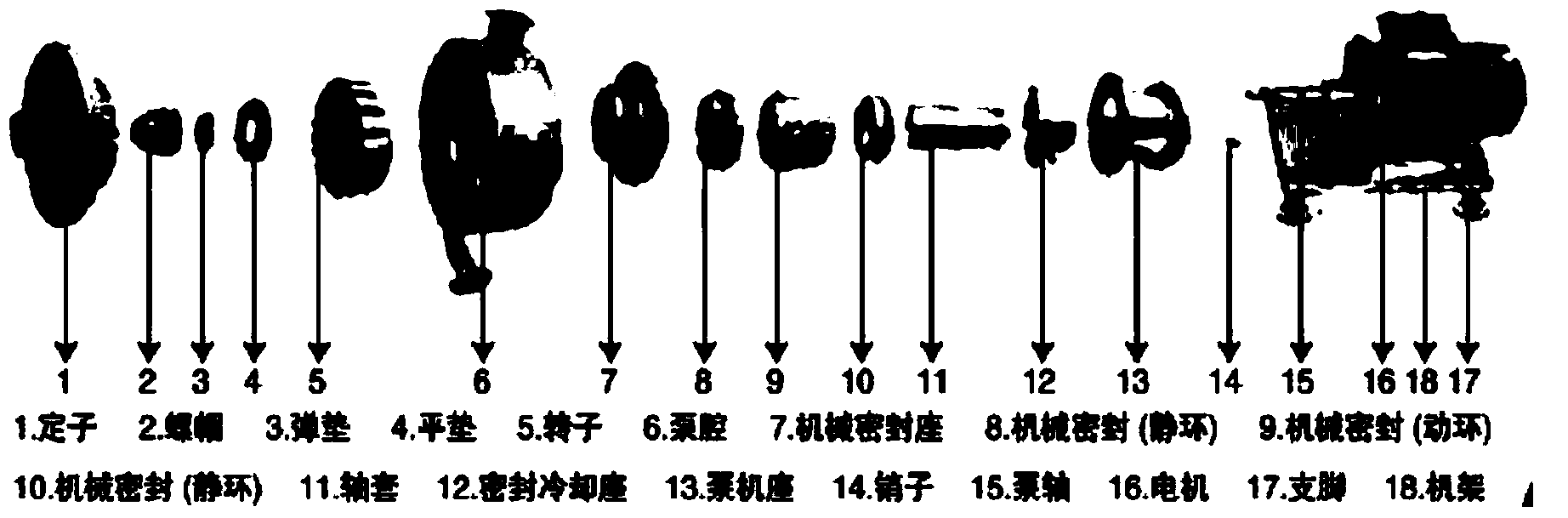

Image

Examples

Embodiment 1

[0043] 1. Preparation of polyperfluoroethylene propylene resin emulsion

[0044] Add 1600L deionized water and 1800g perfluorooctanoic acid ammonium dispersant in the 2000L autoclave, fill nitrogen gas to test the pressure without leaking, after evacuating and analyzing the oxygen content is qualified, add quantitative initial monomer (mass ratio, Wt( TFE): Wt(HFP) = about 20:80) and heat up, when the temperature reaches 100°C and the pressure reaches 3.2MPa; use a metering pump to inject 90 grams of initiator potassium persulfate into the polymerization kettle to start the reaction, use a membrane The formula pump will add additional monomer (mass ratio, Wt(TFE):Wt(HFP) = about 95:5) into the polymerization tank to keep the reaction pressure constant; when the amount of added monomer reaches the specified value, stop the reaction. The solid content of the obtained polymeric emulsion was 30 wt%, the specific gravity of the emulsion was 1.18 at 20°C, and the melt viscosity at 3...

Embodiment 2

[0048] 1. Preparation of polyperfluoroethylene propylene resin emulsion

[0049] Add 1600L deionized water and 1800g perfluorooctanoic acid ammonium dispersant in the 2000L autoclave, fill nitrogen gas to test the pressure without leaking, after evacuating and analyzing the oxygen content is qualified, add quantitative initial monomer (mass ratio, Wt( TFE): Wt(HFP) = about 30:70) and heat up, when the temperature reaches 100°C and the pressure reaches 3.2MPa; use a metering pump to inject 90 grams of initiator potassium persulfate into the polymerization kettle to start the reaction, use a membrane The formula pump will add additional monomer (mass ratio, Wt(TFE):Wt(HFP) = about 80:20) into the polymerization tank to keep the reaction pressure constant; when the amount of added monomer reaches the specified value, stop the reaction. The solid content of the obtained polymeric emulsion was 30 wt%, the specific gravity of the emulsion was 1.18 at 20°C, and the melt viscosity at ...

Embodiment 3

[0053] 1. Preparation of polyperfluoroethylene propylene resin emulsion

[0054] Add 1600L deionized water and 1800g perfluorooctanoic acid ammonium dispersant in the 2000L autoclave, fill nitrogen gas to test the pressure without leaking, after evacuating and analyzing the oxygen content is qualified, add quantitative initial monomer (mass ratio, Wt( TFE): Wt(HFP) = about 25:75) and heat up, when the temperature reaches 100°C and the pressure reaches 3.2MPa; use a metering pump to inject 90 grams of initiator potassium persulfate into the polymerization kettle to start the reaction. The formula pump will add additional monomer (mass ratio, Wt(TFE):Wt(HFP) = about 85:25) into the polymerization tank to keep the reaction pressure constant; when the amount of added monomer reaches the specified value, stop the reaction. The solid content of the obtained polymeric emulsion was 30 wt%, the specific gravity of the emulsion was 1.18 at 20°C, and the melt viscosity at 372°C was 100 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com