Door pocket capable of being cut and clamped and provided with fixing step

A technology for fixing steps and door casings, applied in the direction of window/door frames, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

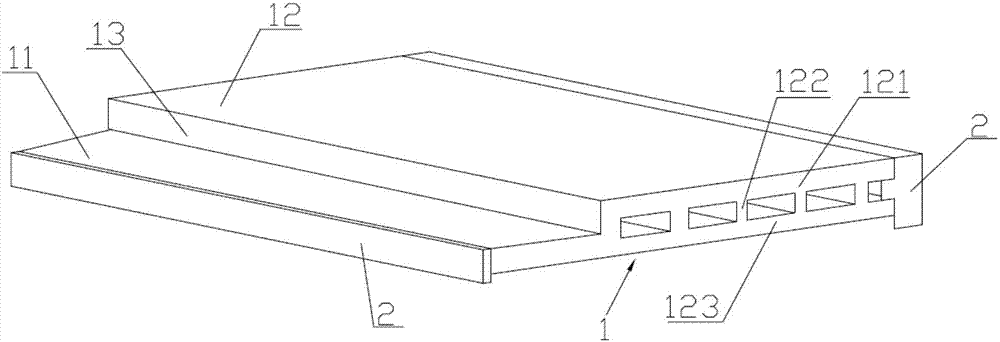

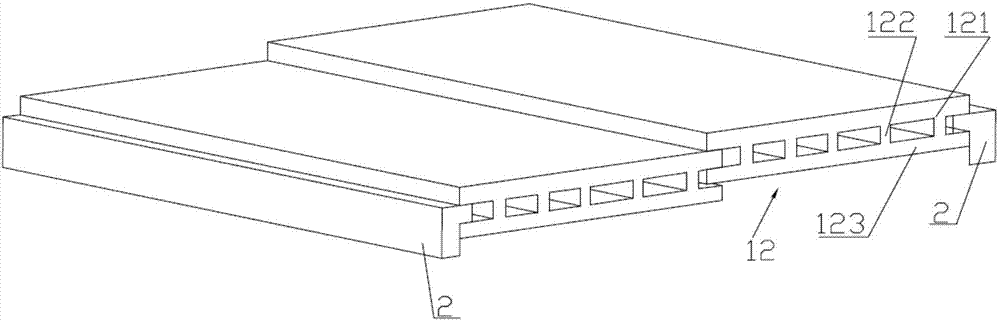

[0037] Please refer to figure 1 and figure 2 , The first preferred embodiment of the cut-and-engageable door casing with fixed steps of the present invention includes: a casing plate 1 and a line 2 .

[0038] Specifically, Line 2 includes pinned lines and non-plug-in lines.

[0039] The cover plate 1 is composed of an integrally formed front cover plate 12 and a rear cover plate 11. The front cover plate 11 and the rear cover plate 12 form a fixed step 13 at the joint, and the front cover plate 12 is higher than the rear cover at the fixed step 13. The size of the plate 11 is 8 mm to 12 mm.

[0040] The front cover plate 12 includes a surface layer 121, several first connecting ribs 122 and a bottom layer 123, the surface layer 121 and the bottom layer 123 are connected by several first connecting ribs 122, the inner surface of the surface layer 121 and the bottom layer 123 The inner surfaces are parallel, so that between the surface layer 121 and the bottom layer 123, the...

Embodiment 2

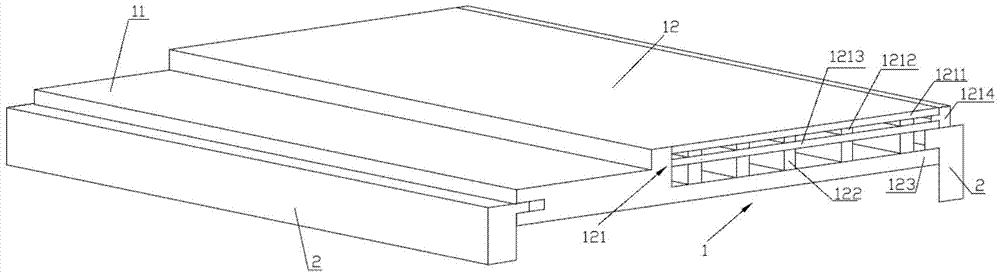

[0049] Please refer to image 3 as well as Figure 4 The second preferred embodiment of the door cover with a fixed step that can be cut and engaged in the present invention is more advanced to solve the problem of brushing the side surface of the cut front cover plate 12 of the first preferred embodiment. The problem that the abdication cannot be closed when the paint or on-site installation is cut and snapped.

[0050] In this embodiment, the door casing with a fixed step that can be cut and engaged includes: a casing plate 1 and a line 2 .

[0051] Specifically, the line 2 is an L-shaped line, and it can be understood that the line 2 can also be other lines with pins on the edges.

[0052] The cover plate 1 is composed of an integrally formed front cover plate 12 and a rear cover plate 11. The front cover plate 11 and the rear cover plate 12 form a fixed step at the joint, and the front cover plate 12 is higher than the rear cover at the fixed step. The size of the plate...

Embodiment 3

[0062] Please refer to Figure 5 Compared with the second preferred embodiment, the third preferred embodiment of the door cover with a fixed step that can be cut and engaged in the present invention further solves the problem that the thickness of the door is 40mm±20mm, and it is required to carry out the rear cover plate 11 Cut so that the cut rear cover plate 11 matches the thickness of the door.

[0063] In this embodiment, the door casing with a fixed step that can be cut and engaged includes: a casing plate 1 and a line 2 .

[0064] Specifically, the line 2 is an L-shaped line, and it can be understood that the line 2 may also be other lines with pins on the edges.

[0065] The cover plate 1 is composed of an integrally formed front cover plate 12 and a rear cover plate 11. The front cover plate 11 and the rear cover plate 12 form a fixed step at the joint, and the front cover plate 12 is higher than the rear cover at the fixed step. The size of the plate 11 is 8 mm to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com