Degradable phase change composite fiber and preparation method thereof

A composite fiber, phase change technology, applied in the chemical characteristics of fibers, rayon manufacturing, conjugated synthetic polymer rayon, etc., can solve the problem of easy overflow of phase change materials, improve energy storage efficiency, and reduce raw material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

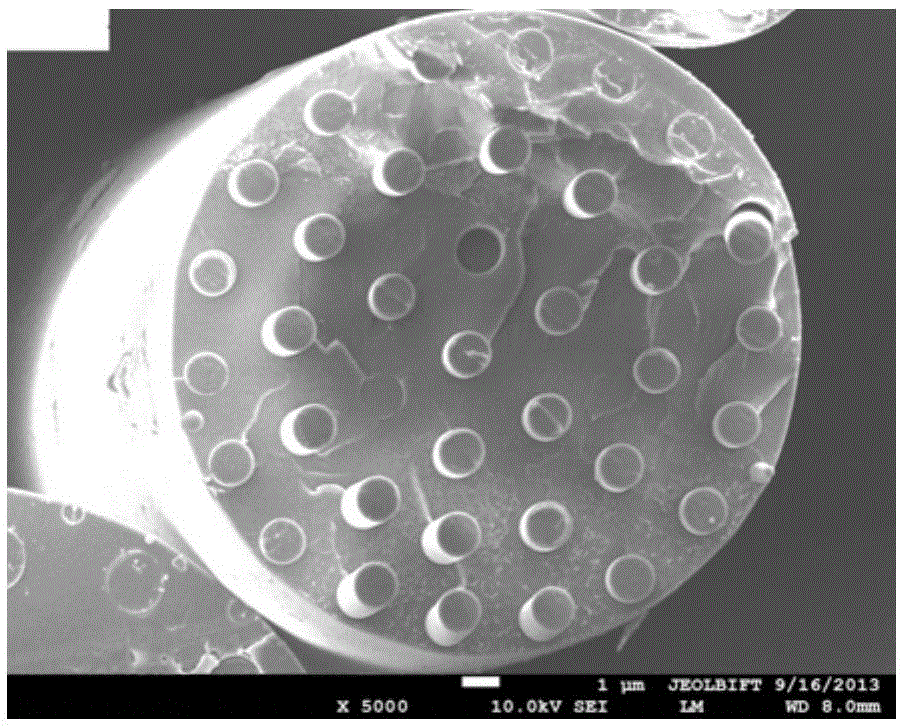

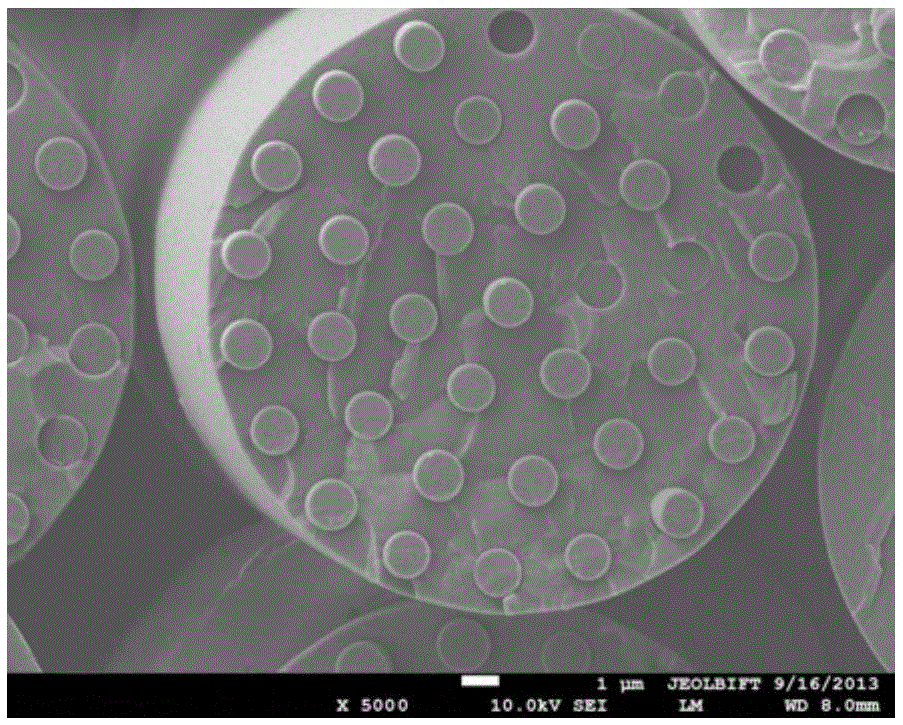

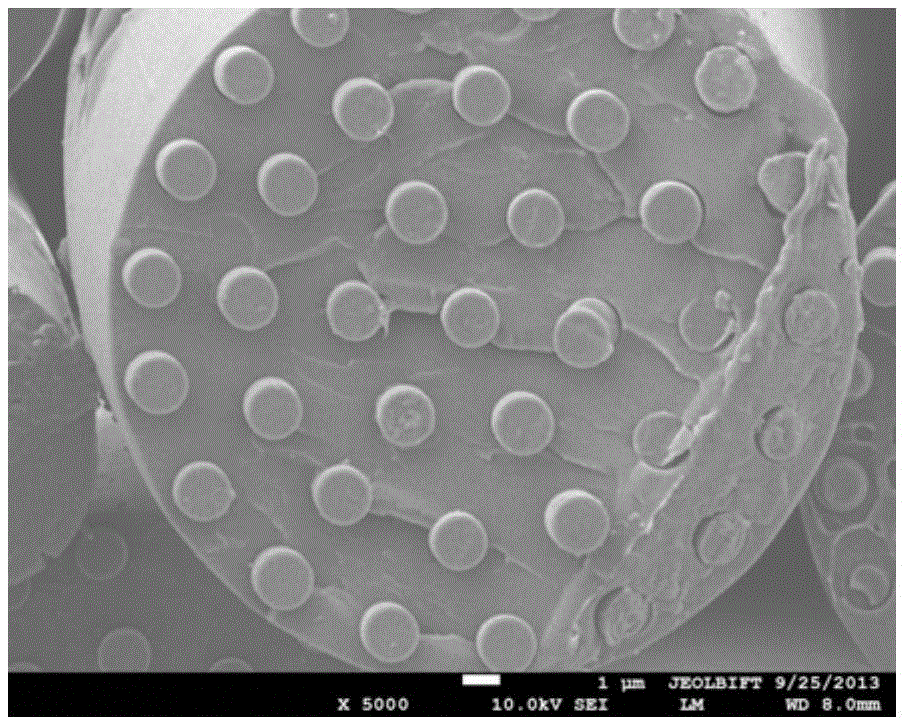

Image

Examples

preparation example Construction

[0032] In the preparation of the degradable phase change composite fiber, the steps include:

[0033] Preparation of phase change material sealing agent;

[0034] Mixing the phase change material blocking agent and polyethylene glycol to prepare a suspension;

[0035] The suspension is sent to the spinneret assembly through the conveying pipeline of melt spinning;

[0036] Spinning-grade polylactic acid is fed into the spinneret assembly by a melt-spun screw extruder;

[0037] spinning.

[0038] Use terephthalic acid and ethylene glycol as sealing agents to form a uniform suspension with phase change materials and spray them out from the spinneret hole. By physical means, the uniformly dispersed sealing agent solidifies and seals the phase change materials uniformly to form along the longitudinal direction of the fiber. Uniformly distributed large capsules of phase change materials solve the problem of closure of phase change materials in phase change composite fibers, and ...

Embodiment 1

[0072] Stir terephthalic acid and ethylene glycol with a molar ratio (the ratio of the amount of substances) of 1:1.10 at room temperature, and continuously add them to the polyethylene terephthalate prepolymer in the molten state. React at 255° C. for 2 hours to obtain a phase change material sealing agent. After the phase change material sealing agent is cooled, it is ball-milled in a ball mill for 60 minutes to obtain a granular sealing agent. Add granular blocking agent and nucleating agent nano-titanium dioxide (0.3% of the total mass of blocking agent and polyethylene glycol) into molten polyethylene glycol, and mix evenly at 90°C to obtain a suspension with a concentration of polyethylene glycol 600 of 80%. liquid. The obtained suspension is added to the phase change material storage tank, transported to the metering pump through the delivery pipeline, and quantitatively transported to the spinneret assembly by the metering pump. Spinning-grade polylactic acid is adde...

Embodiment 2

[0074] Stir terephthalic acid and ethylene glycol with a molar ratio (the ratio of the amount of substances) of 1:1.20 at room temperature, and continuously add them to the molten polyethylene terephthalate prepolymer. React at 255° C. for 2 hours to obtain a phase change material sealing agent. After the phase change material sealing agent is cooled, it is ball-milled in a ball mill for 50 minutes to obtain a granular sealing agent. Add granular blocking agent and nucleating agent nano-titanium dioxide (0.2% of the total mass of blocking agent and polyethylene glycol) into molten polyethylene glycol, and mix uniformly at 90°C to obtain a suspension with a concentration of polyethylene glycol 600 of 80%. liquid. The obtained suspension is added to the phase change material storage tank, transported to the metering pump through the delivery pipeline, and quantitatively transported to the spinneret assembly by the metering pump. The mass composite ratio of the suspension to sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com