Honeycomb core for active cooling structure and preparation method thereof

An active cooling, honeycomb core technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of weak rigid structure, cannot directly realize active cooling medium flow, difficult and other problems, achieve low density, cooling Good effect, high compressive strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

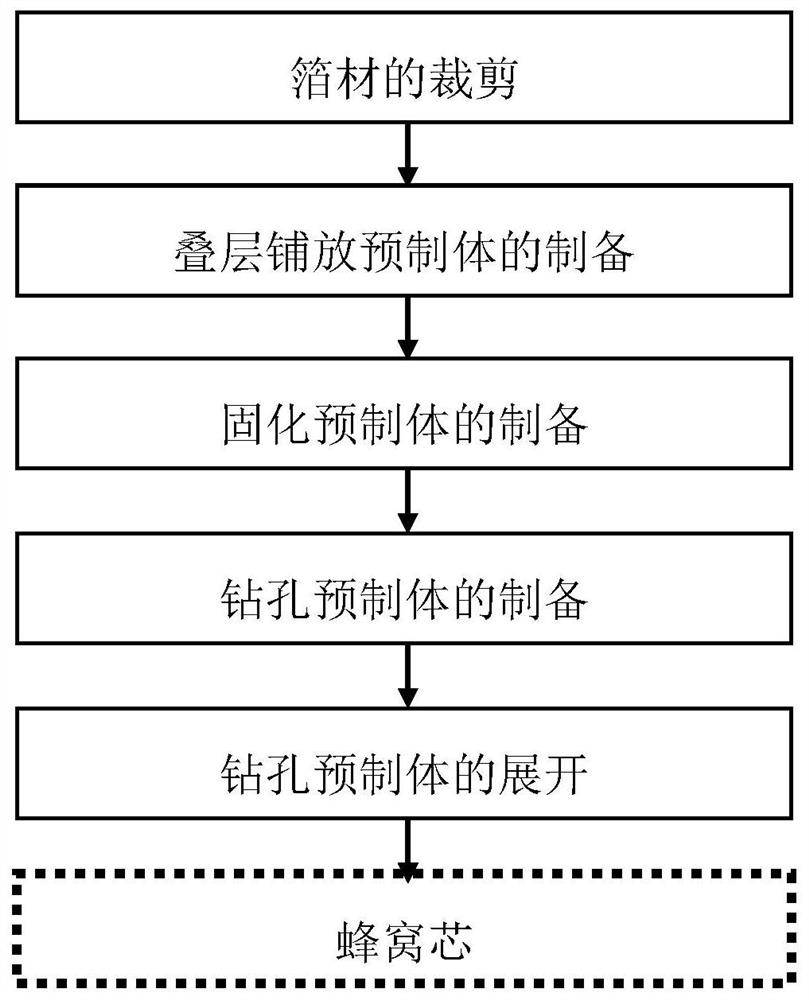

[0022] now refer to figure 1 , in which is shown a process flow diagram showing a method of manufacturing a honeycomb core for an actively cooled structure of the present invention. The preparation method of the present invention comprises five steps including cutting of the foil material, preparation of a laminated preform, preparation of a solidified preform, preparation of a drilled preform and unfolding of the drilled preform. Through the above five steps, the honeycomb core is thus produced.

[0023] Specifically, as described above, the present invention provides, in a first aspect, a method for preparing a honeycomb core for an actively cooled structure, the method comprising the following steps:

[0024] (1) Foil cutting: cut the foil according to the required size and quantity for subsequent laying;

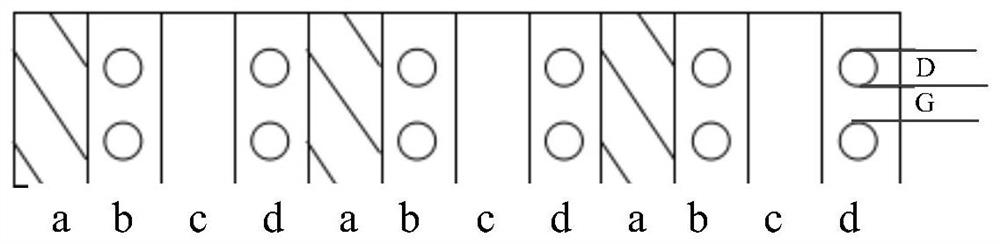

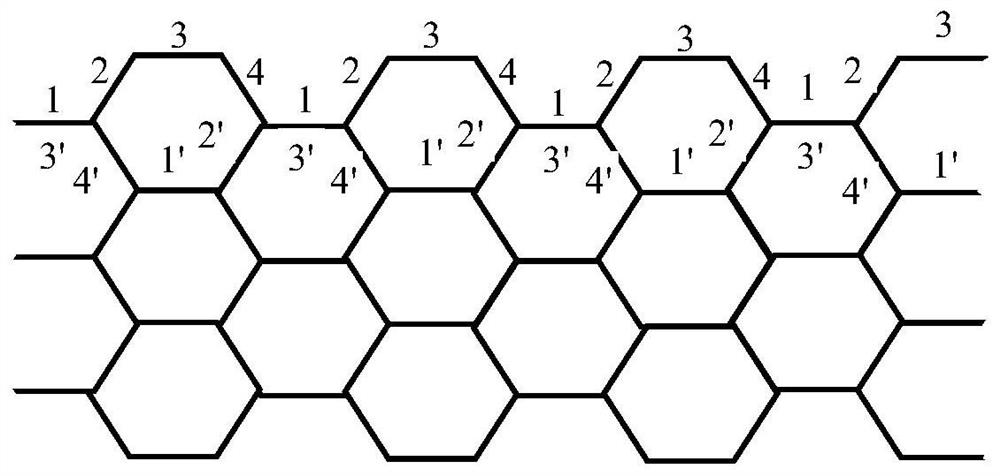

[0025] (2) Preparation of laminated prefabricated body: glue is applied from the edge of the first layer of foil, the width W of the glue is equal to the length of the...

Embodiment 1

[0054] according to figure 1 As shown in the process flow chart, the preparation of the aluminum honeycomb core for actively cooling the load-carrying structure with a cell side length of 5mm is completed, and the process includes the following steps:

[0055] Step 1: Cutting the Foil

[0056] The aluminum alloy foil is cut into foils of the same size for later use. The grade of the aluminum alloy foil is 5A02, the thickness is 0.1mm, and the size is 20mm*1000mm (this size is used in all embodiments and comparative examples);

[0057] Step 2: Preparation of laminated prefabricated body

[0058] Apply glue from the edge of the first layer of aluminum alloy foil, with a width of 5mm and a distance of 15mm. The second layer of aluminum alloy foil is aligned with the edge of the first layer and laid on the first layer of aluminum alloy Glue on the foils and glue them together; start to apply glue at a distance of 10mm from the edge of the second layer of aluminum alloy foil, wit...

Embodiment 2

[0065] according to figure 1 The process flow chart shown completes the preparation of a titanium honeycomb core with a side length of 5 mm for active cooling of the load-carrying structure. The process includes the following steps:

[0066] Step 1: Cutting of the core layer

[0067] Cut the titanium alloy foil into the same size for later use, the grade of the titanium alloy foil is TA1, and the thickness is 0.06mm;

[0068] Step 2: Preparation of laminated prefabricated body

[0069] Apply glue from the edge of the first layer of titanium alloy foil with an adhesive width of 5 mm and a gap of 15 mm. The second layer of titanium alloy foil is aligned with the edge of the first layer and laid on the first layer of titanium alloy Glue on the foils and glue them together; apply glue from the second layer of titanium alloy foil at a distance of 10mm from the edge, with a glue width of 5mm and a glue interval of 15mm; after that, odd-numbered layers of titanium alloy foils will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com