A mop chassis and a dehydration bucket fixing seat used in conjunction with it

A fixed seat and chassis technology, which is applied in the field of mop buckets, can solve the problems of one-way bearings and base springs that are fragile, reduce service life, and short service life, so as to reduce the time for cleaning the drive shaft, prolong the service life, and operate humanely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

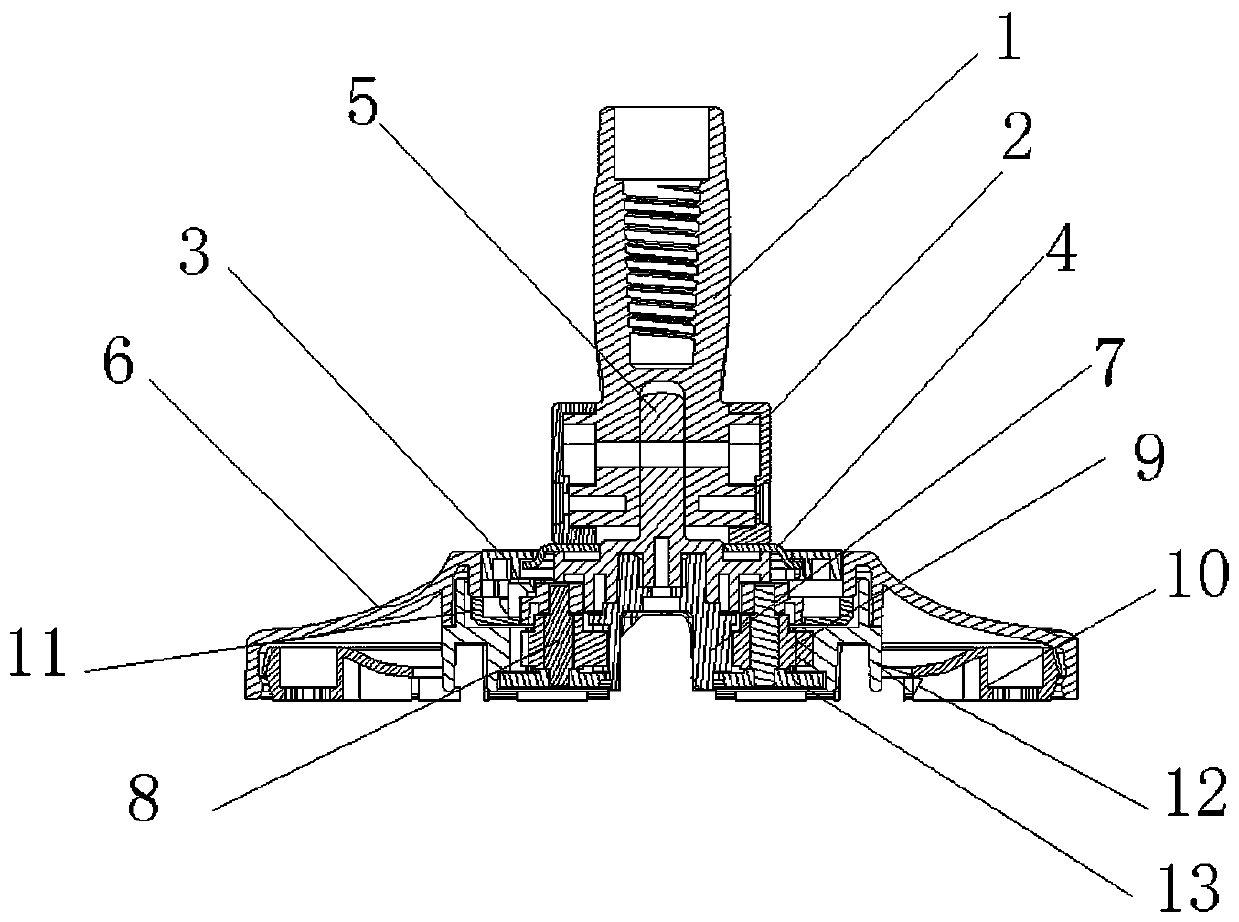

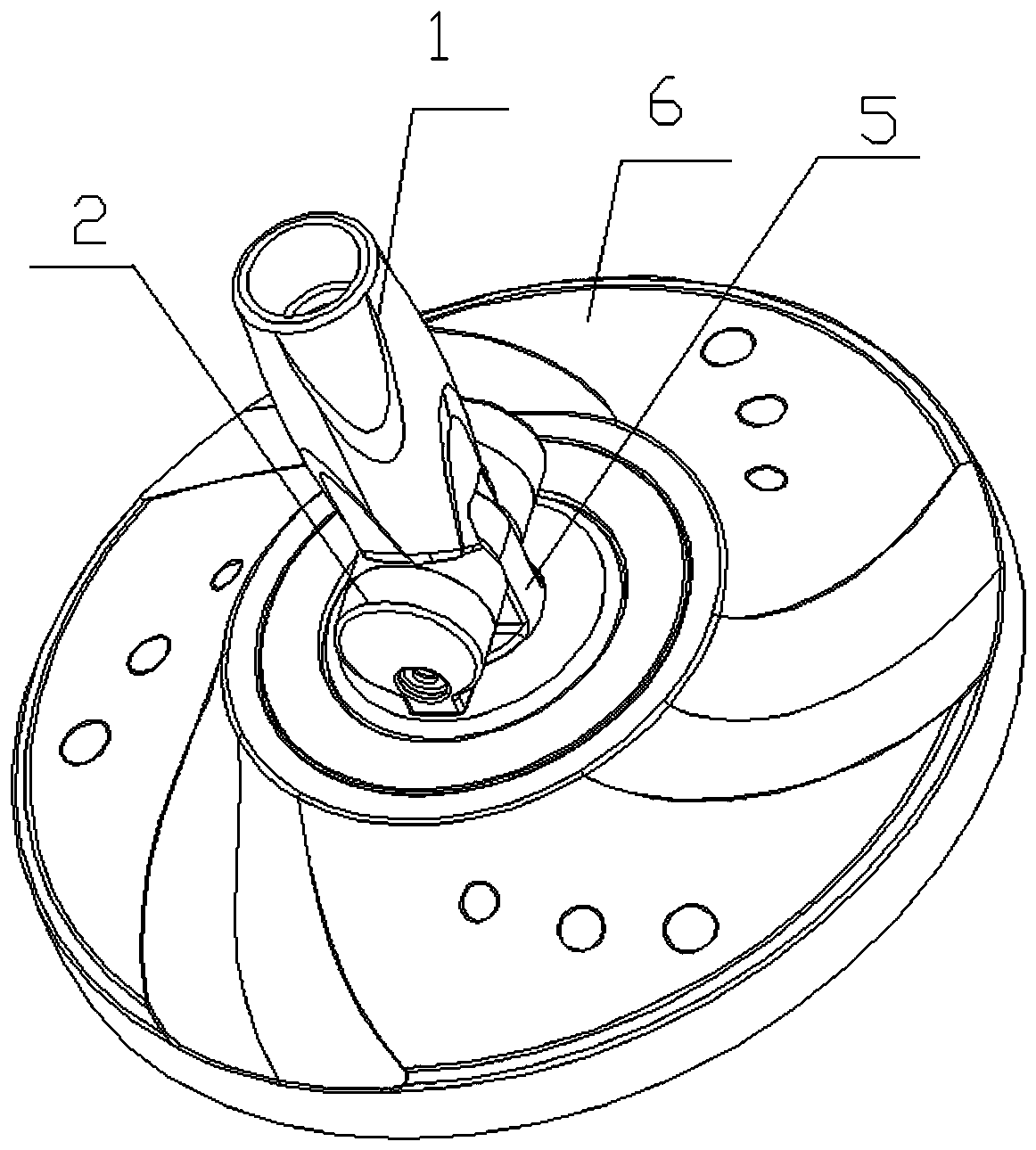

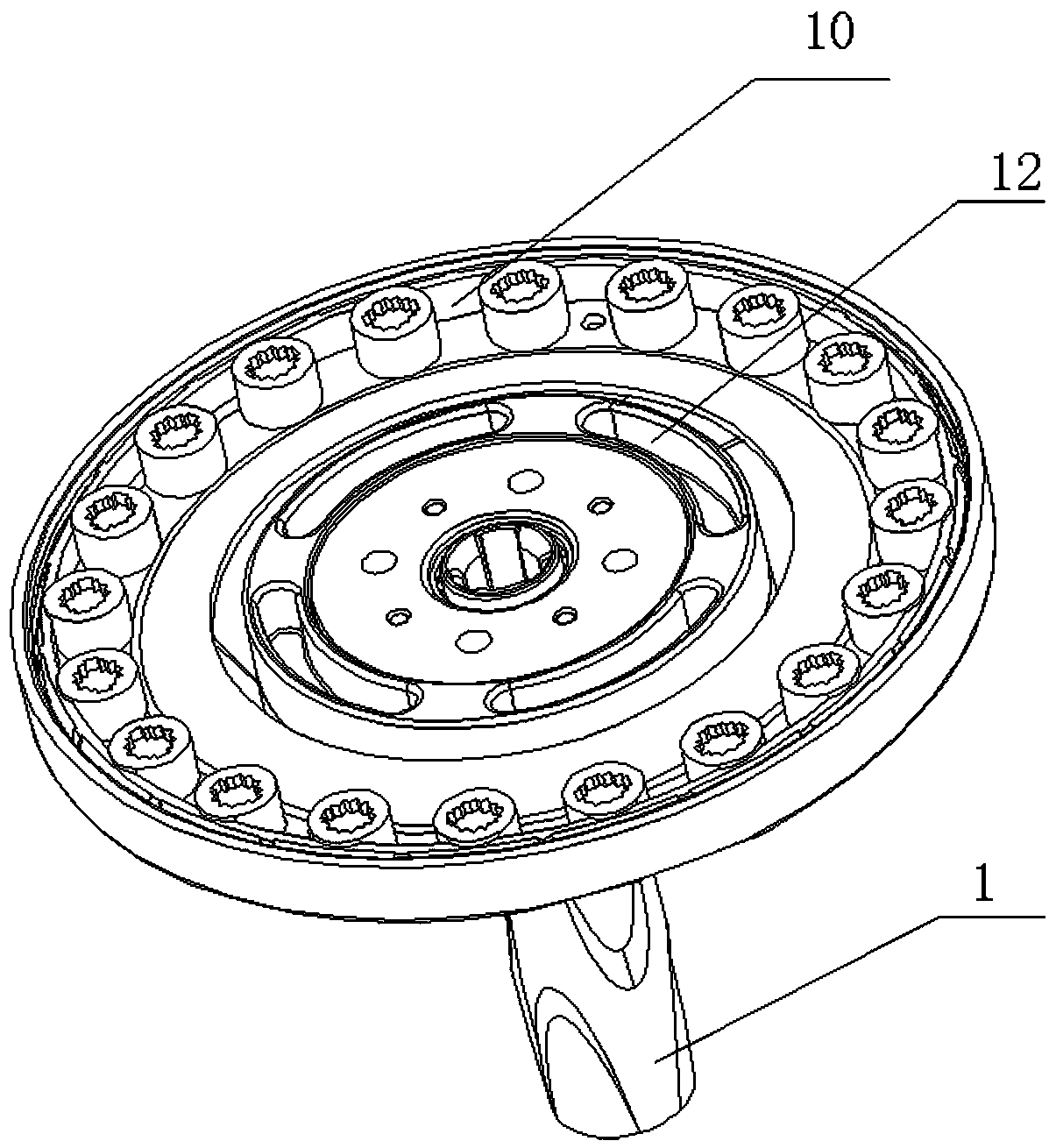

[0026] Such as Figure 1~4 As shown, the mop chassis provided in this embodiment includes: a turntable frame 1, a rotating positioning core 5, a cotton yarn turntable cover 6, a cotton yarn turntable bottom 10, and a speed reduction mechanism. The turntable frame 1 is connected with the rotating positioning core 5, and the rotating positioning core 5 is connected to the cotton yarn turntable cover 6, and the bottom of the cotton yarn turntable is clamped on the inner cover of the cotton yarn turntable cover. The bottom of the cotton yarn turntable is used to fix the cotton yarn. The mechanism is connected with the rotary positioning core 5 . In this embodiment, the deceleration mechanism is specifically: comprising a deceleration gear 7, a deceleration pinion 9, and a deceleration internal gear 12, the deceleration gear 7 is connected with the rotating positioning core 5, the deceleration gear 7 and the deceleration pinion 9 mesh, and the deceleration pinion 9 meshes with the...

Embodiment 2

[0032] Such as Figure 5 As shown, the present embodiment provides a dehydration bucket fixing base that matches the above-mentioned mop chassis. The fixing base includes a base 18, a dehydration net drive shaft 15 and a fixing device for fixing the deceleration internal gear. A groove is arranged in the middle of the base, and the groove The dehydration net transmission shaft 15 is arranged inside, and a positioning joint 14 is assembled above the dehydration net transmission shaft 15. It is an interference fit between the dehydration net transmission shaft 15 and the positioning joint 14, and the positioning joint 14 cooperates with the speed reduction mechanism in the mop chassis; The fixing device for fixing the decelerating internal gear in the embodiment is the boss 19 arranged above the base, and the protruding post 19 can be inserted into the groove of the decelerating internal gear to fix the decelerating internal gear, so as to decelerate the rotation of the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com