A kind of electrostatic precipitator and its cleaning mechanism

A technology of cleaning mechanism and electrostatic precipitator, applied in electrode cleaning, external electrostatic separator, electrostatic separation, etc., can solve the problems of high manufacturing, operation and maintenance costs, unadjustable matching gap between the cleaning brush and the dust collecting surface, etc. , to achieve the effect of eliminating the risk of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

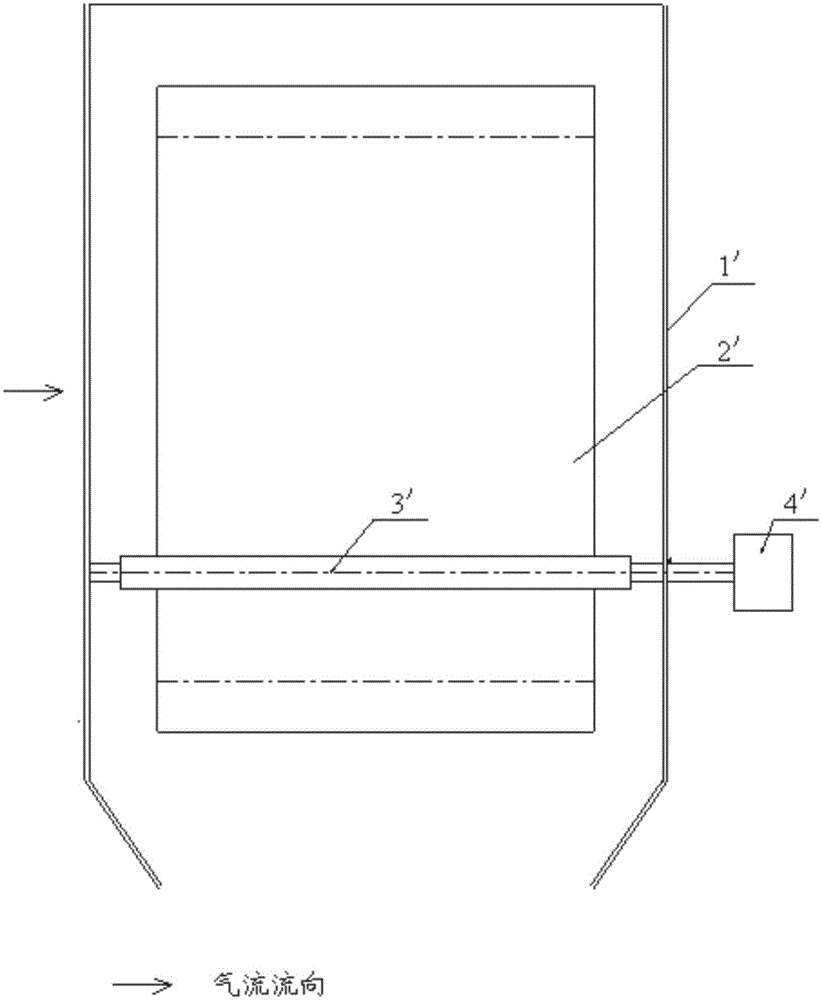

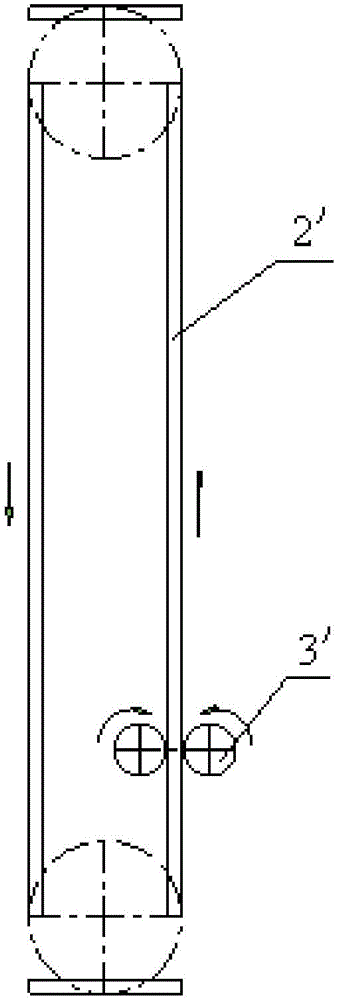

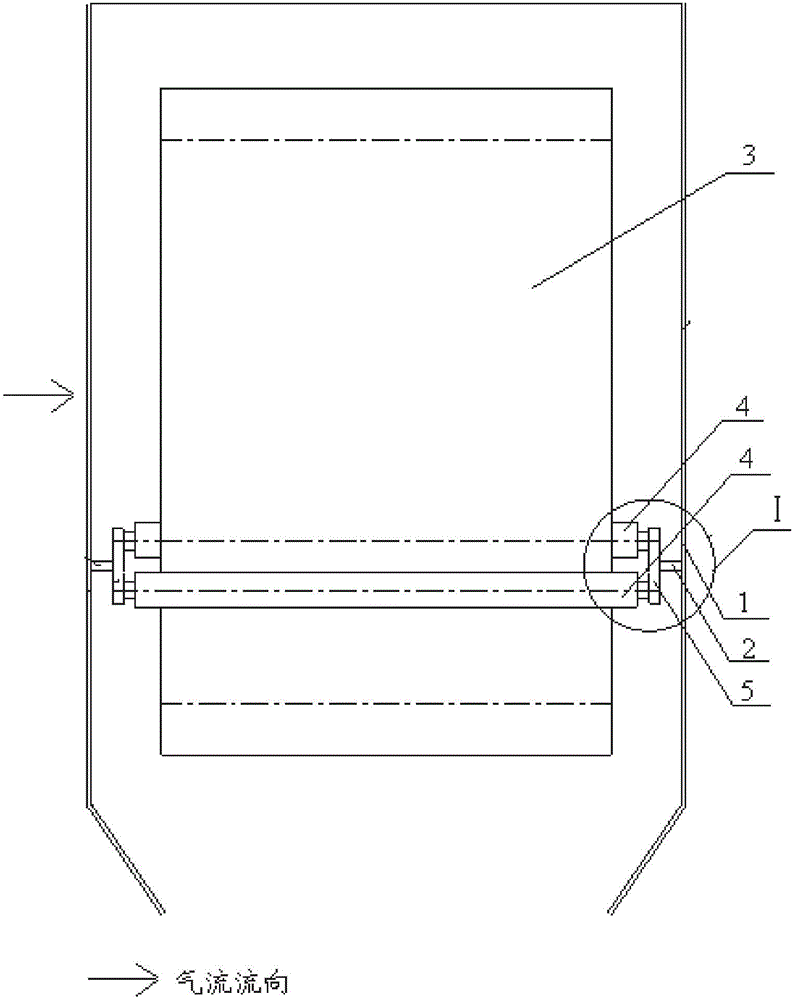

[0031] The core of the present invention is to provide a dust removal mechanism for an electrostatic precipitator, so that two dust removal brushes are respectively arranged at both ends of the pivot joint, and the pivot joint is pivotally connected to the housing through a pivot shaft, and the The principle of leverage makes the moment of one of the dust cleaning brushes on the pivot shaft greater than the other, so that the dust cleaning brush is always offset against the dust collection surface on the corresponding side of the dust collection anode, thereby solving the manufacturing, operation and maintenance costs of the existing dust cleaning mechanism High, and after the dust-cleaning brush wears out, it is impossible to adjust the gap between the dust-collecting surface of the dust-collecting anode plate and the dust-cleaning brush.

[0032] Without loss of generality, the specific embodiment of the cleaning mechanism provided by the present invention will be described b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com