A carbon fiber composite mechanical arm molding method

A robotic arm and composite material technology, which is applied in the field of automatic operation equipment, can solve the problems that the product quality cannot be guaranteed, the molding pressure cannot be accurately controlled, and the use cost is high, so as to avoid the generation of waste of auxiliary consumables, eliminate the risk of air bag leakage, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

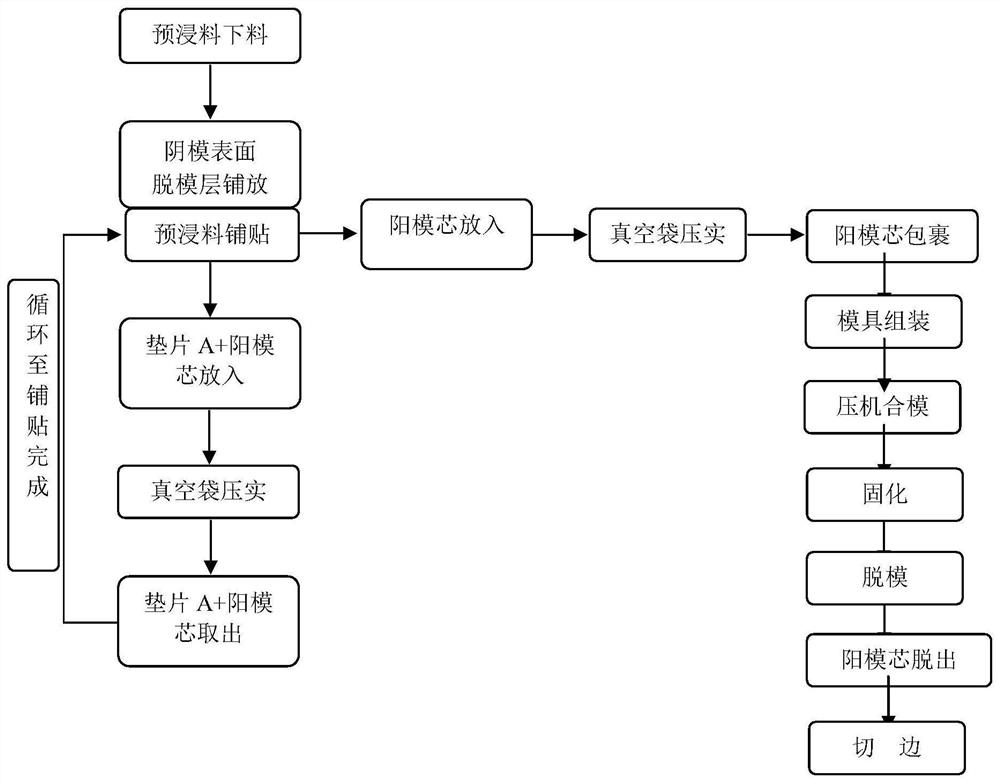

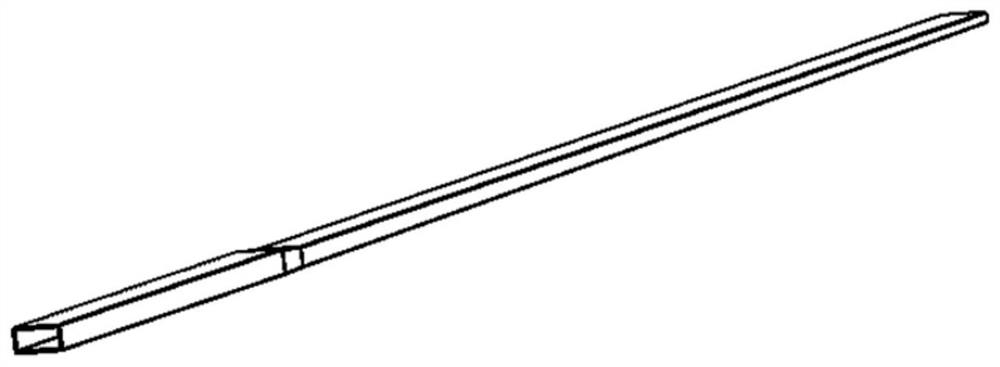

[0029] The mechanical arm in the carbon fiber composite mechanical arm molding method of the present invention is a hollow tube with a rectangular cross-section, a length of 2450-2550mm, and a wall thickness of 2-4mm. image 3 As shown, the steps of the molding method are as follows:

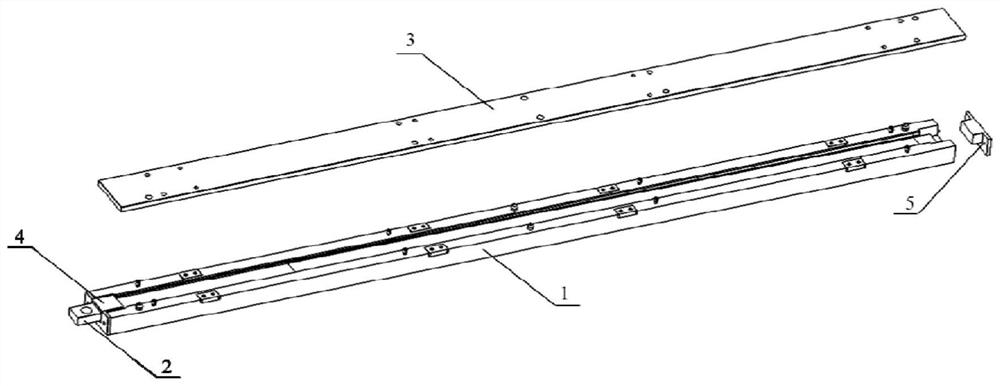

[0030] Step 1, processing molding mold: such as figure 2 As shown, the mold includes a steel female mold 1 and a male mold core 2. The female mold 1 is a U-shaped strip structure, and its U-shaped cavity shape controls the outer dimensions of the product. The strip-shaped male mold core 2 is used to form the hollow structure of the hollow tube of the mechanical arm, and an annular gland 4 set on one end of the male mold core 2 is set at one end of the cavity of the female mold 1U to seal the female mold The gap between the 1U-shaped mold cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com