Compaction system for inclined plane for connecting engine exhaust manifold with cylinder cover

An exhaust manifold and engine technology, which is applied to engine components, machines/engines, exhaust devices, etc., can solve problems such as loose connections, air leakage in the exhaust system, and deformation of the exhaust manifold, so as to eliminate air leakage, Solve deformation and air leakage, reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

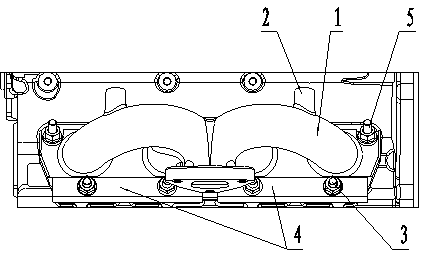

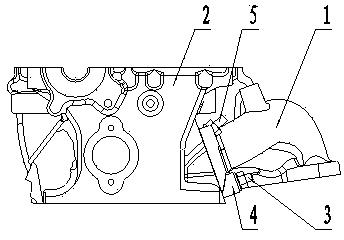

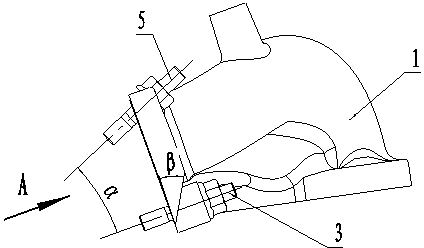

[0020] See Figure 1, Figure 2, image 3 , Figure 4 , the present invention includes an exhaust manifold 1 and an exhaust manifold pressure block 4, and its special feature is that the installation surface of the exhaust manifold mounting flange is a plane that fits the cylinder head 2, and the exhaust manifold The upper part of the back of the pipe installation flange is provided with not less than five exhaust manifold stud installation positioning holes, and the lower part of the back of the exhaust manifold installation flange is a slope structure, and the angle between the slope and the installation surface is β. There are not less than four positioning grooves 6 on the inclined surface. The exhaust system is assembled with the exhaust manifold pressing block 4 through the positioning grooves 6, and then fixed to the cylinder head 2 through the exhaust manifold mounting studs 5. superior.

[0021] See Figure 1, figure 2 , image 3 , Figure 5 , the exhaust manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com