Automatic casting device and casting method for casting to mold

A technology of automatic pouring and casting, which is used in foundry equipment, casting melt containers, equipment supplying molten metal, etc. The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, in order to explain the present invention more specifically, embodiments of the present invention will be described in detail with reference to the drawings.

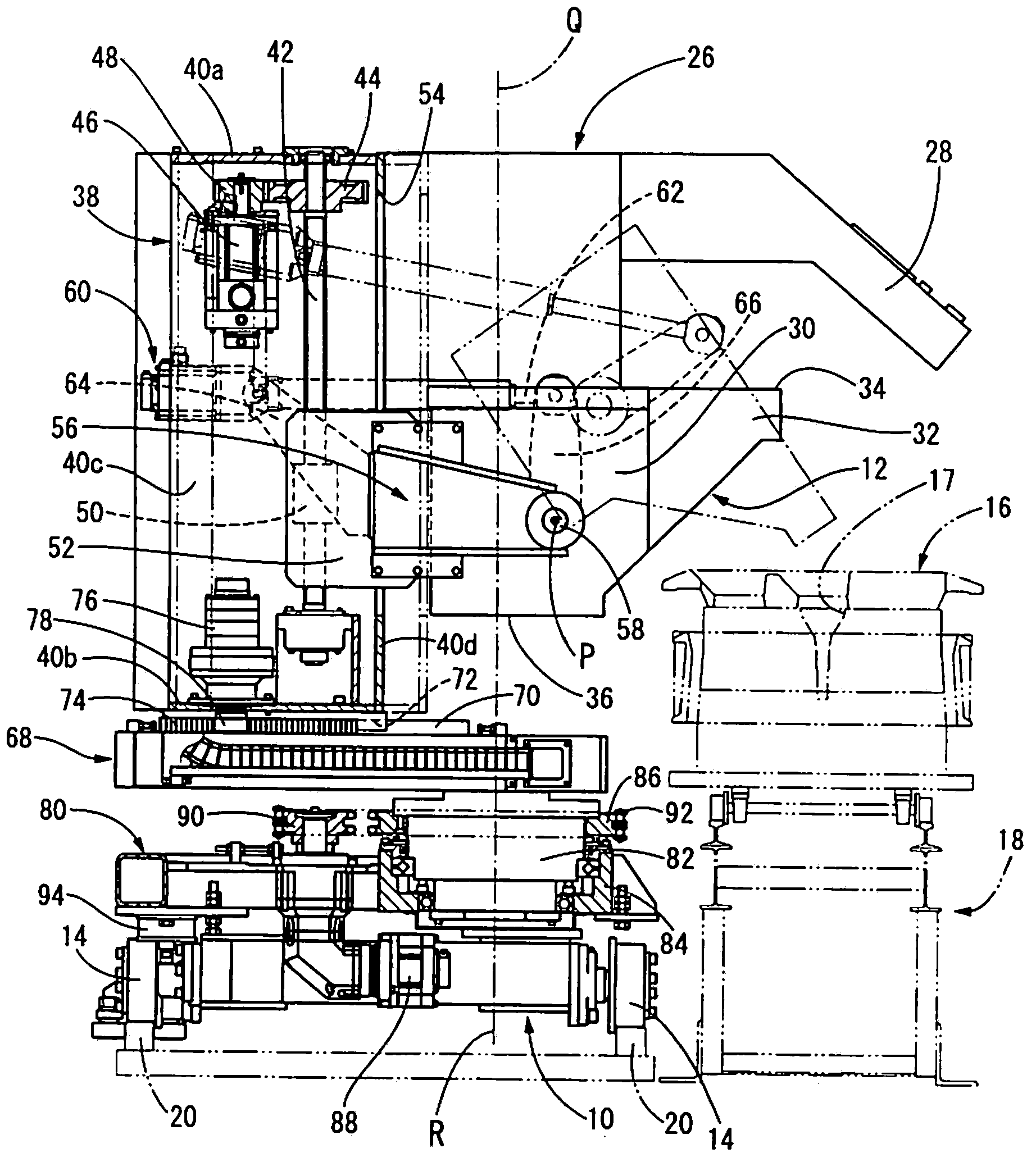

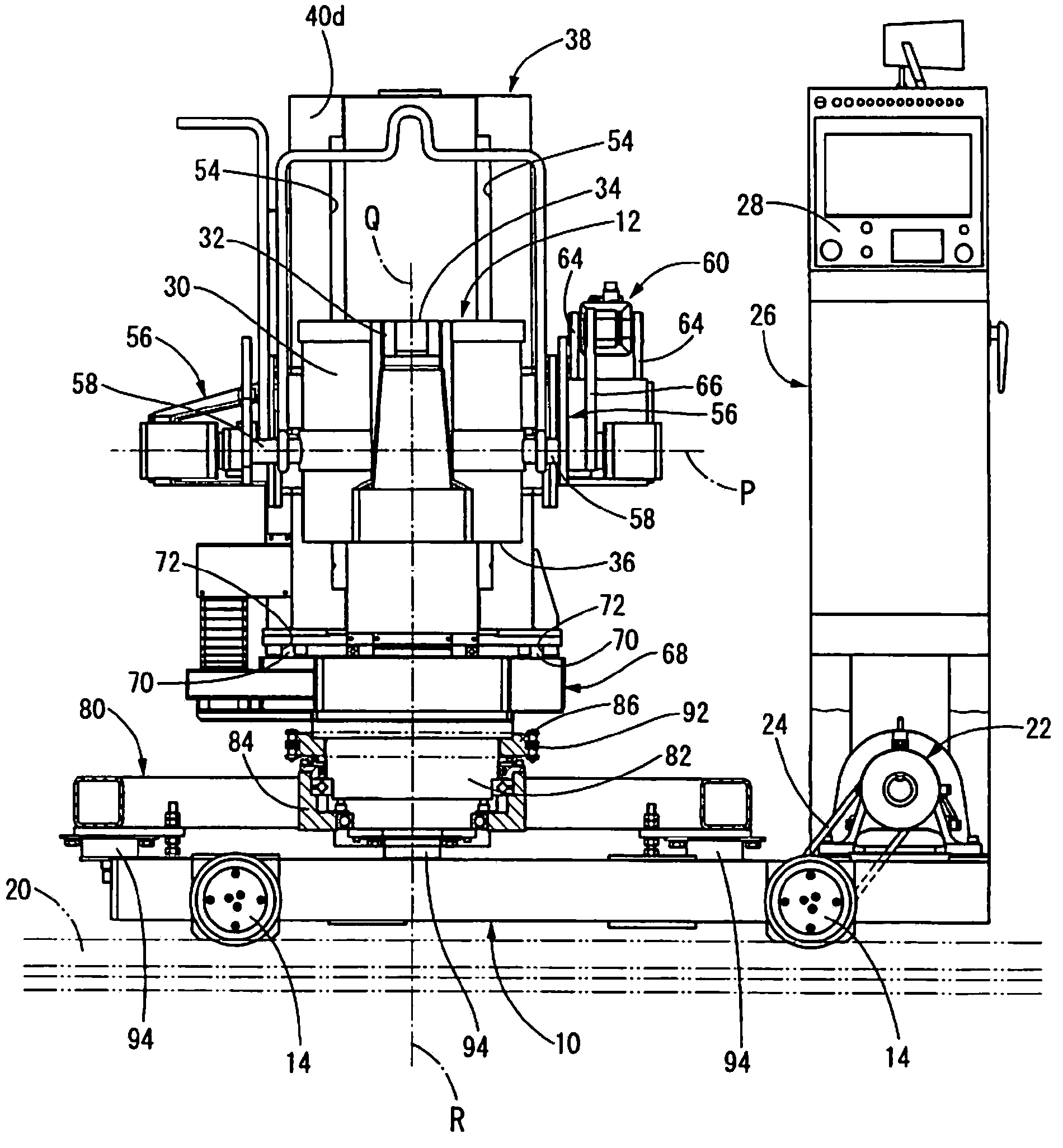

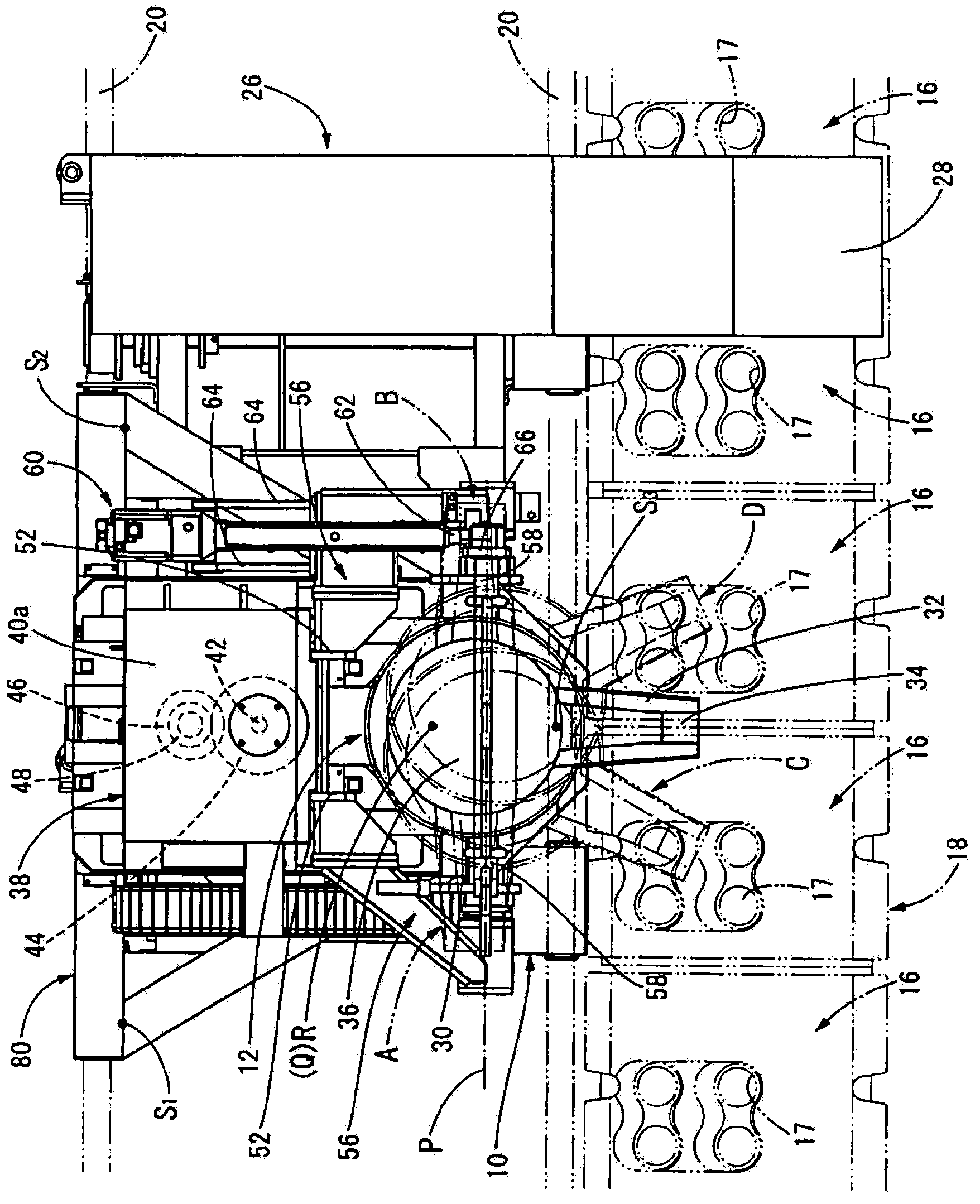

[0031] First of all, Figure 1 to Figure 3 The front view form, the right side view form, and the top view form of the automatic pouring apparatus according to an embodiment of the automatic casting apparatus having the structure of the present invention are respectively shown. It is also clear from these figures that the automatic pouring device has a trolley 10 that can move freely and a ladle 12 installed on the trolley 10.

[0032] In more detail, such as figure 1 with figure 2 As shown, the trolley 10 has four (here only three) wheels 14, 14, and 14 respectively located in one of the front, rear, left, and right directions. In addition, the trolley 10 is mounted on two traveling rails 20, 20 via four wheels 14, 14, 14 (in Figure 1 to Figure 3 It is indicated by a double-dot chain line in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com