Rubber of rubber track board of railway crossing

A technology of rubber beading and track boards, applied in the field of rubber beading, can solve the problems that construction workers are not easy to concentrate on exerting force, rubber materials are easy to deteriorate and break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with accompanying drawings.

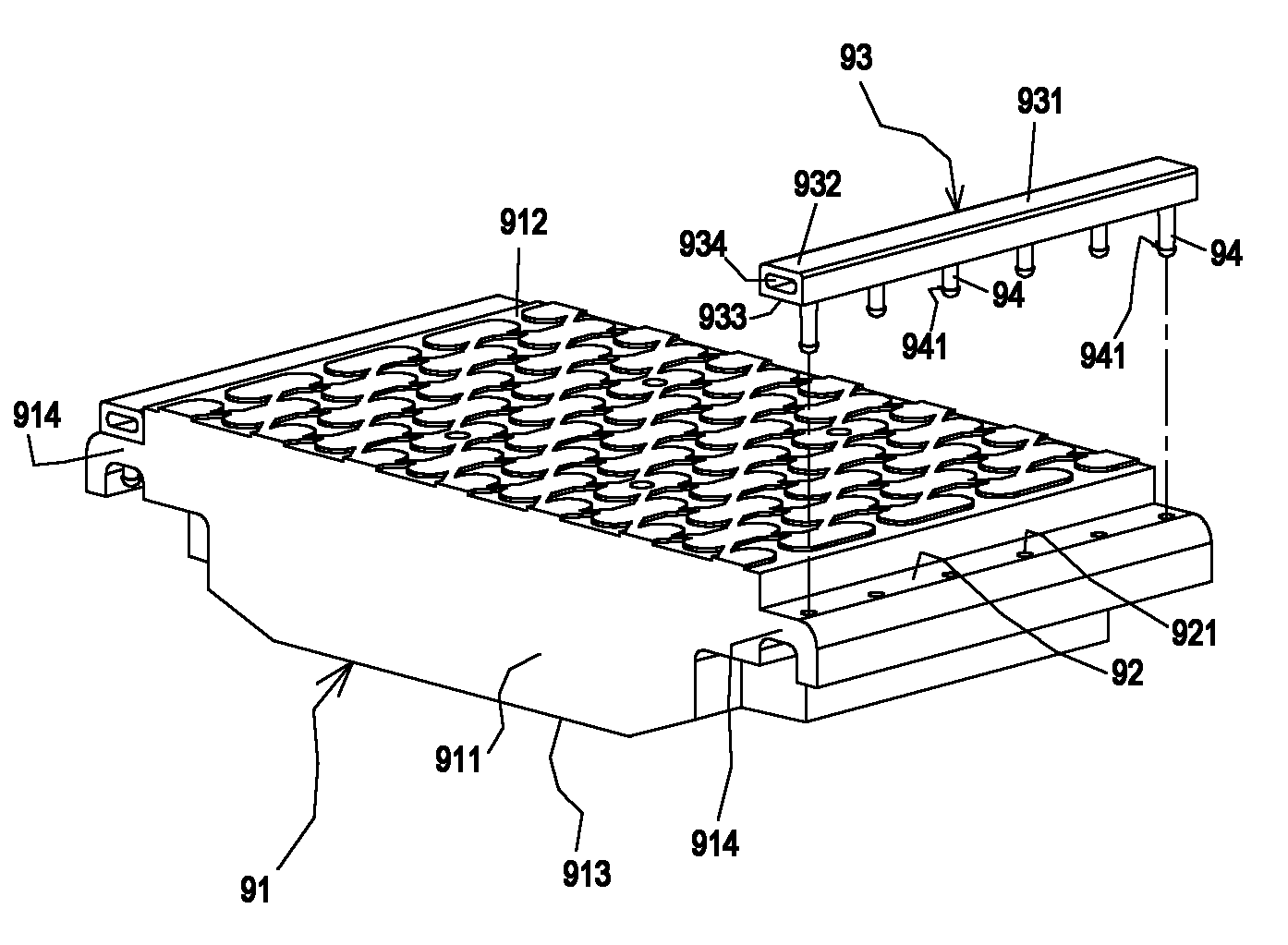

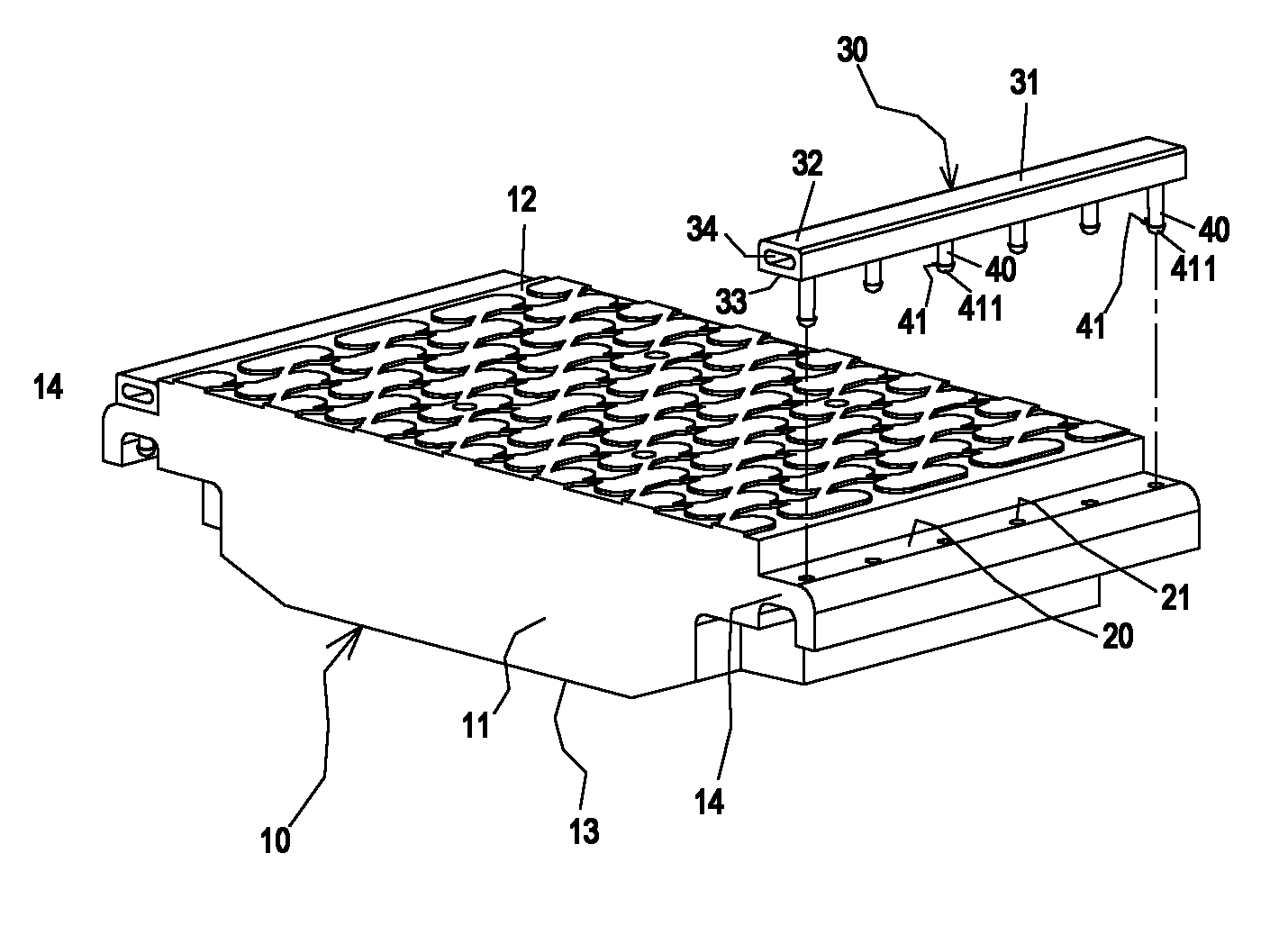

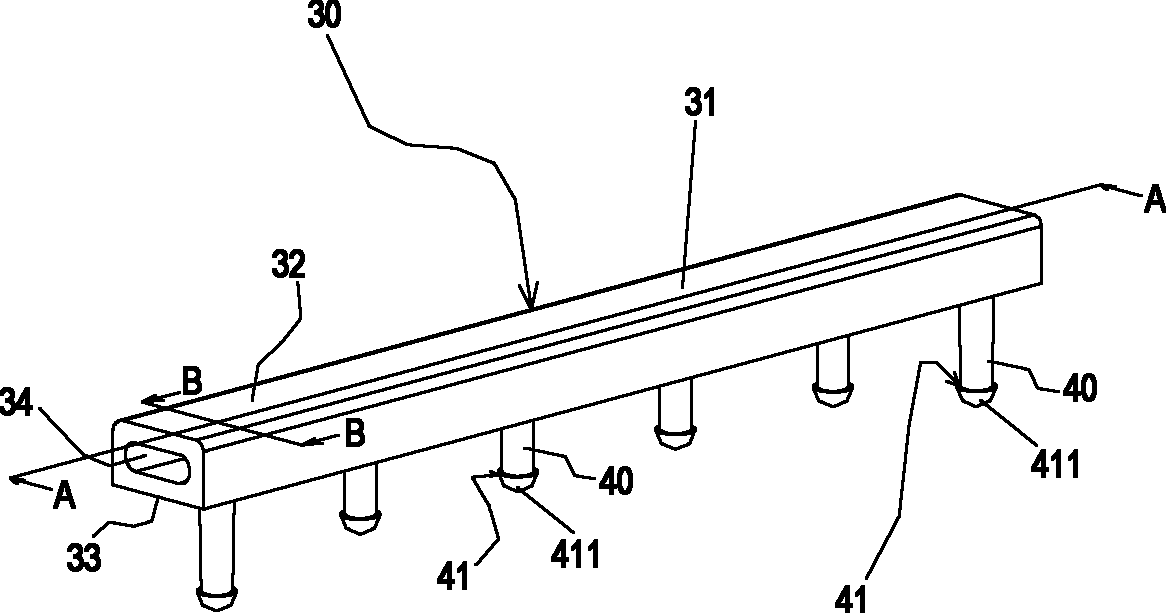

[0030] The present invention proposes a rubber bead 30 for fixing the rubber track 10 of the railway level crossing. The railway level crossing has two parallel rails. The rubber track 10 is installed between the two parallel rails and can fill the space between the two parallel rails. The recessed area between makes the rubber track plate 10 flush with the two parallel rails, so that people and cars can pass through the railway level crossing more smoothly; figure 2 It can be seen that the rubber road plate 10 includes a plate main body 11 and two grooves 20, the road plate main body 11 has a top surface 12, a bottom surface 13 and two stepped parts 14, and the two stepped parts 14 are respectively formed on the road plate main body 11 corresponds to each outer side of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com