A kind of motorcycle control composite clutch

A composite, clutch technology, applied in friction clutches, clutches, mechanical drive clutches, etc., can solve the problems of time-consuming and labor-intensive repairing motorcycles, need to be replaced, and increase the cost of motorcycle use, so as to avoid damage and enhance power transmission. , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

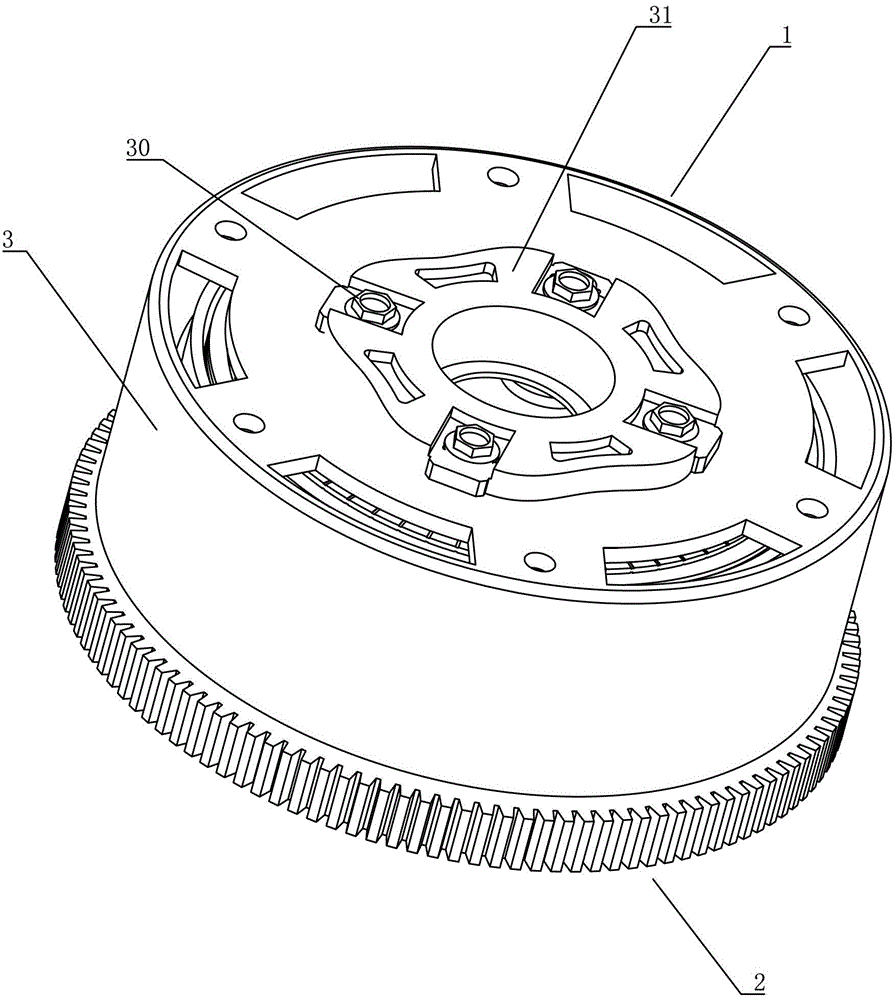

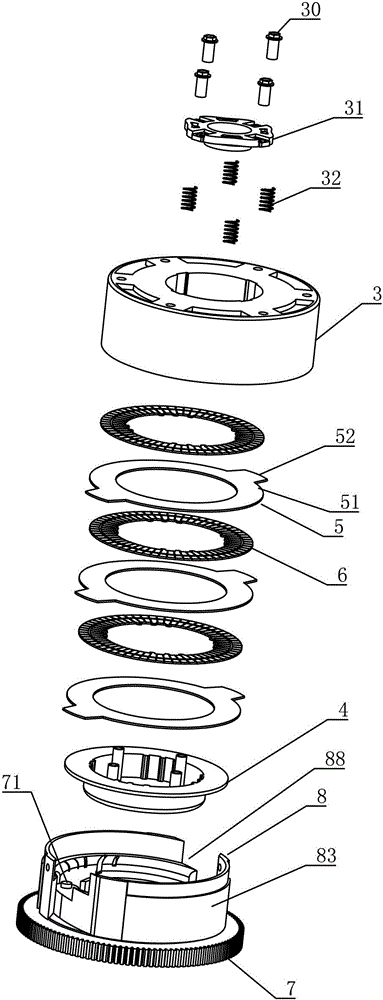

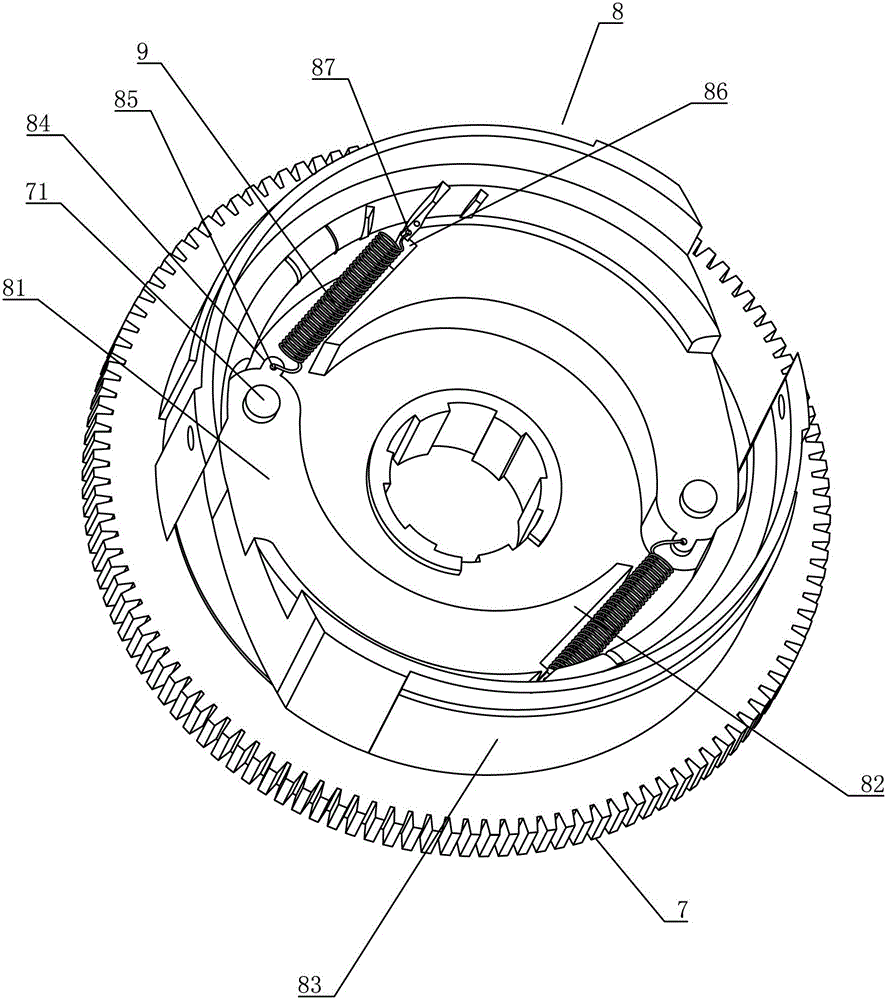

[0017] Such as Figure 1~Figure 3 As shown, a motorcycle-operated composite clutch includes a main clutch part 1 and an auxiliary clutch part 2. The main clutch part 1 of the present invention includes an upper pressure plate 3, an upper connecting plate 31, and a compression spring sleeved on a bolt 30. 32. The lower pressure plate 4, the driving friction plate 5 and the driven friction plate 6, the auxiliary clutch part 2 includes the driven gear 7, the shoe block 8 and the friction block 83 fixed on the outside of the shoe block 8.

[0018] One end of the upper platen 3 is open, the closed end of the upper platen 3 is provided with an upper connecting plate 31, the upper connecting plate 31 is connected with the lower platen 4 through a bolt 30, and a compression spring 32 is sleeved on the bolt 30, and the compression spring One end of 32 abuts against the bolt head of the bolt 30 , and the other end abuts against the upper pressure plate 3 , and between the upper pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com