Especially direct plug-in elements for vehicle controllers

一种插塞元件、直接的技术,应用在电气元件、连接装置的零部件、连接等方向,能够解决触点会磨损电方面、插塞连接振动运动、复杂布线结构等问题,达到可靠连接、小空间位置需求、简单装配的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

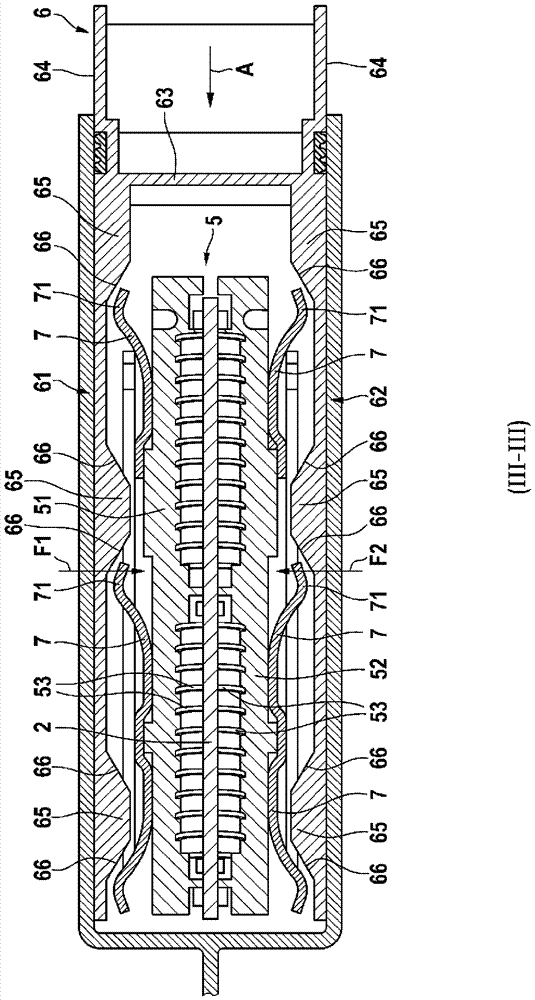

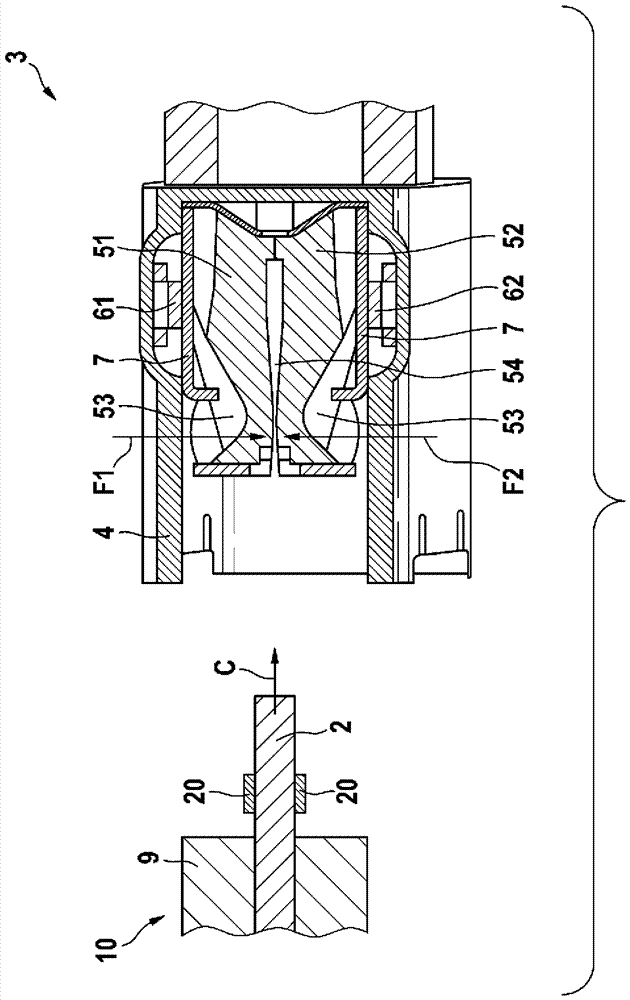

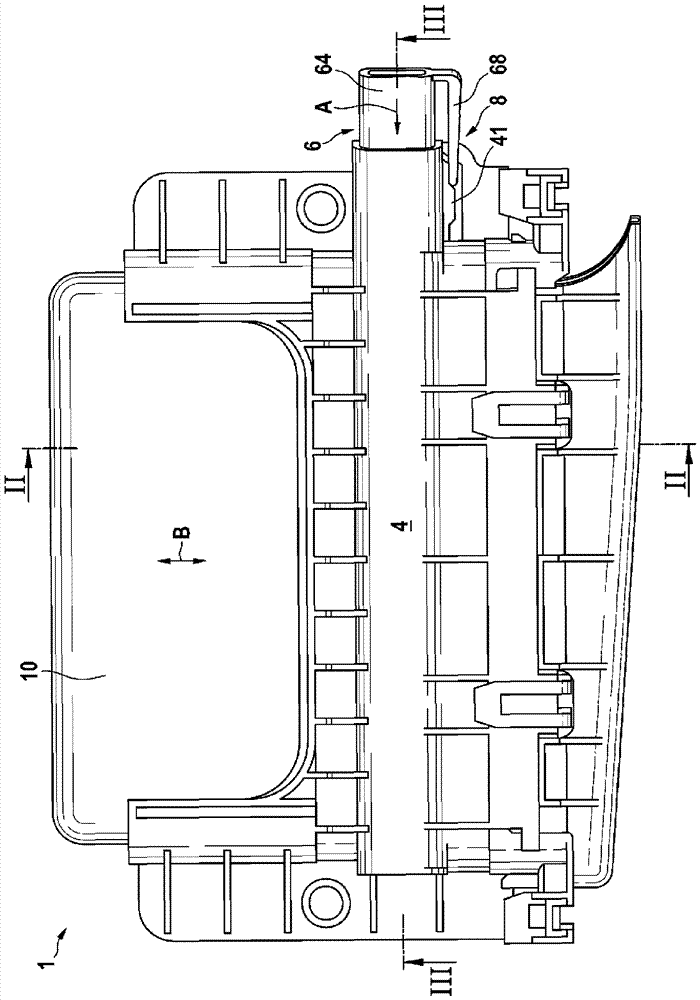

[0020] Refer below Figure 1 to Figure 4 An electrical device 1 and a direct plug-in element 3 according to an exemplary embodiment of the invention are described in detail.

[0021] The direct plug-in element 3 according to the invention comprises a housing, preferably made of plastic, and a two-part contact carrier 5 arranged in the housing 4 . The contact holder 5 includes a first contact holder part 51 and a second contact holder part 52 . The contact carrier parts 51 , 52 are arranged loosely in the housing. Protrusions (not shown) in the housing prevent the loosely arranged contact carrier parts 51 , 52 from falling out of the housing 4 . In this case, the play of the loosely arranged contact carrier parts 51 , 52 in the housing 4 is arranged in such a way that the contact carrier parts 51 , 52 cannot fundamentally change their direction, for example rotate 360° horizontally and vertically, but instead Keep its main orientation. A plurality of direct contacts 53 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com