Steering supporting welding fixture

A welding fixture and welding clamp technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex fixture structure, low production efficiency, inconvenient operation, etc., and achieve firm clamping of workpieces and convenient operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

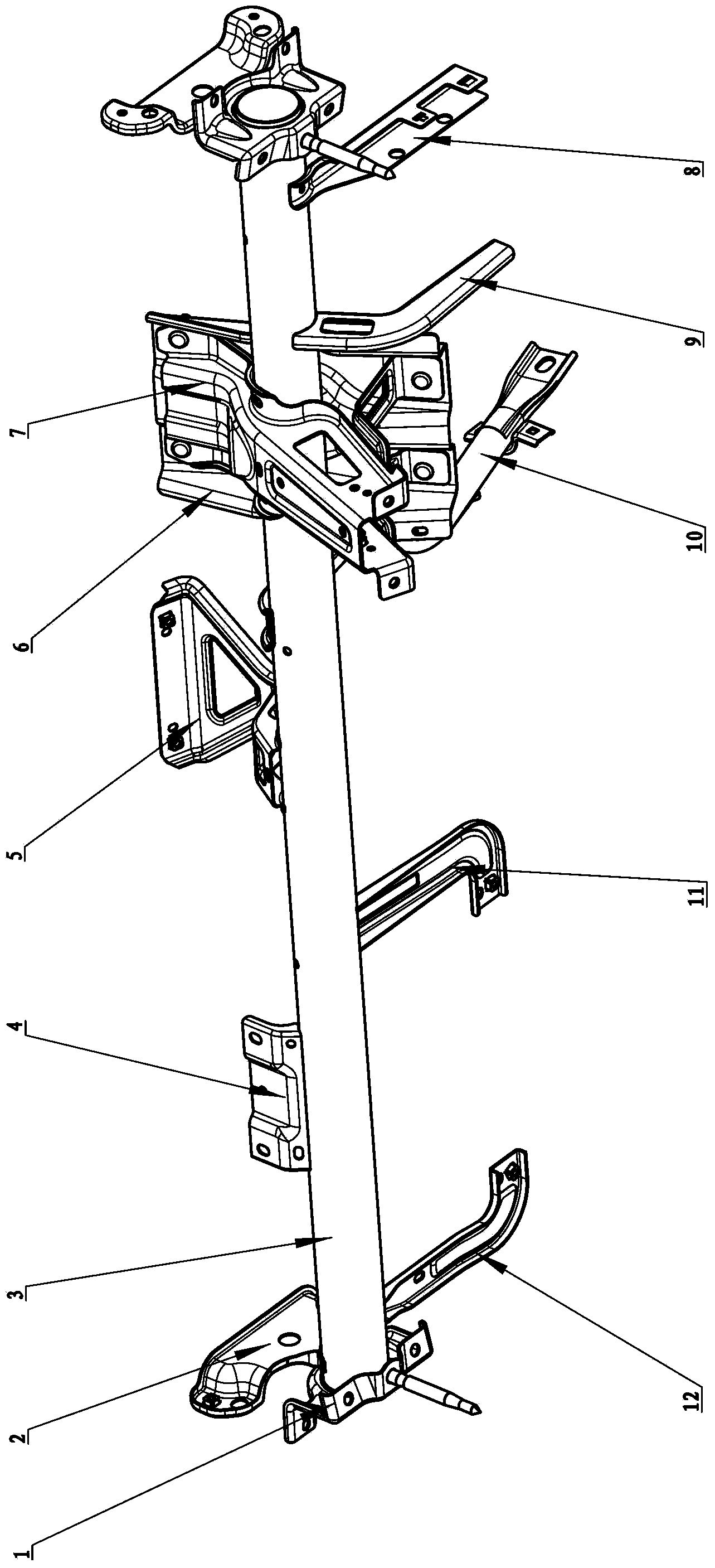

[0007] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a steering support welding fixture described in this embodiment includes a first positioning support member 2, a first pressing member 4, a second pressing member 5, a first positioning pressing member 6, a third pressing member Part 7, fourth pressing part 8, second positioning support part 9, reference panel 10, fifth pressing part 11, sixth pressing part 12, second positioning pressing part 13, third positioning pressing part 14 , the seventh pressing member 15 and two connecting fixed plates 1, the reference plate surface 10 is horizontally arranged, and the two ends of the reference plate surface 10 are respectively connected with a connecting fixed plate 1, and the plate surfaces of each connecting fixed plate 1 are Perpendicular to the upper surface of the reference plate surface 10, the first positioning support 2 and the second positioning support 9 are arranged side by side on th...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To describe this embodiment, the steering support welding clip described in this embodiment further includes a switch control board 3 , and the switch control board 3 is installed on one side of the reference plate surface 10 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com