Tire building machine feeding mechanism and feeding method

A tire building machine and driving mechanism technology, applied in the field of rubber machinery, can solve the problems of waste of resources, large overall layout space, complicated installation and operation, etc., and achieve the effects of optimized stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

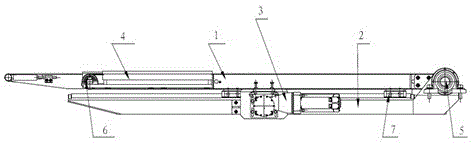

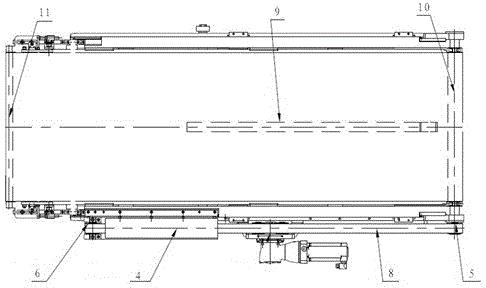

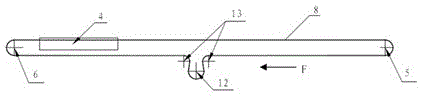

[0031] In this example, see the attached figure 1 , 2 , the present invention includes the common structure of the feeding device, specifically a feeding template 1 for placing and moving materials. The feeding template 1 is usually a rectangular flat plate, suitable for laying materials. The feeding template 1 can also include a frame through which related accessories can be fixed, such as the clutch mechanism 4 and the like. The feeding template 1 is placed on the fixed frame body 2 as a whole, and the feeding template 1 slides forward and backward on the fixed frame body 2, so that the materials laid on the feeding template 1 are suitable for bonding on the drum. In order to realize the sliding of the feeding template 1, a driving mechanism 3 needs to be provided. Unlike the traditional driving method, in this embodiment, the driving mechanism 3 cooperates with the timing belt 8 to realize the control of the feeding template 1, specifically the driving mechanism 3 Control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com