Multifunctional binding machine

A binding machine and multi-functional technology, applied in binding and other directions, can solve the problems of wasting materials and occupying space, and achieve the effect of convenient use and saving office space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

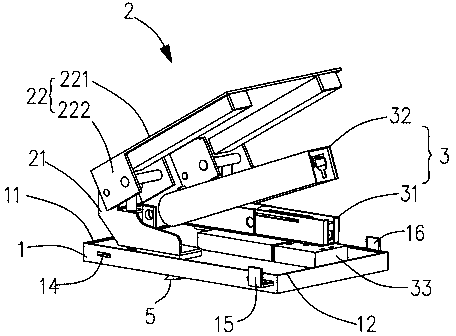

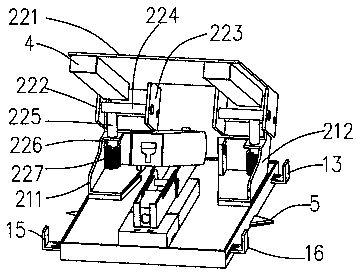

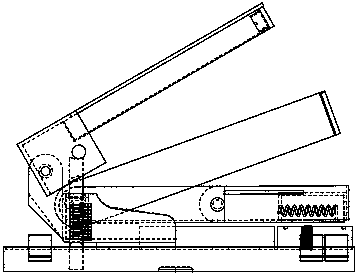

[0020] Such as Figure 1 to Figure 3 As shown, in one embodiment, the multifunctional binding machine mainly includes a base 1 and a puncher 2 and a stapler 3 fixed on the base 1 . Wherein, the base 1 is in the shape of a rectangular plate, and the punching entrance of the puncher 2 , that is, the paper entrance and exit, is close to the first end 11 of the base 1 . The staple mouth of the stapler 3 is close to the second end 12 of the base 1 . The second end 12 is opposite to the first end 11 .

[0021] The hole punch 2 includes a bracket 21 fixed on the first end 11 of the base and a pressing plate 22 pivotally connected to the bracket. The bracket 21 has an L-shaped structure, and its bent outer surface is notched or arc-shaped, and a gap is formed between the lower surface of the bracket 21 near the first end 11 and the base 1, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com