Pressure roller assembly

A technology of components and pressure rollers, applied in the field of pressure roller components, can solve the problems of inaccurate positioning and transmission, back and forth movement, left and right movement of conveyed objects, etc., and achieves the effect of good effect, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

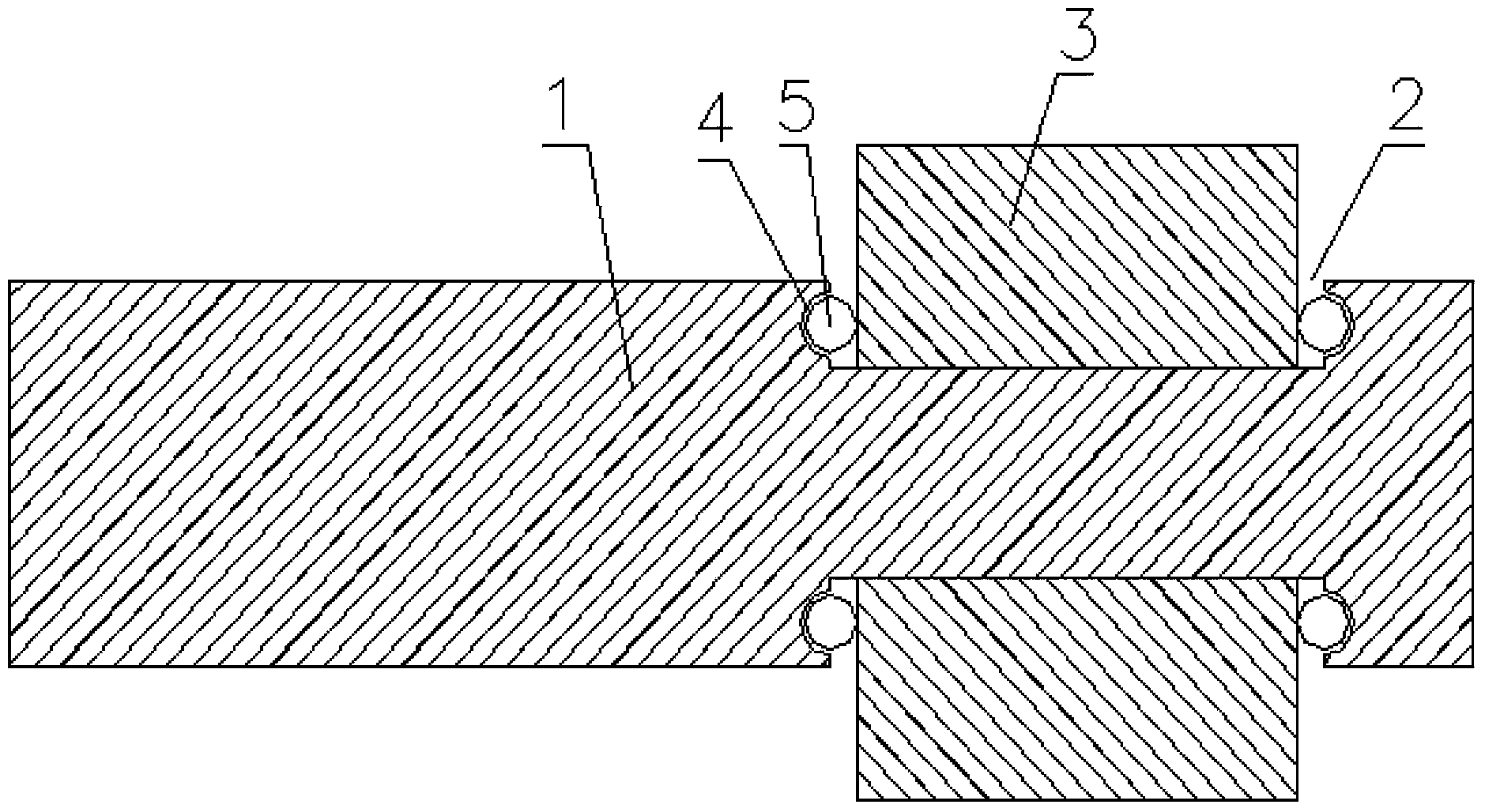

[0011] Such as figure 1 The pressure wheel assembly shown includes a connecting rod 1, a groove 2 is provided on the connecting rod 1, a roller 3 is set on the groove 2, and an inwardly recessed hemispherical groove 4 is provided on both sides of the groove 2, and the hemispherical groove Steel ball 5 is placed in 4, and steel ball 5 tops on the side of roller 3, wherein hemispherical groove 4 circles around the side of groove 2, and hemispherical groove 4 on the groove communicates with hemispherical groove 4 to form an annular hemispherical groove.

[0012] The basic principles, main features and advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap